Tinning machine for battery wire joints

A technology of wire joints and tin machines, which is applied in the direction of tin feeding devices, welding equipment, welding/welding/cutting items, etc., can solve the problems of wire skin damage, low efficiency, conduction, etc., and achieve avoiding damage and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

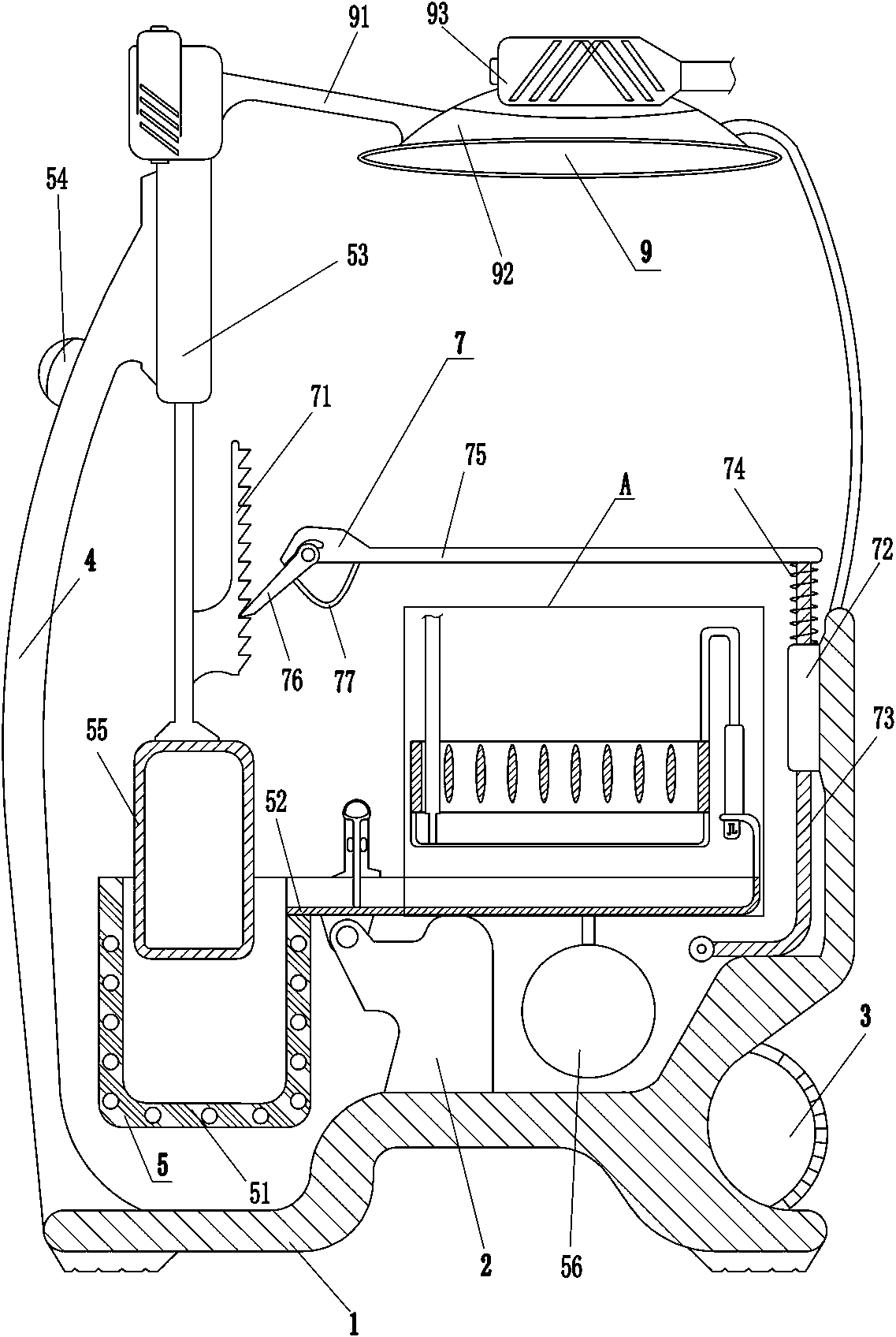

[0026] A tinning machine for battery wire joints, such as Figure 1-2 As shown, it includes an organic base 1, a fixed plate 2, a vertical rod 4, a tinning mechanism 5, and a tin immersion mechanism 6. The top of the machine base 1 is welded with a fixed plate 2 and a vertical rod 4, and the vertical rod 4 is located on the left side of the fixed plate 2. The fixed plate 2 is provided with a tinning mechanism 5, which is used to dissolve the tin bar into liquid tin, and the tinning mechanism 5 is provided with a tin-immersing mechanism 6, which is used to soak the wire in liquid tin .

