Acid-base tank

A technology of acid-base and tank body, which is applied in the field of acid-base tank, which can solve the problems of low mixing efficiency and achieve the effects of reliable mixing, improved uniformity and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

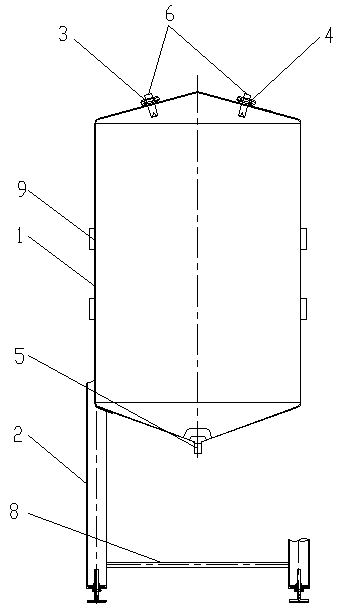

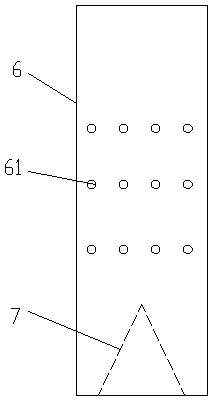

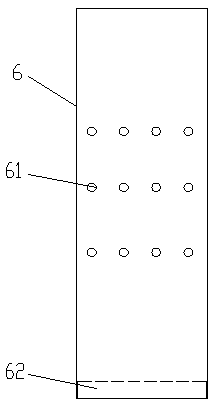

[0020] The invention as Figure 1-5 As shown, a tank body 1 is included, the bottom of the tank body is provided with legs 2, the top two ends of the tank body are symmetrically provided with an acid liquid inlet 3 and an alkali liquid inlet 4, and the bottom center of the tank body is provided with an outlet 5 The acid liquid inlet and the lye inlet are respectively provided with a cloth assembly, the cloth assembly includes a feed pipe 6 and a material guide body 7, and the feed pipe is located in the acid liquid inlet and the lye inlet, and the The material guide body 7 is arranged in the feed pipe 6, the said material guide body comprises a conical cover 71, the edge of the said conical cover is provided with a ring 72, said conical cover and the circular arc are respectively provided with leakage holes 73;

[0021] Wherein, a perforation 61 is provided around the feed pipe 6 located in the tank.

[0022] In the working process of the present invention, cloth components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com