Method for producing high-quality gasoline by catalyzing diesel oil hydro-conversion

A technology for catalytic diesel and hydrogenation conversion, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment products, petroleum industry, etc. It can solve the problems that the product cannot reach the standard for a long time without considering it, the adjustment time is long, low, and not reached, etc., and achieves The effect of balancing activity, reducing start-up time and saving start-up cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

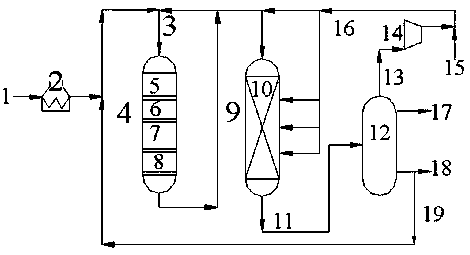

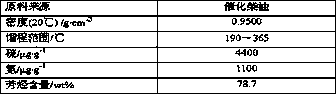

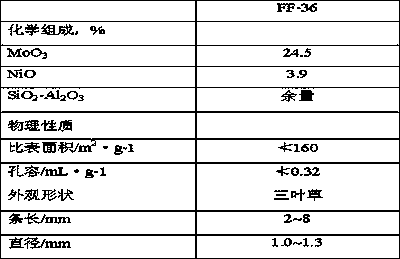

[0030] Embodiment 1~4 all adopts the method of the present invention, figure 1 The process flow shown. High-aromatic catalytic diesel is heated by a heating furnace and mixed with circulating hydrogen into the hydrofining reaction zone for reaction. The hydrofinishing reaction zone is equipped with four catalyst beds that are graded and filled with four kinds of FF-36 hydrogenation catalysts with different degrees of sulfidation. Examples 1-2 The degree of sulfidation of the catalyst in the first bed is ~80%, and the degrees of sulfidation of the catalysts in the second, third and fourth beds decrease by 10% one by one. Example 3 The degree of sulfurization of the catalyst in the first bed layer is ~75%, and the degrees of sulfurization of the catalysts in the second bed layer, the third bed layer, and the fourth bed layer are decreased by 10% one by one. Example 4 The degree of sulfurization of the catalyst in the first bed layer is ~70%, and the degrees of sulfurization of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com