Bidirectional deep machining device

A technology of processing device and transmission device, which is applied in feeding device, metal processing equipment, device for fixing grinding wheel, etc., can solve the problem of not being suitable for processing both ends of pipe, achieve overall stability and good consistency, improve production efficiency, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] The technical scheme adopted in the present invention is:

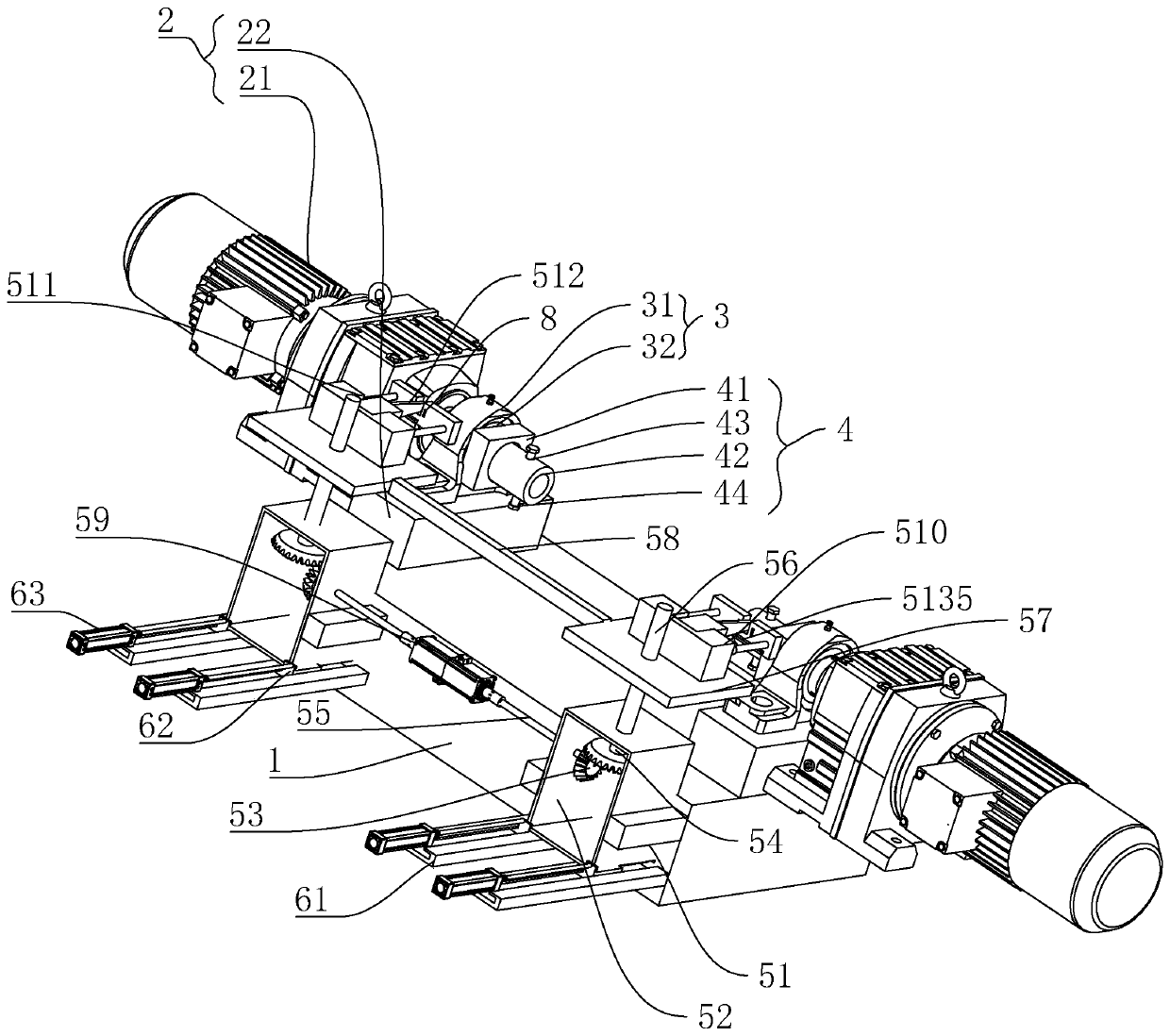

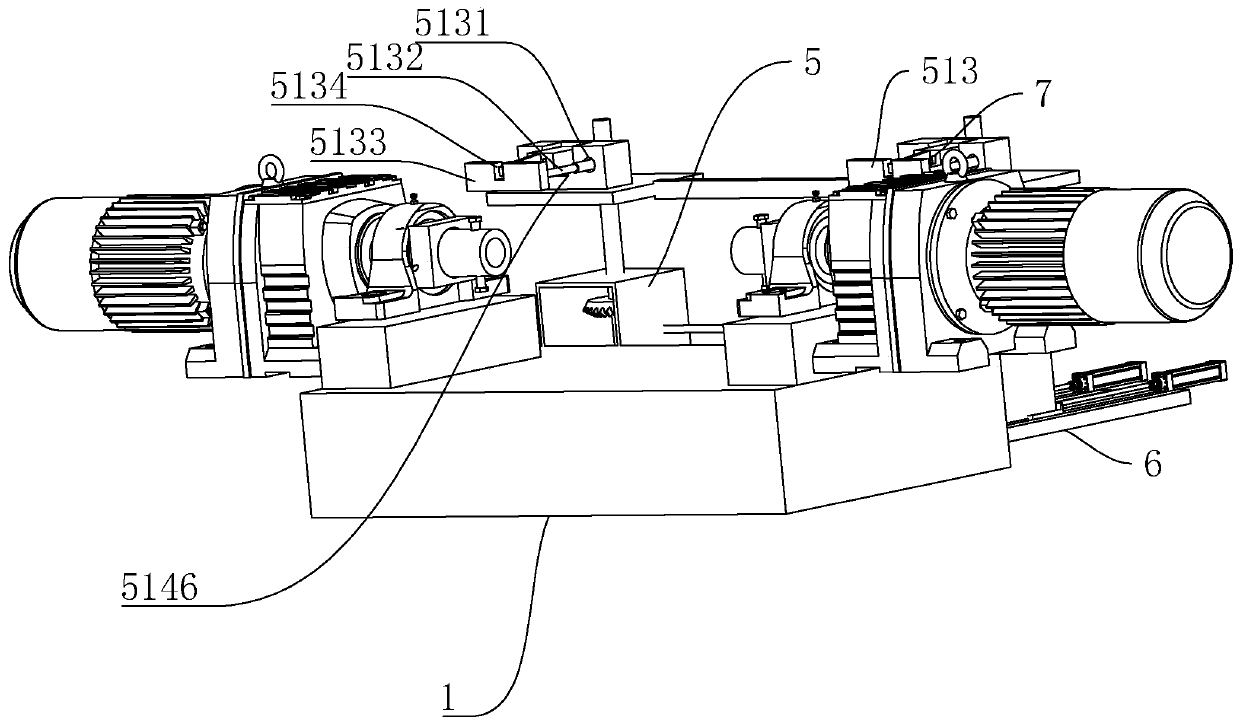

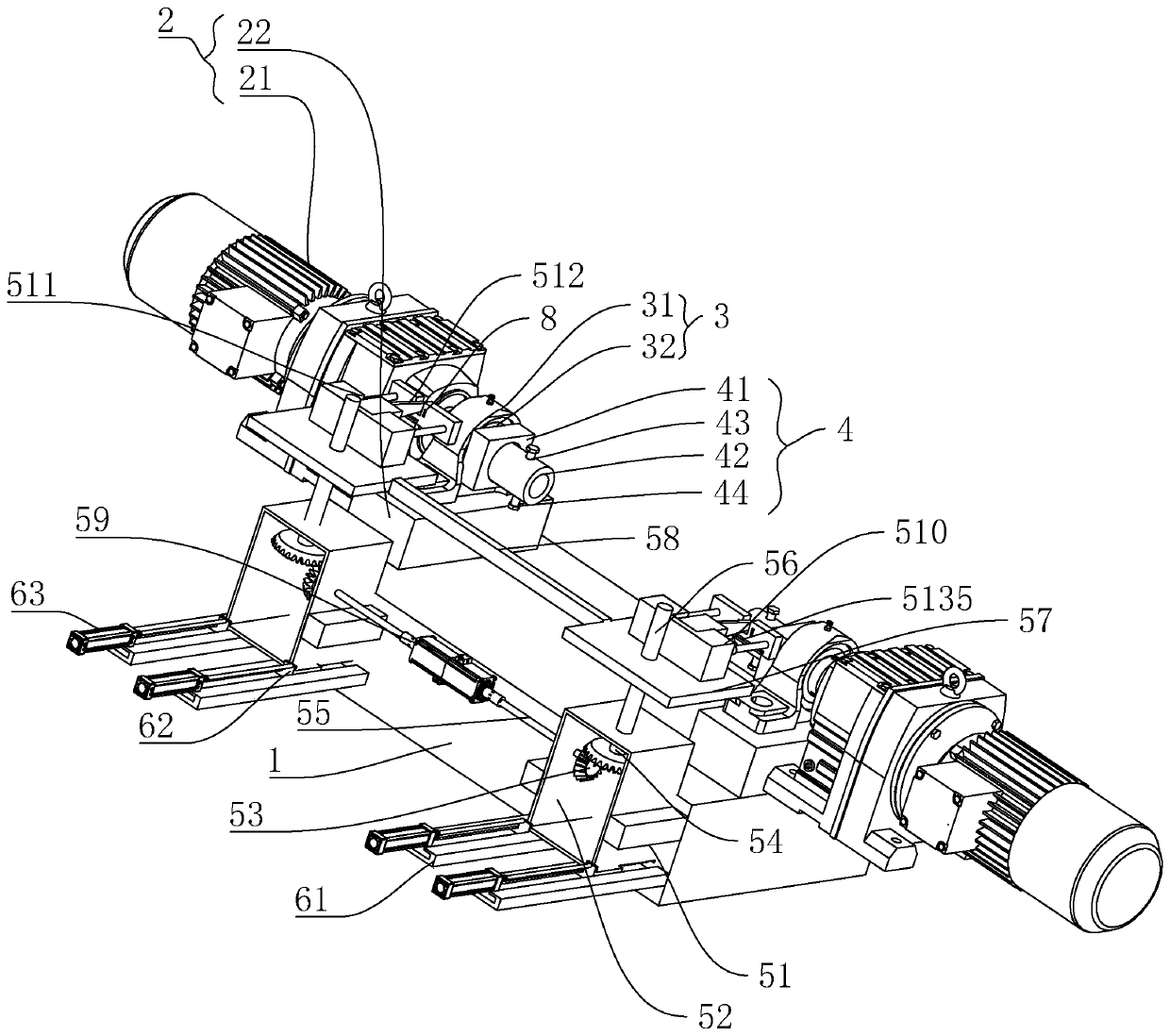

[0026] A two-way deep processing device, such as figure 1 and figure 2 As shown, the body 1 is included, and a rotating device 2 is provided on one side of the body 1. The rotating device 2 includes a transmission motor 21 provided on one side of the body 1 and a connecting block 22 connected to the transmission device 3 on the body 1. The connecting block 22 A transmission device 3 is connected to it, and the transmission device 3 includes a transmission frame 31 located on the connection block 22 and a rotating bearing 32 located on the transmission frame 31 and connected to the outlet of the transmission motor 21 . The body 1 is provided with a fixing device 4 connected with the rotating bearing 32. The fixing device 4 includes a fixed block 41 connected with the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com