Water-glycol type heat transfer medium with corrosion inhibition effect on galvanized pipe

A heat conduction, galvanized pipe technology, applied in the field of water-glycol type heat conduction medium, can solve the problems of zinc corrosion inhibition, corrosion, corrosion and other problems, achieve significant zinc corrosion inhibition performance, improve corrosion inhibition protection ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

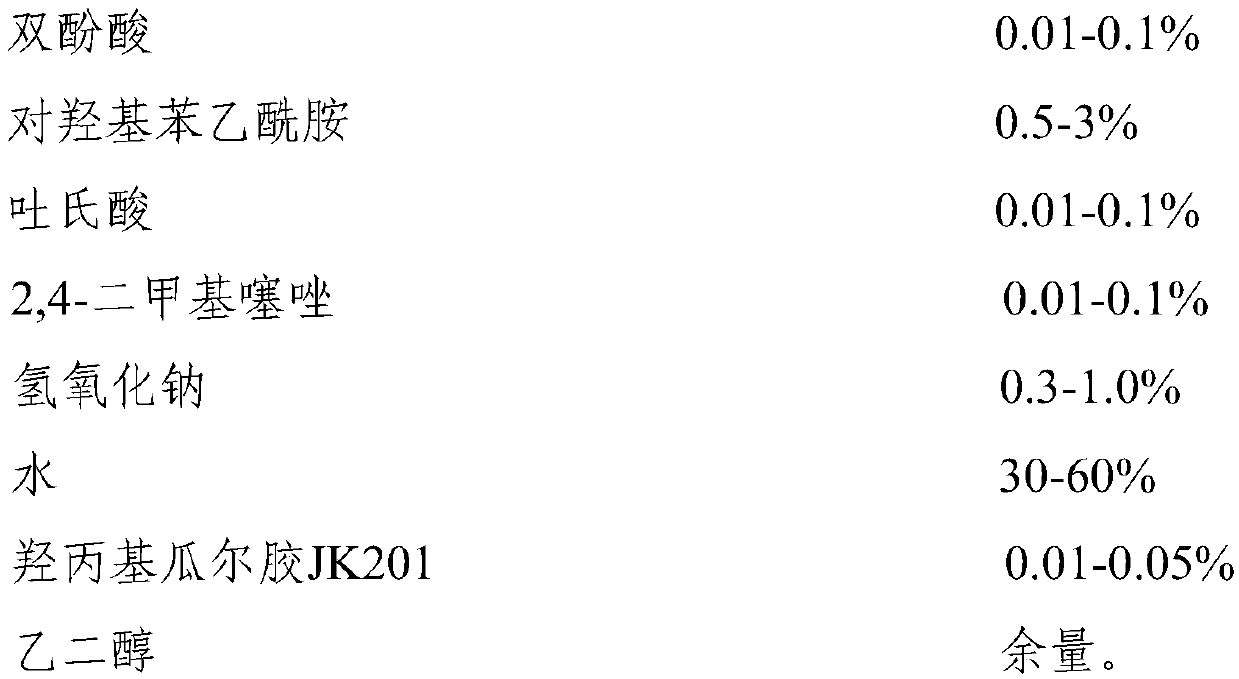

[0029] A kind of heat conduction medium that has corrosion inhibition effect on galvanized pipe, the formula is as follows (weight percentage):

[0030]

Embodiment 2

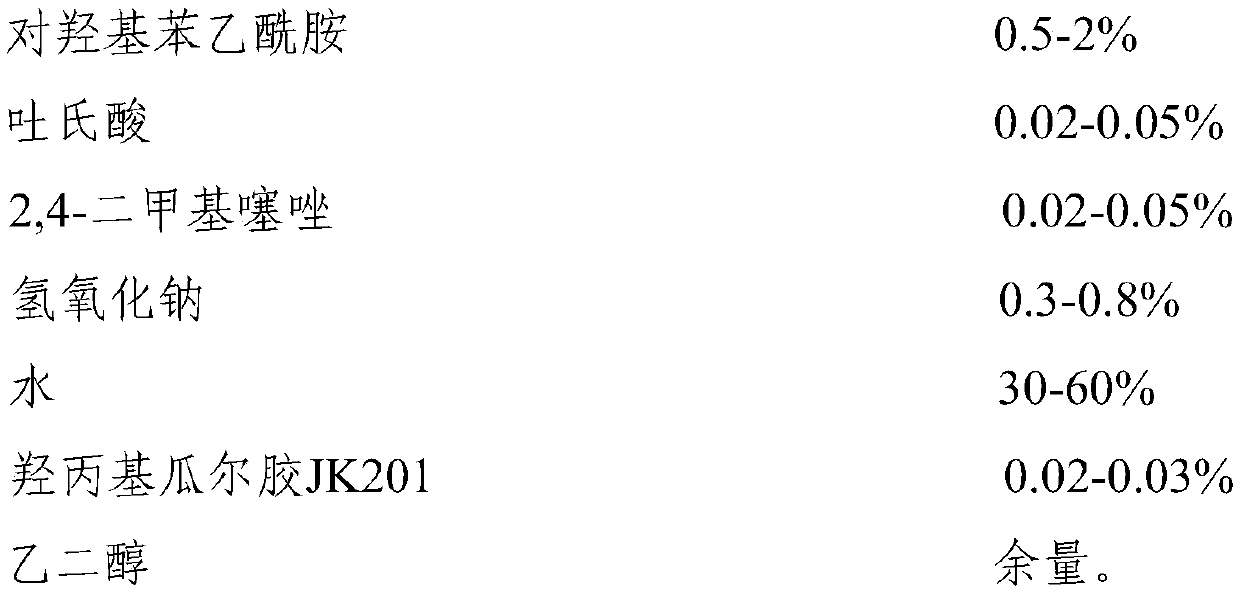

[0032] A kind of heat conduction medium that has corrosion inhibition effect on galvanized pipe, the formula is as follows (weight percentage):

[0033]

[0034]

Embodiment 3

[0036] A kind of heat conduction medium that has corrosion inhibition effect on galvanized pipe, the formula is as follows (weight percentage):

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com