A preparation method of solid electrolyte with surface coating and solid electrolyte battery

A solid-state electrolyte and surface coating technology, applied in electrolytes, secondary batteries, circuits, etc., can solve the problems of not achieving high lithium ion conductivity, and achieve the effect of ensuring lithium ion conductivity and improving interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

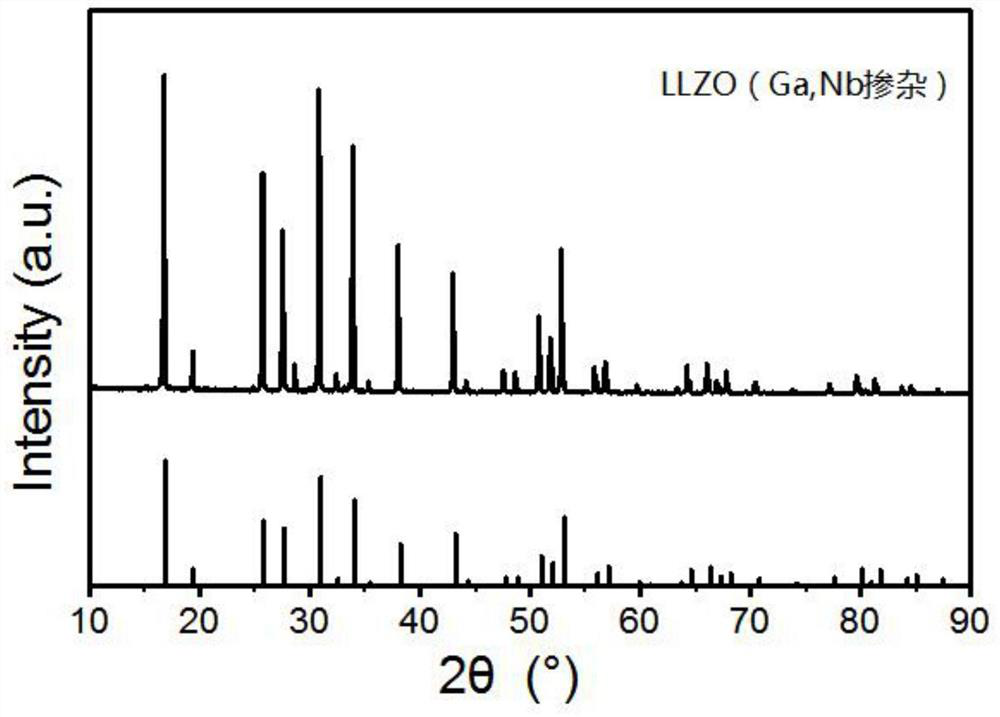

[0030] The target product of the inorganic ceramic sheet of the present embodiment is Li 6.35 Ga 0.15 La 3 Zr 1.8 Nb 0.2 o 12 .

[0031] The method for preparing a solid electrolyte with a surface coating in this embodiment includes the following steps:

[0032] S1, preparation of LLZO ceramic sheet: weigh Li respectively according to the stoichiometric ratio of the molecular formula (ie 6.35:3:1.8:0.2:0.15) 2 CO 3 , La 2 o 3 , ZrO 2 , Nb 2 o 5 and Ga 2 o 3 , the number of moles can be selected according to the size of the ball milling jar (0.02-0.1mol can be milled in a 1L ball milling jar). Among them, Li 2 CO 3 Excessive 5-20%. After the 5 kinds of raw materials are poured into the ball milling tank, isopropanol and ball milling beads are added for the first ball milling. The rotational speed of the first ball mill is 200-300rpm, and the time is 12-36h. After the first ball milling is completed, the solvent is dried to obtain a white powder (ie, the precu...

Embodiment 2

[0042] The steps of the preparation method of the solid electrolyte with surface coating in this embodiment are basically the same as the steps in Example 1, the difference is: (1) in step S4 of this embodiment, the lithium ion electrolyte and fumed silica The mixing is carried out in a beaker; (2) in step S5 of this embodiment, the prepared LLZO ceramic sheet is soaked in the above-mentioned FS glue solution.

[0043] In this embodiment, the lithium ion electrolyte solution (EC:DEC=1:1, LiPF6=1mol / L) and FS are mixed in a beaker according to the mass ratio of 20 to 50:1, and then stirred evenly with a magnet to form a transparent and Slightly viscous liquid.

