Method for preparing polytitanium coagulant and application thereof

A technology of coagulant and organic titanium, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water pollutants, etc., can solve the unfavorable production of polytitanium coagulant dosage, long natural drying time, and corrosion of instruments To achieve stable and rapid coagulation effect, overcome hydrochloric acid corrosion, and excellent coagulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

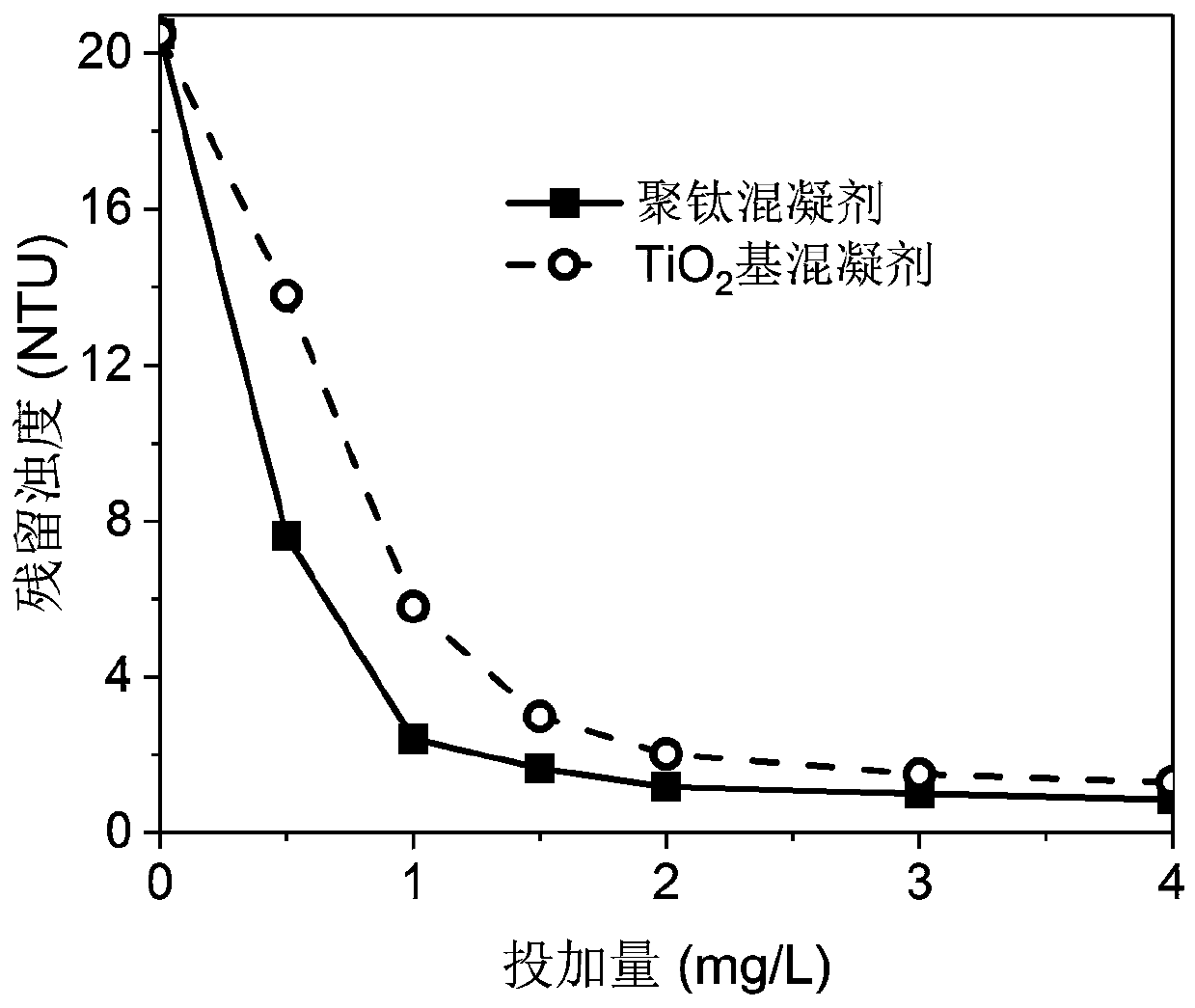

[0036] Example 1 Stable preparation of polytitanium coagulant and performance evaluation of turbidity removal

[0037] (1) Preparation of polytitanium coagulant

[0038] a) Mix 0-10mL ethanol and 0.1-0.7mL acetylacetone evenly, add 4.1mL isopropyl titanate, and then stir at 300rpm for 30min to obtain liquid A; the molar ratio of organic titanium alkoxide, alcohol and acetylacetone is 1: 0~12: 0.06~0.5;

[0039] b) Mix 0-5mL ethanol, 0.1-0.8mL deionized water and 0.4-1.2mL concentrated hydrochloric acid to form B solution; the molar ratio of organic titanium alkoxide, alcohol, deionized water and acid is 1:0-6: 3~6: 0.5~1;

[0040] c) Add liquid B to liquid A at a rate of 0.5 mL / min, and then stir at a rate of 300 rpm for 60 min to obtain a mixed solution;

[0041] d) The mixed solution is placed at room temperature of 20°C and dried naturally for 3 days to constant weight to obtain the polytitanium coagulant

[0042] According to different proportions of alcohol, they are ...

