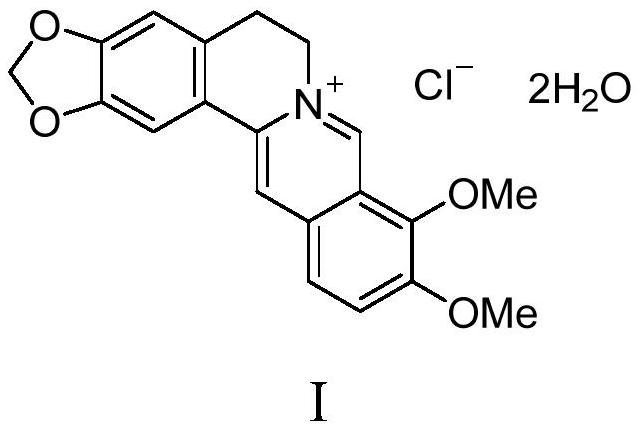

Purification method of berberine or its hydrochloride

A purification method and technology of berberine, which is applied in the field of purification of berberine or its hydrochloride, can solve the problems of failure to meet standards, low efficiency, low success rate, etc., and achieve the effects of mild reaction conditions, simple and convenient operation, and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

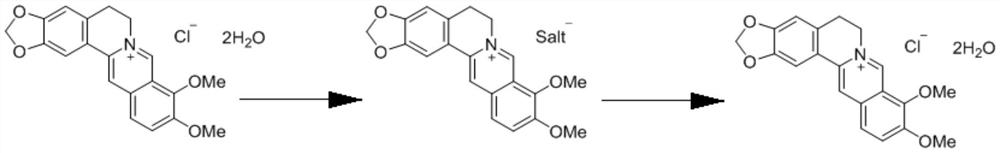

[0035] Embodiment 1: acesulfame potassium salt method

[0036] 9.09 grams of berberine hydrochloride (purity 95%) was heated to 80 degrees and dissolved in 75 milliliters of water, and stirred for 30 minutes to obtain an orange solution. At the same time, 5.44 grams of acesulfame potassium was dissolved in water and added to the above solution, stirred for 10 minutes, and precipitates were precipitated, cooled to 25 degrees, and continued to stir and crystallize for 16 hours. Filter, the filtered solid is suspended in 30 ml of water, add 1N HCl aqueous solution (27 mmol), stir and heat up to 90 degrees, after 2 hours, cool down to about 10 degrees, continue stirring for 2 hours, filter and dry to obtain 8.5 grams of berberine hydrochloride . The purity is 99.85%, and the impurity content is less than 0.1%.

[0037] The NMR data of berberine hydrochloride are as follows:

[0038] 1 H-NMR, CD 3 OD, 400MHZ, δ3.28-3.31[m,2H], δ4.12[s,3H], δ4.23[s,3H], δ4.97-4.99[m,2H], δ6.14[...

Embodiment 2

[0039] Embodiment 2: saccharin sodium salt method

[0040] Add 14.88g of berberine hydrochloride (purity 96%) and 800ml of water to a 2L four-necked bottle at room temperature, heat up to 75°C to dissolve and keep stirring for 30min, then add 10.68g of saccharin sodium solution (dissolved in 200ml of water) dropwise, and there are crystals Precipitate, keep warm for half an hour after adding, then drop to room temperature and keep stirring overnight, then filter to obtain berberine saccharin salt. Add 600ml of water to the berberine saccharin salt, slowly add 44ml of 1mol / L hydrochloric acid dropwise at room temperature, heat and stir for 1.5 hours after the addition, then raise the temperature to 80°C and stir for 2 hours, then cool down to room temperature and stir for 2 hours, then filter to obtain berberine hydrochloride , the yield was 89%. The purity is 99.85%, and the impurity content is less than 0.1%.

Embodiment 3

[0041] Embodiment 3: acesulfame potassium salt method

[0042] 9.09 g of berberine hydrochloride (purity 90%) was heated to 75°C and dissolved in 75 ml of water, and stirred for 30 minutes to obtain an orange solution. At the same time, 8.10 grams of acesulfame potassium was dissolved in water and added to the above solution, stirred for 10 minutes, and precipitates were precipitated, cooled to 25 degrees, and continued to stir and crystallize for 16 hours. Filter, the filtered solid is suspended in 30 ml of water, add 1N HCl aqueous solution (27mmol), stir and heat up to 80°C, after 2 hours, cool down to about 10°C, continue stirring for 2h, filter and dry to obtain 8.7g of berberine hydrochloride . The purity is 99.85%, and the impurity content is less than 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com