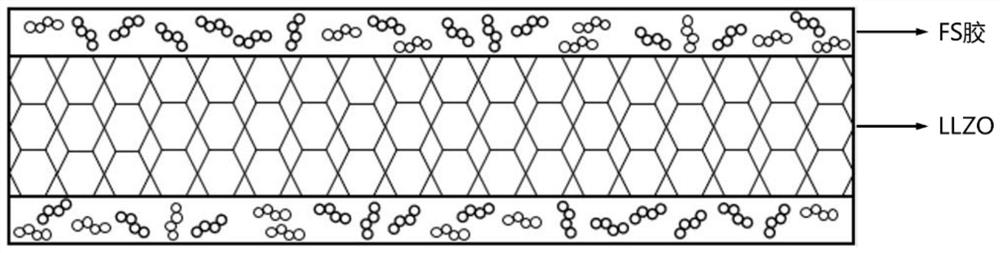

[0044] Soak the obtained LLZO ceramic sheet in the above solution for 1 to 10 minutes, and clamp it out to obtain a solid electrolyte with an FS adhesive layer. The structure of the solid electrolyte with a surface coating is as follows: Figure 5 shown.

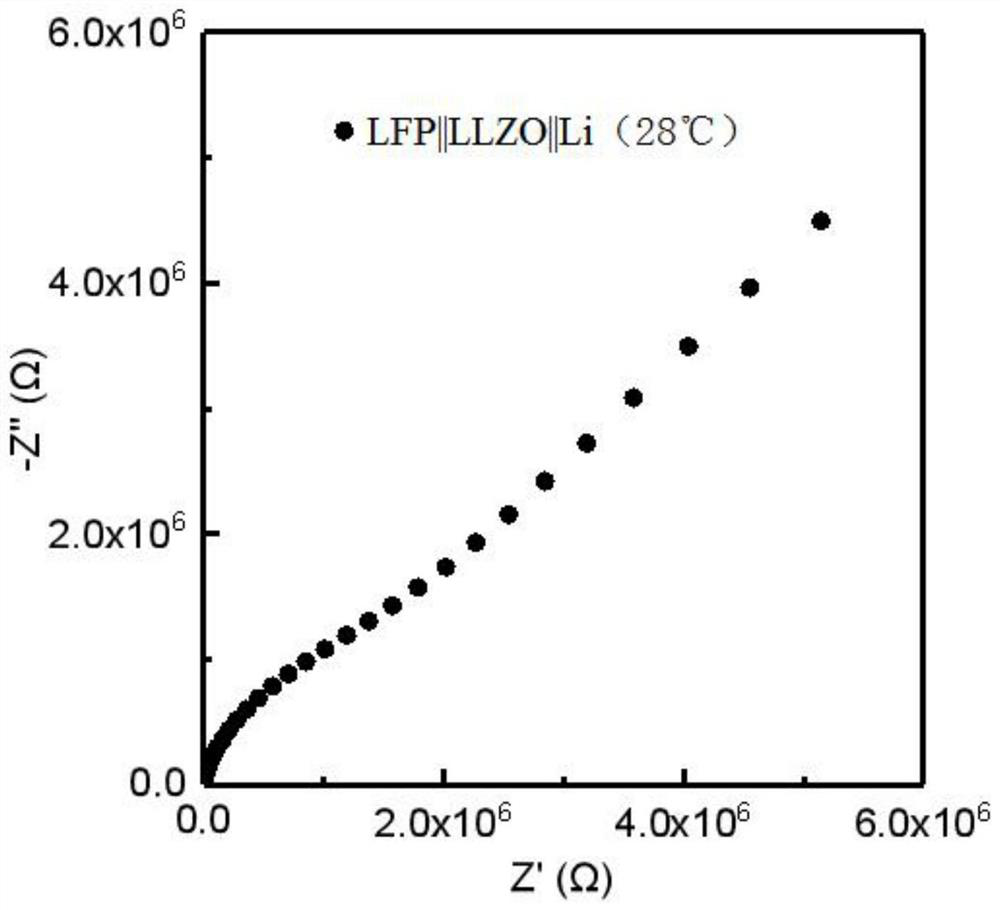

[0045] The invention provides a method for preparing a solid-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com