Embodiment 2

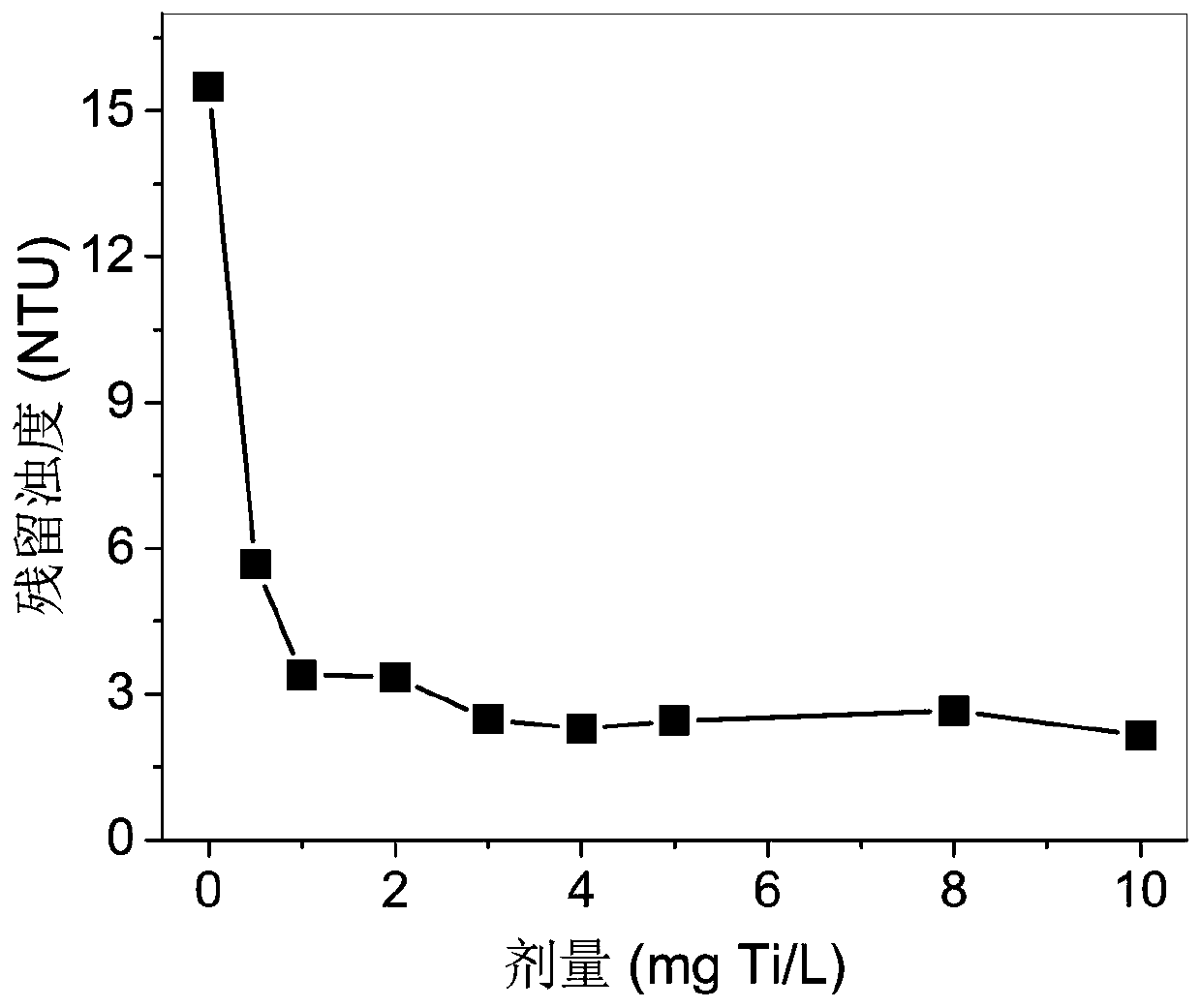

[0055] Example 2 Rapid preparation of polytitanium coagulant and performance evaluation of turbidity removal

[0056] (1) Rapid preparation of polytitanium coagulant

[0057] a) Mix 10mL of ethanol and 0.1mL of acetylacetone evenly, add 4.1mL of isopropyl titanate, and then stir at 300rpm for 30min to obtain liquid A;

[0058] The molar ratio of organic titanium alkoxide, alcohol and acetylacetone is 1:12:0.06;

[0059] b) Mix 5mL ethanol, 0.9mL deionized water and 0.9mL concentrated hydrochloric acid to form B solution;

[0060] The molar ratio of organic titanium alkoxide, alcohol, deionized water and acid is 1:6:6:0.75

[0061] c) Add liquid B to liquid A at a rate of 120 mL / min, and then stir at a rate of 300 rpm for 60 min to obtain a mixed solution;

[0062] d) Use a spray dryer (Shanghai Qiaofeng Industrial Co., Ltd., model QFN-8000S) to dry the mixed solution, and use a peristaltic pump to pump the mixed solution into the atomizer to heat and dry within a few second...

