A dyeing and processing method of a pencil board of a colored wood hole pen and the colored wood hole pen

A processing method and pencil board technology, which is applied in wood processing equipment, manufacturing tools, wood treatment, etc., can solve the problem of difficulty in realizing irregular equivalent hole processing and production, inconsistent color penetration of pencil boards, and inconsistent color shades, etc. problem, to achieve the effect of bright colors, good softening and penetration effects, and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

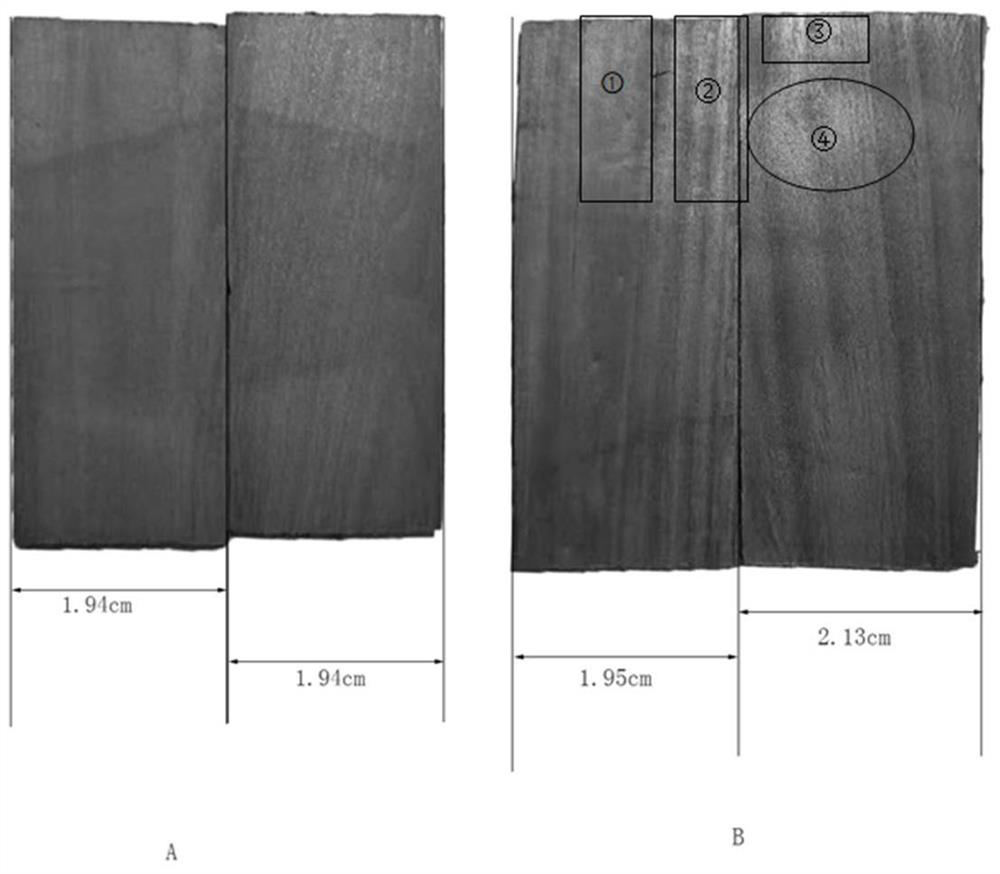

Image

Examples

Embodiment 1

[0035] Embodiment 1: For the pencil board made of poplar wood, the first color system takes wood bright red pigment as an example. The specific steps of dyeing and processing the pencil board are as follows:

[0036] ① Prepare the pigment for cork staining, that is, wood bright red pigment. The three color pigments in the present invention correspond to the Pantone color numbers in Table 1 below. The first color system includes wood rose red, wood bright yellow, wood orange, wood bright red; the second color system includes: wood green, wood dark blue, wood purple, wood black; the third color system includes: wood bright green, wood blue, Wood light brown, wood dark brown. Pigments can be purchased from the market or configured by yourself.

[0037] The 12 colors in the present invention correspond to the Pantone color numbers in the table below.

[0038] Table 1 - Correspondence between colors and Pantone color numbers

[0039]

[0040] ②Preparation of pencil board: ch...

Embodiment 2

[0044] Embodiment two: for the pencil board made of basswood, the second color system takes wood purple pigment as an example, and the specific steps of dyeing and processing the pencil board are as follows:

[0045] ① Prepare the pigment for cork staining, that is, wood purple pigment.

[0046] ②Preparation of pencil board: use basswood with a diameter of 45cm as the log; untie and cut off the log, after high-temperature steam treatment, cut it into pencil board by cutting machine, and manually select the pencil board with whiter surface;

[0047] ③Treat the pencil board: soften the wood board: a. Dry the pencil board to a moisture content of 15%; b. Put the dried pencil board into the impregnation tank.

[0048] Then, prepare the infusion solution: first put 45 kg of paraffin wax and 30 kg of emulsified wax into the batching container, continue to put in 7 kg of softener, 2 kg of penetrating agent, 1 kg of glacial acetic acid and 1000 kg of water, and then put in 50 kg of wo...

Embodiment 3

[0050] Embodiment three: for the pencil board made of basswood, the third color system takes wood blue pigment as an example, and the specific steps of dyeing and processing the pencil board are as follows:

[0051] ① Prepare the pigment for cork staining, that is, wood blue pigment.

[0052] ②Preparation of pencil board: use basswood with a diameter of 45cm as the log; untie and cut off the log, after high-temperature steam treatment, cut it into pencil board by cutting machine, and manually select the pencil board with whiter surface;

[0053] ③Treat the pencil board: soften the wood board: a. Dry the pencil board to a moisture content of 15%; b. Put the dried pencil board into the impregnation tank.

[0054] Then, prepare the infusion solution: first put 40 kg of paraffin wax and 25 kg of emulsified wax into the batching container, continue to put in 6 kg of softener, 2 kg of penetrating agent, 1 kg of glacial acetic acid and 1000 kg of water, and then put in 45 kg of wood ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com