Anti-pollution hollow fiber membrane biological reaction assembly

A biological reaction, fiber membrane technology, applied in the field of water treatment, can solve the problems of turbidity of the effluent, damage to the membrane filaments, etc., and achieve the effects of high water production efficiency, long service life, not easy to break and fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

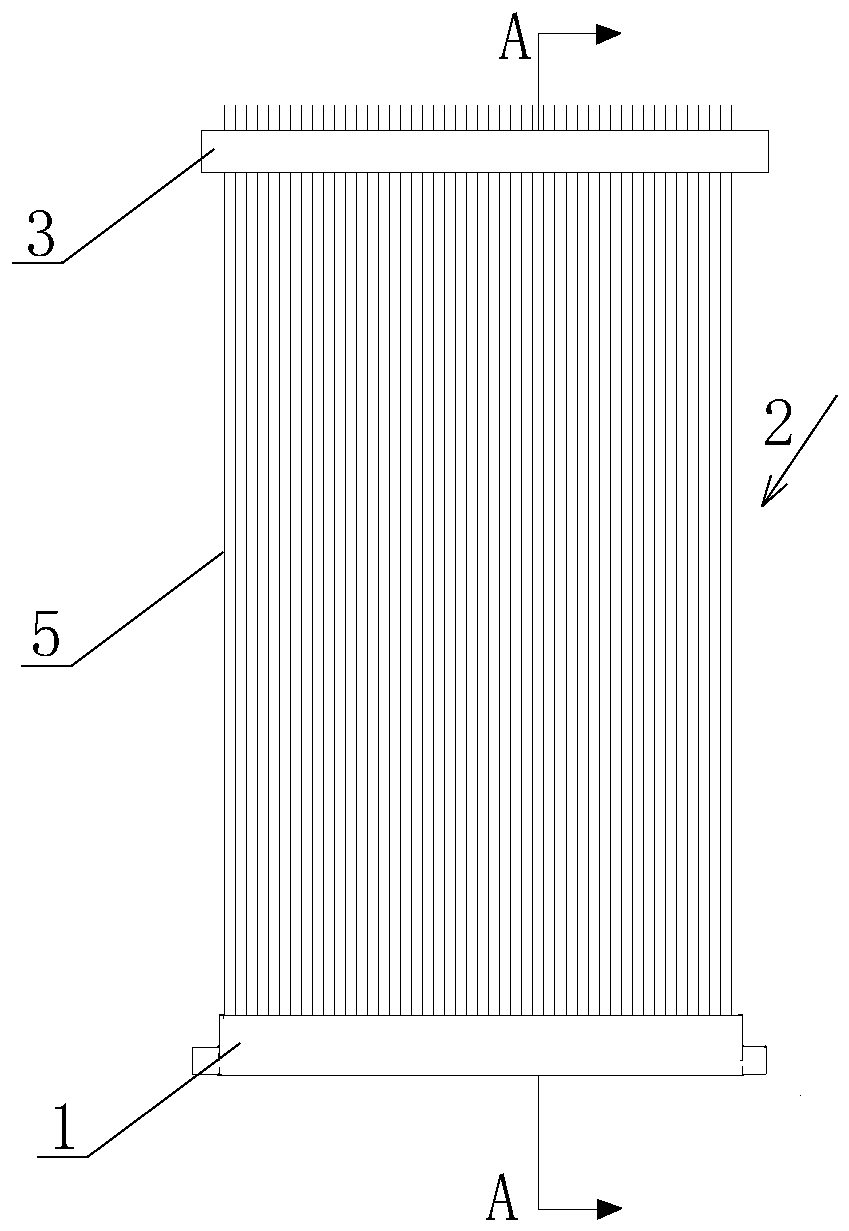

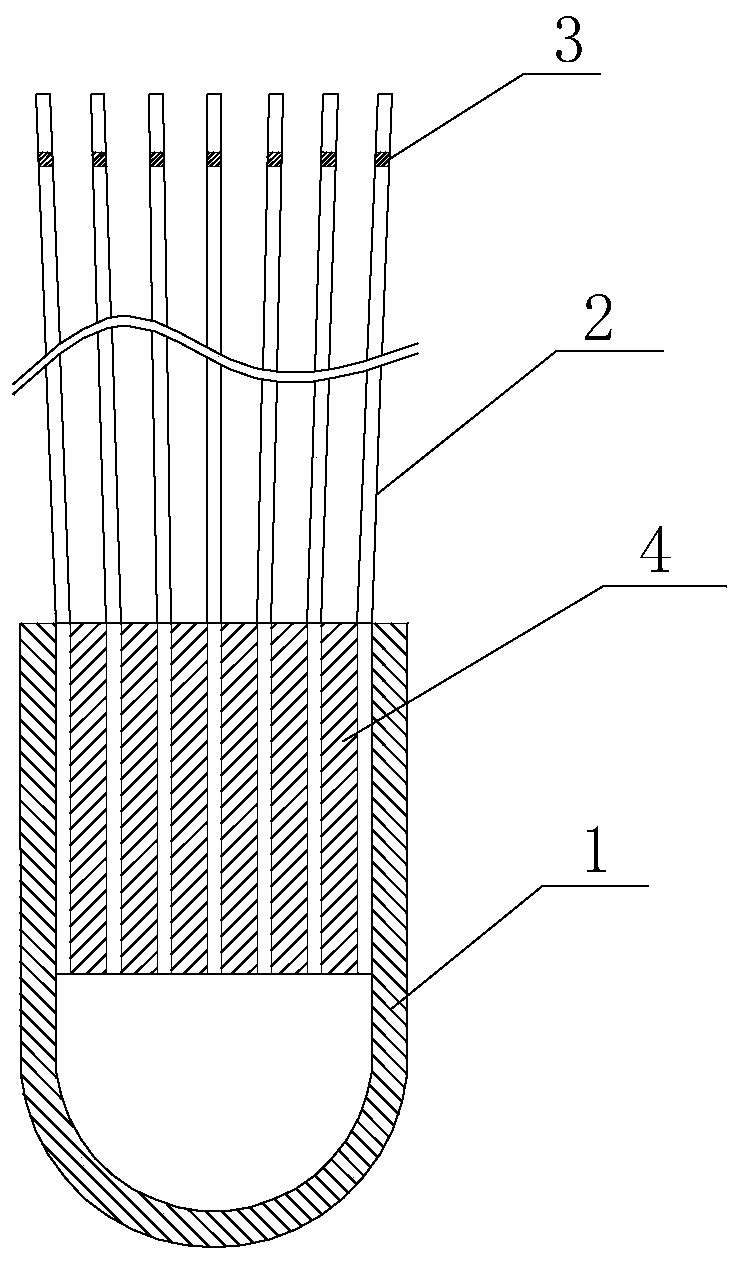

[0024] An anti-fouling hollow fiber membrane bioreaction module, as attached figure 1 , 2 As shown, the water collection box 1 and 7 hollow fiber membranes 2 are included. The water collection box 1 is located at the bottom, and the hollow fiber membranes 2 are arranged and packaged in the water collection box 1. The inner wall of the lower end of the hollow fiber membrane filament 5 is unblocked. The water collecting box 1 forms a lower potting layer 4, and the lower potting layer 4 is potted with resin, and the resin is urea-formaldehyde resin. The top of each hollow fiber membrane 5 in the hollow fiber membrane 2 is closed, and the upper end of the hollow fiber membrane 2 has an upper end fixing layer 3 to fix the relative positions of the hollow fiber membranes 5 .

[0025] The membrane filaments 5 of the upper fixing layer 3 are fixed by resin sealing, and the width of the sealing resin is 5 cm. The resin is selected as urea-formaldehyde resin, and the strength of the r...