Embodiment 3

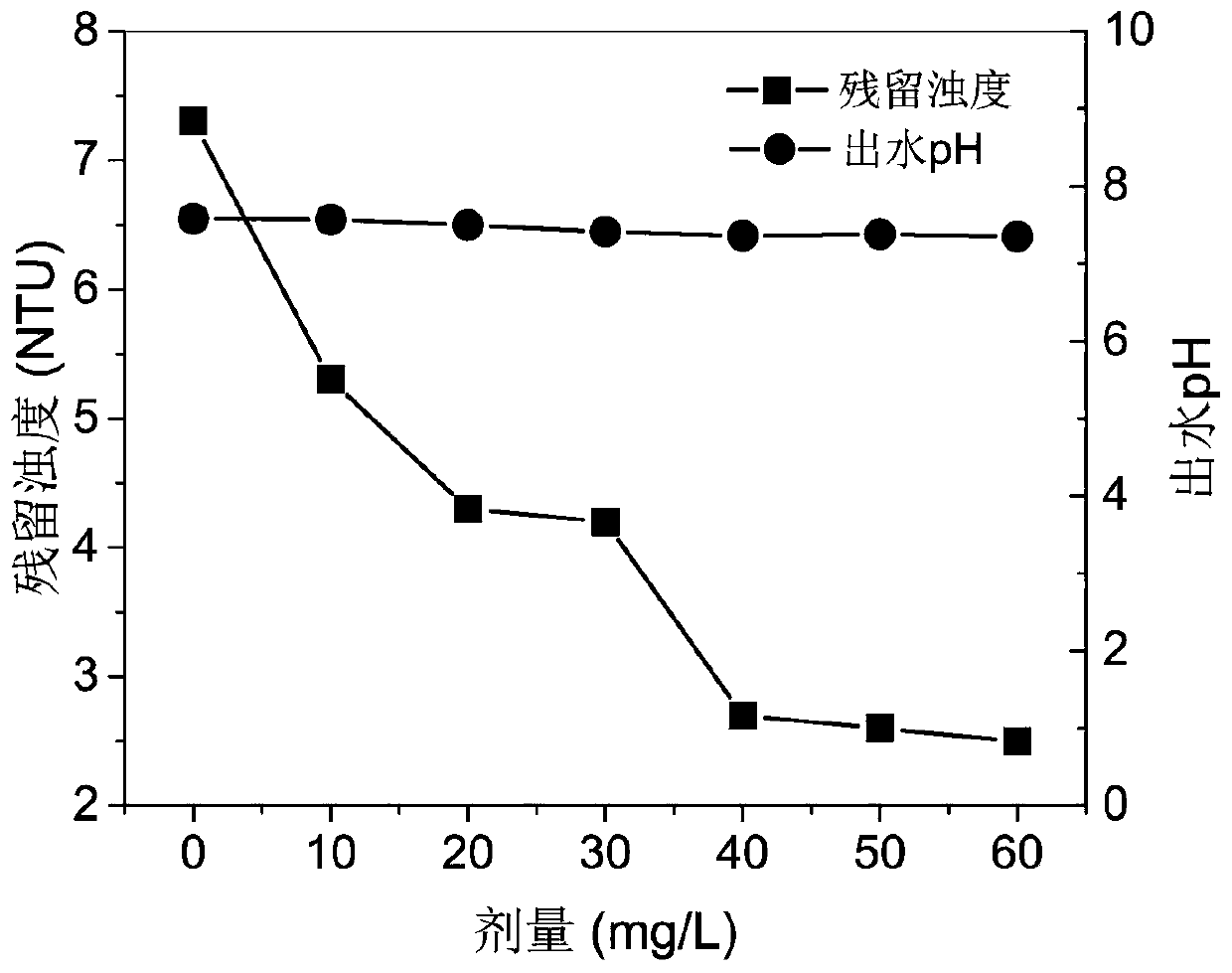

[0069] Example 3 Prepare polytitanium coagulant in large batches and evaluate the treatment effect on actual water samples (1) Prepare polytitanium coagulant in large quantities

[0070] a) Mix 200mL of ethanol and 3.5mL of acetylacetone evenly, add 164mL of isopropyl titanate, and then stir at 300rpm for 30min to obtain liquid A;

[0071] The molar ratio of organic titanium alkoxide, alcohol and acetylacetone is 1:6:0.06;

[0072] b) Mix 100mL ethanol, 34mL deionized water and 34mL concentrated hydrochloric acid to form B solution;

[0073] The molar ratio of organic titanium alkoxide, alcohol, deionized water and acid is 1:3:6:0.75

[0074] c) Add liquid B to liquid A at a rate of 120mL / min, and then stir at a rate of 300rpm for 60min to obtain a mixed solution;

[0075] d) Use a spray dryer to dry the mixed solution, and use a peristaltic pump to pump the mixed solution into an atomizer to heat and dry within a few seconds to obtain the polytitanium coagulant. The rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com