Low-odor functional talc master batch and preparation method thereof

A low-odor, functional technology, applied in the field of automotive interior materials, can solve the problem of increasing material odor, and achieve the effect of reducing material shrinkage, reducing volatilization, and reducing emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

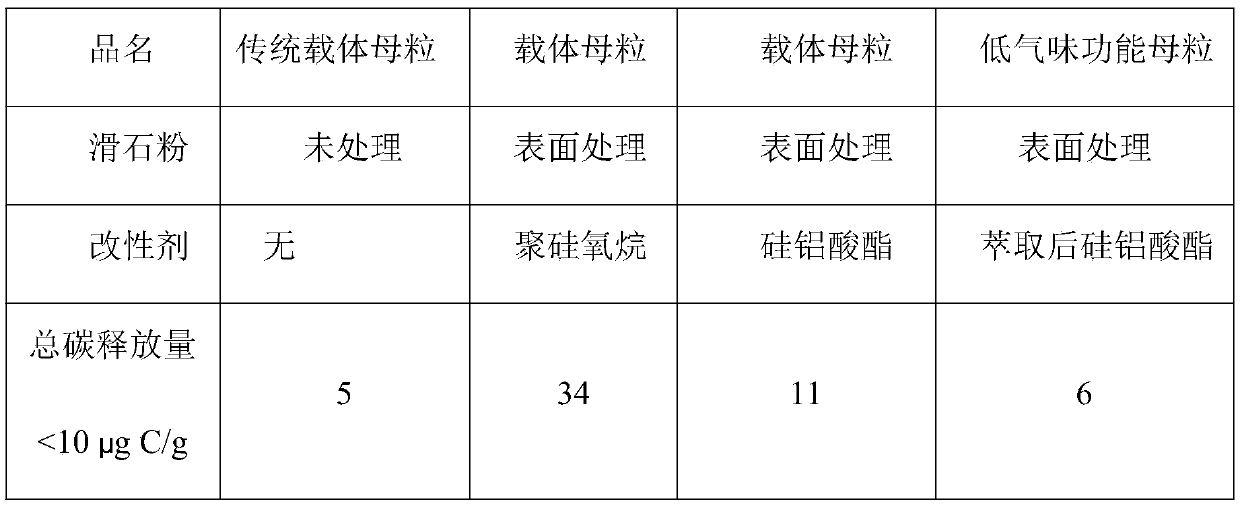

[0024] A low-odor functional talc master batch, comprising the following raw materials in parts by weight: 78 parts of talc powder, 0.8 parts of coupling agent, 20 parts of polypropylene monomer, 0.5 part of lubricant and 0.2 part of antioxidant. The coupling agent adopts aluminosilicate coupling agent, and the talc powder adopts flake talc powder. The diameter of the talc powder whose mass fraction is more than 50% in the talc powder is 6-8 μm.

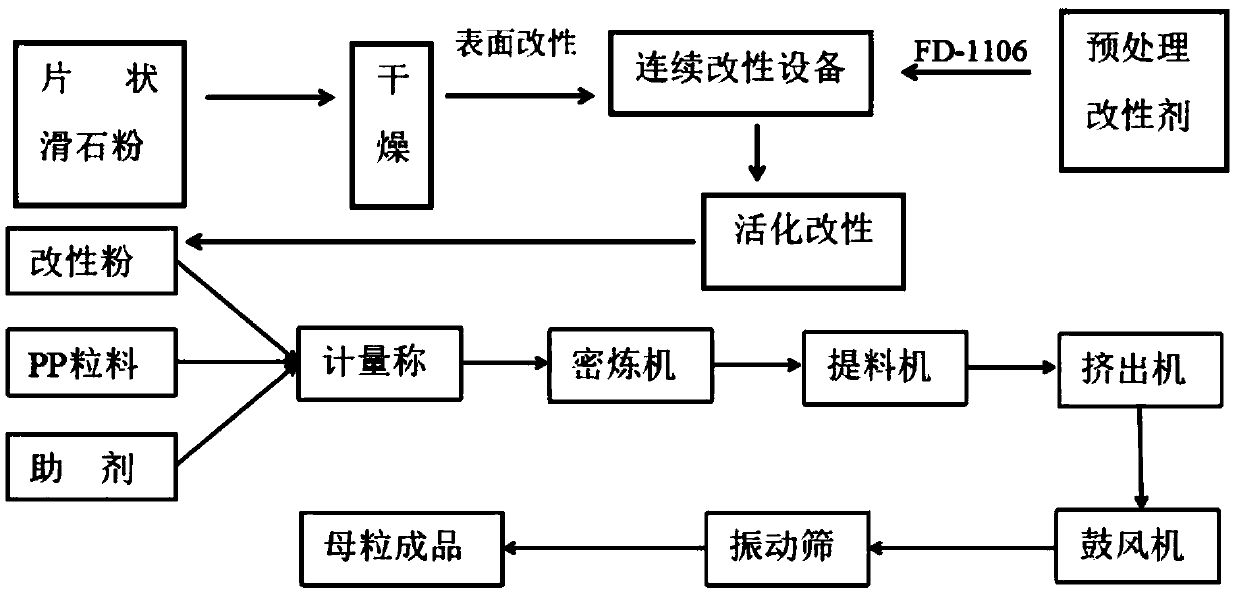

[0025] The preparation method of described low-odor functional talc masterbatch, concrete steps are as follows:

[0026] Step 1, extract the coupling agent, and then put it into the atomization chamber of the continuous modification equipment;

[0027] Step 2: put the talc powder into the continuous modification equipment and dry it at 85 degrees Celsius, and add the extracted coupling agent into the talc powder three times at a speed of 750rpm with a high-pressure spray system, with an interval of 3 minutes between each time, and m...

Embodiment 2

[0029] A low-odor functional talc masterbatch, comprising the following raw materials in parts by weight: 79 parts of talc powder, 0.9 part of coupling agent, 21 parts of polypropylene monomer, 0.66 part of lubricant and 0.34 part of antioxidant. The specification of polypropylene is 511MK-40T, the specification of lubricant is EBS, and the antioxidant is antioxidant 168.

[0030] The preparation method of described low-odor functional talc masterbatch, concrete steps are as follows:

[0031] Step 1, extract the coupling agent, and then put it into the atomization chamber of the continuous modification equipment;

[0032] Step 2: Put the talcum powder into the continuous modification equipment and dry it at 88 degrees Celsius. Add the extracted coupling agent to the talcum powder three times at a low speed with a high-pressure spray system, with an interval of 4 minutes between each time. Continue to react for 28 minutes under the rotating speed to obtain modified talcum powd...

Embodiment 3

[0035] A low-odor functional talc master batch, comprising the following raw materials in parts by weight: 80 parts of talc powder, 1 part of coupling agent, 22 parts of polypropylene monomer, 0.8 part of lubricant and 0.5 part of antioxidant. The coupling agent adopts aluminosilicate coupling agent whose specification is FD-1106, and the talc powder adopts flake talc powder. The specification of polypropylene is 511MK-40T, the specification of lubricant is EBS, and the antioxidant is antioxidant 168. The diameter of the talc powder whose mass fraction is more than 50% in the talc powder is 6-8 μm.

[0036] The preparation method of described low-odor functional talc masterbatch, concrete steps are as follows:

[0037] Step 1, extract the coupling agent, and then put it into the atomization chamber of the continuous modification equipment;

[0038] Step 2: Put the talcum powder into the continuous modification equipment and dry it at 86 degrees Celsius. Add the extracted cou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com