Embodiment 2

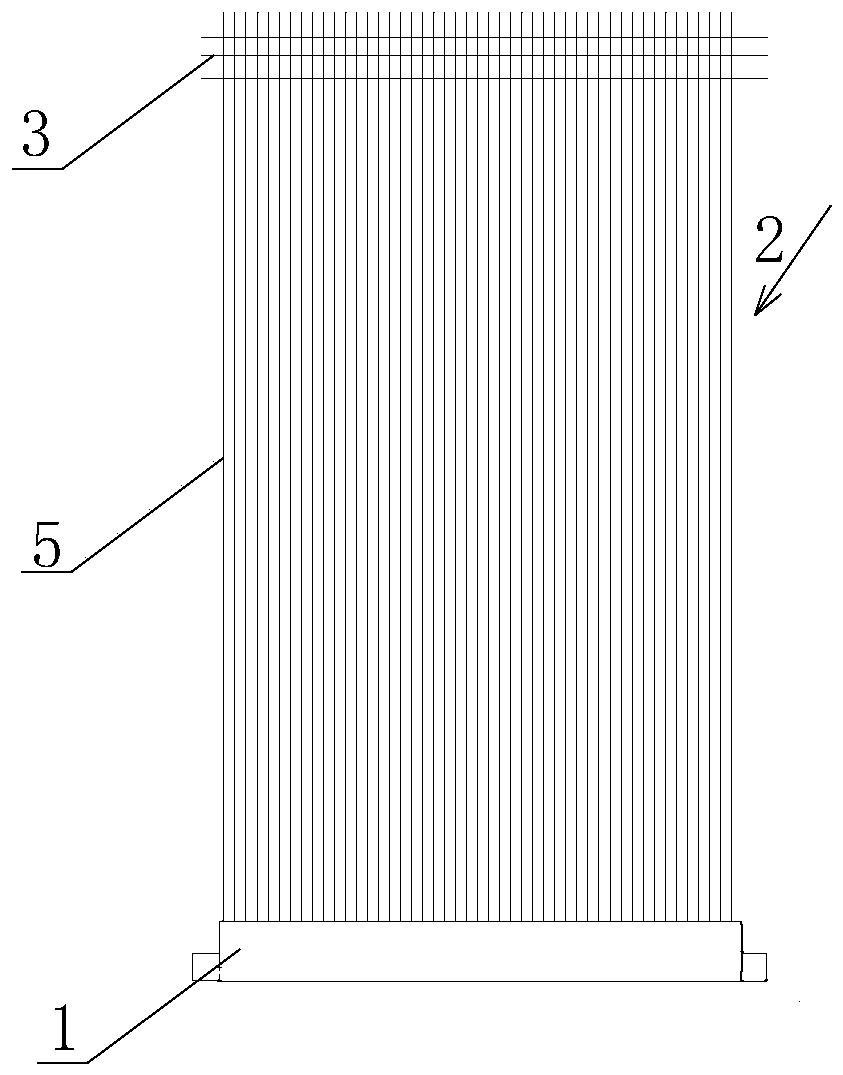

[0030] A kind of anti-pollution hollow fiber membrane bioreaction module other parts are the same as embodiment 1, the difference is: as attached image 3 As shown, the fiber rope is woven and fixed between the membrane filaments 5 of the upper fixing layer 3, the number of weaving of the fiber rope is 3, the fiber rope is selected from polyethylene, and the strength is more than 3kg.

[0031] The top of the upper fixed layer 3 is located at 8% of the longitudinal length of the hollow fiber membrane 2 from top to bottom.

[0032] The distance between the diaphragms in the upper fixing layer 3 is 5 mm, and the distance between the diaphragms in the lower potting layer 4 is 3 mm.

[0033] The membrane filaments in the hollow fiber membrane 2 are evenly arranged, and the distance between the membrane filaments is 0.1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com