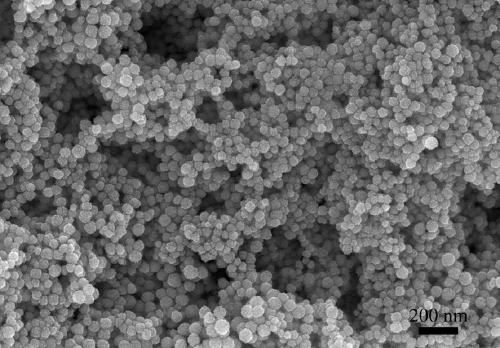

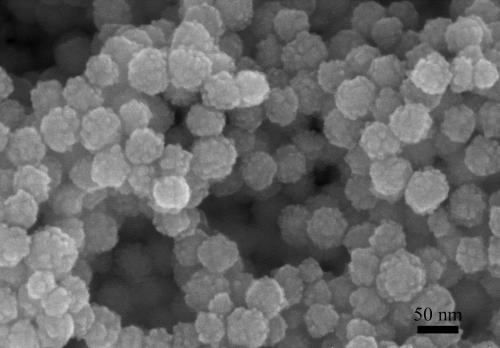

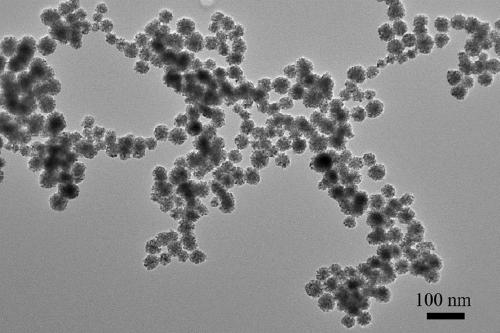

Self-supporting AuPd alloy mesoporous nanosphere and preparation method and application thereof

A nano-sphere, self-supporting technology, applied in chemical instruments and methods, non-metallic elements, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effect of enhancing catalytic activity, not easy to dissolve, and convenient for recovery and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing self-supporting AuPd alloy mesoporous nanospheres, comprising the following steps:

[0035] Step 1. Weigh a certain mass of polyionic liquid 1-butyl-3-methylimidazole polystyrene sulfonate and add it to water to prepare a reaction medium solution with a mass concentration of 0.0005-0.005 g / mL for later use;

[0036] Step 2, take 5 mL of the reaction medium solution in step 1 and add it to the reaction flask;

[0037] Step 3: Take 0.0005-0.005 mmol of HAuCl 4 Add into water to make HAuCl 4 solution, after which the prepared HAuCl 4 Solution is added in the reaction medium solution of step 2;

[0038] Step 4, take 0.0005-0.005 mmol of Na 2 PdCl 4 Added into water, prepared as Na 2 PdCl 4 solution, after which the prepared Na 2 PdCl 4 The solution is added to the mixed solution of step 3;

[0039] Step 5, taking vitamin C by weighing, adding it to distilled water, preparing a reducing agent vitamin C solution with a molar concentration of 0...

Embodiment 1

[0043] 1) Weigh 0.1 g of 1-butyl-3-methylimidazole polystyrene sulfonate, dilute to 100 mL, and prepare 1-butyl-3-methyl-imidazole with a mass concentration of 0.001 g / mL Polystyrene sulfonate polyionic liquid aqueous solution, which is the reaction medium solution, is for subsequent use;

[0044] 2) Take 5 mL of the reaction medium solution in step 1) into a round bottom flask;

[0045] 3) Add 0.001 mmol of HAuCl to the reaction medium solution in step 2) 4 solution;

[0046] 4) To the step 3) reaction solution, add the substance in an amount of 0.003 mmol of Na 2 PdCl 4 solution;

[0047] 5) Weigh vitamin C, add distilled water to prepare a vitamin C reducing agent aqueous solution with a molar concentration of 0.1 mol / L, and add 0.5 mL to the reaction solution in step 4);

[0048] Step 6) Gently shake the reaction bottle to mix the reaction solution evenly, and leave to react at room temperature for 2 h to prepare the reaction mixture;

[0049] 7) Centrifuge the react...

Embodiment 2

[0052] 1) Weigh 0.2 g of 1-butyl-3-methylimidazole polystyrene sulfonate, dilute to 100 mL, and prepare 1-butyl-3-methyl-imidazole with a mass concentration of 0.002 g / mL The aqueous solution of polystyrene sulfonate polyionic liquid is the reaction medium solution, which is ready for use;

[0053] 2) Take 5 mL of the reaction medium solution in step 1) into a round bottom flask;

[0054] 3) Add 0.001 mmol of HAuCl to the reaction medium solution in step 2) 4 aqueous solution;

[0055] 4) To the step 3) reaction solution, add the substance in an amount of 0.005 mmol of Na 2 PdCl 4 aqueous solution;

[0056] 5) Weigh vitamin C, add distilled water to prepare a vitamin C reducing agent aqueous solution with a molar concentration of 0.1 mol / L, and add 0.5 mL to the reaction solution in step 4);

[0057] Step 6) Gently shake the reaction bottle to mix the reaction solution evenly, and leave to react at room temperature for 2 h to prepare the reaction mixture;

[0058] 7) Cen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com