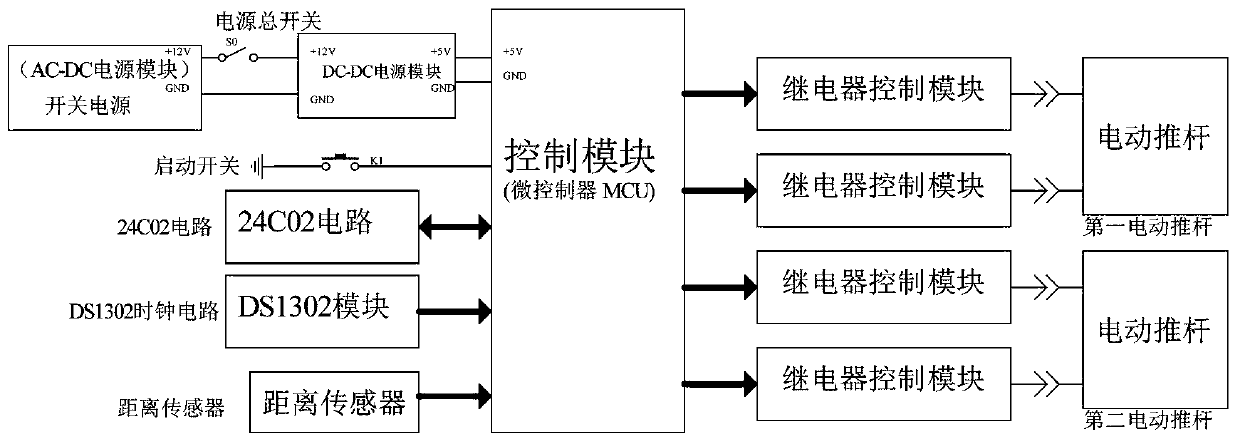

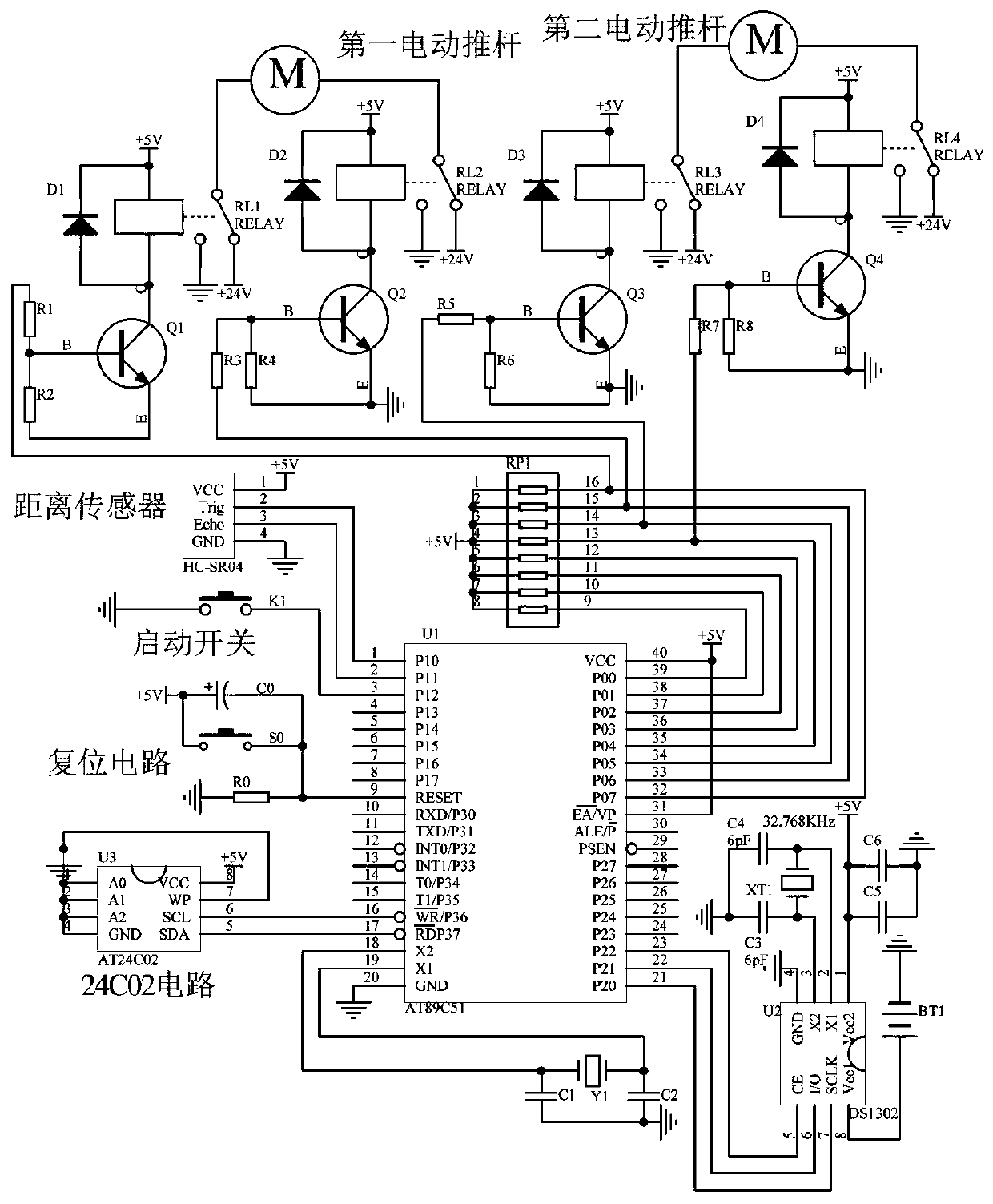

[0027] It also includes a control module, and both the tinning mechanism 5 and the tin immersion mechanism 6 are electrically connected to the control module.

[0028] The tin loading mechanism 5 includes a tin melting furnace 51, a tin tank 52, a first electric push rod 53, a start switch 54, a filling block 55, a counterweight ball 56 and a distance sensor 57. Slot 52, the bottom of the tin...

Embodiment 2

[0034] On the basis of Example 1, such as figure 1 and image 3 As shown, it also includes a surplus material dumping mechanism 7, and the surplus material dumping mechanism 7 includes a toothed plate 71, a guide sleeve 72, a guide rod 73, a spring 74, a cross bar 75, a ratchet 76 and a shrapnel 77, and the first electric push rod 53 The right side of the expansion rod is connected with a tooth plate 71 by bolts, and a guide sleeve 72 is installed on the upper left side of the base 1, and a guide rod 73 is slidably arranged in the guide sleeve 72, and a cross bar 75 is welded on the top of the guide rod 73, and a cross bar 75 A spring 74 is connected between the guide sleeve 72, the spring 74 is wound on the guide rod 73, the left end of the cross bar 75 is hingedly connected with a pawl 76, the pawl 76 cooperates with the tooth plate 71, and the pawl 76 and the cross bar 75 are connected There are shrapnel 77.

[0035] Also includes a filter mechanism 8, the filter mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com