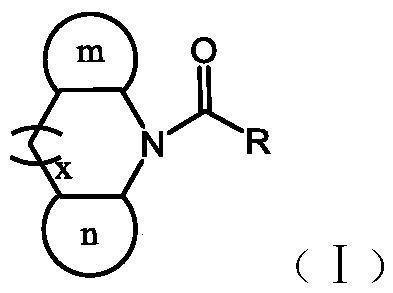

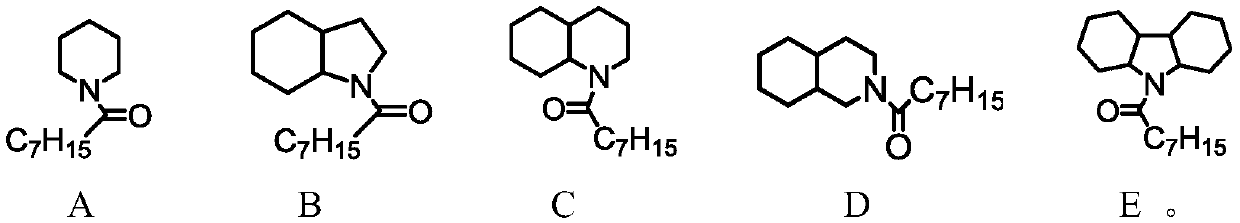

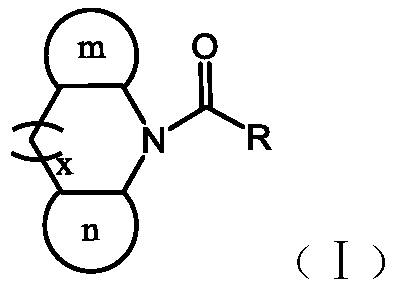

Naphthenic amide dephenolizing extractant and application thereof

A technology of dephenol extraction agent and naphthenic amide, which is applied in the direction of extraction of water/sewage treatment, water pollutants, water/sludge/sewage treatment, etc. It can solve the problems of unsuitability, pungent taste, and high toxicity of reagents. Achieve the effects of easy recycling, less pungent odor, and less loss of extractant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The volatile phenol content of the raw water of a coal gasification wastewater is 5682mg / L, the pH value is 8.32, the pH value of the wastewater is adjusted to 7, the ratio of wastewater to extraction agent is 4:1, it enters the extraction device, the reaction temperature is room temperature, and it undergoes two-stage extraction. The phenol-containing extract phase is added with 8% NaOH solution, the ratio of the extract phase to the lye is 4:1, the extractant is separated and recovered in the stripping device, the reaction temperature is 55°C, and the stripping is carried out in three stages. The volatile phenol content of the treated water sample was determined to be 33.14 mg / L, the removal rate was 99.1%, and the recovery rate of the extractant was 99.97%.

Embodiment 2

[0045] The volatile phenol content of the raw water of a blue charcoal wastewater is 4711mg / L, the pH value is 8.55, the pH value of the wastewater is adjusted to 7, the ratio of wastewater to extraction agent is 5:1, and it enters the extraction device, the reaction temperature is room temperature, and it undergoes two-stage extraction. The phenol-containing extract phase is added with NaOH solution with a mass concentration of 8%, the ratio of the extract phase to the lye is 4:1, the extractant is separated and recovered in the stripping device, the reaction temperature is 45°C, and three stages of stripping are performed. The volatile phenol content of the treated water sample was determined to be 61.24mg / L, the removal rate was 98.7%, and the recovery rate of the extractant was 99.98%.

Embodiment 3

[0047] The volatile phenol content of the wastewater produced by a needle coke project is 12596mg / L, the pH value is 8.28, the pH of the wastewater is adjusted to 5, the ratio of wastewater to extraction agent is 2:1, the extraction device, the reaction temperature is room temperature, and three stages of extraction . The phenol-containing extract phase is added with 8% NaOH solution, the ratio of the extract phase to the lye is 4:1, the extractant is separated and recovered in the stripping device, the reaction temperature is 55°C, and the stripping is carried out in three stages. The volatile phenol content of the treated water sample was determined to be 239.32 mg / L, the removal rate was 98.1%, and the recovery rate of the extractant was 99.96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com