Oil coating device for tin electroplating treatment

An oil coating device and electro-tinning technology are applied to the surface coating liquid device, coating, cleaning method and utensils, etc., which can solve the problems of missing coating of workpieces, affecting the service life of workpieces, waste of anti-rust oil, etc., and achieve The effect of reducing waste, improving efficiency, and simplifying oiling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

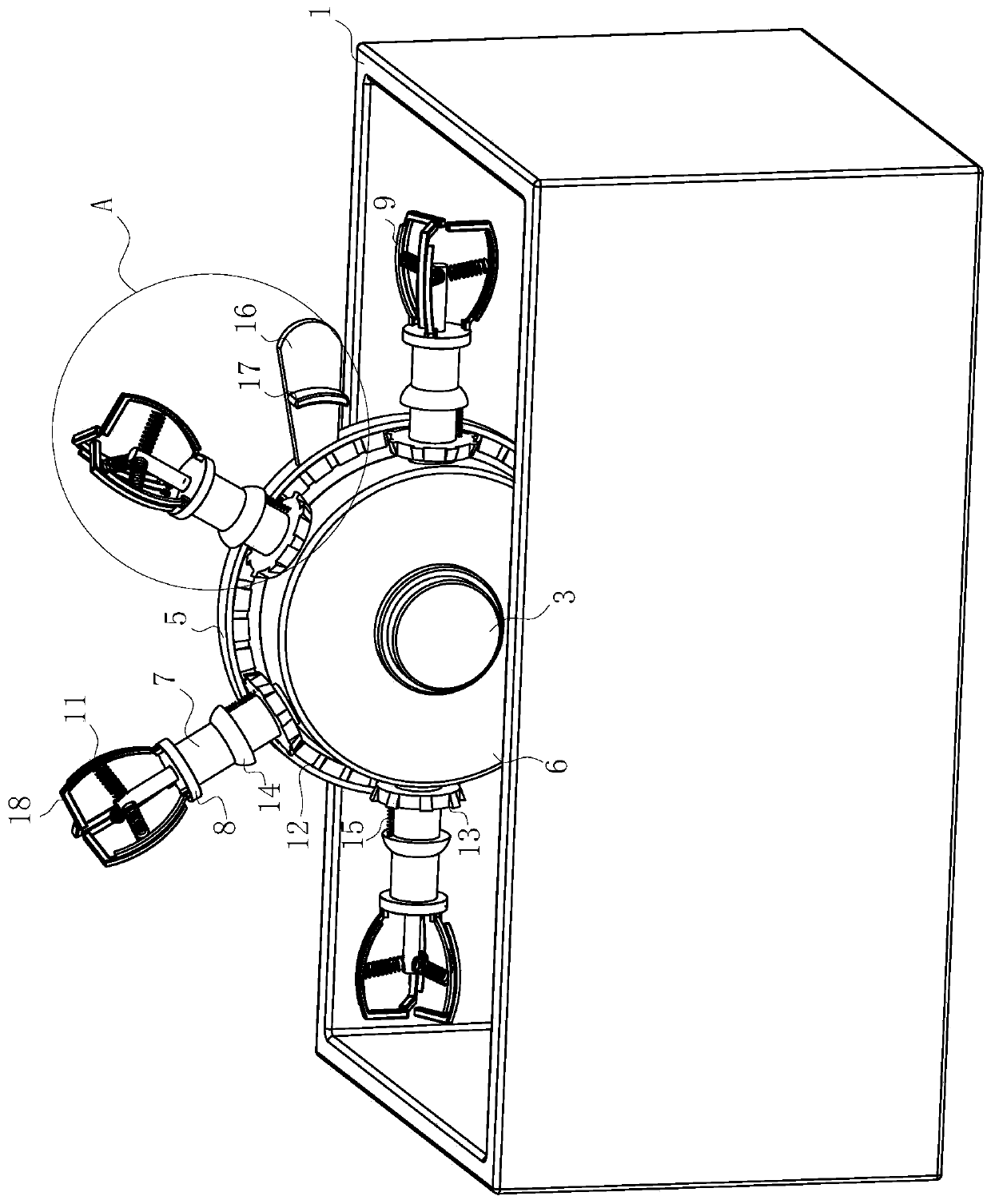

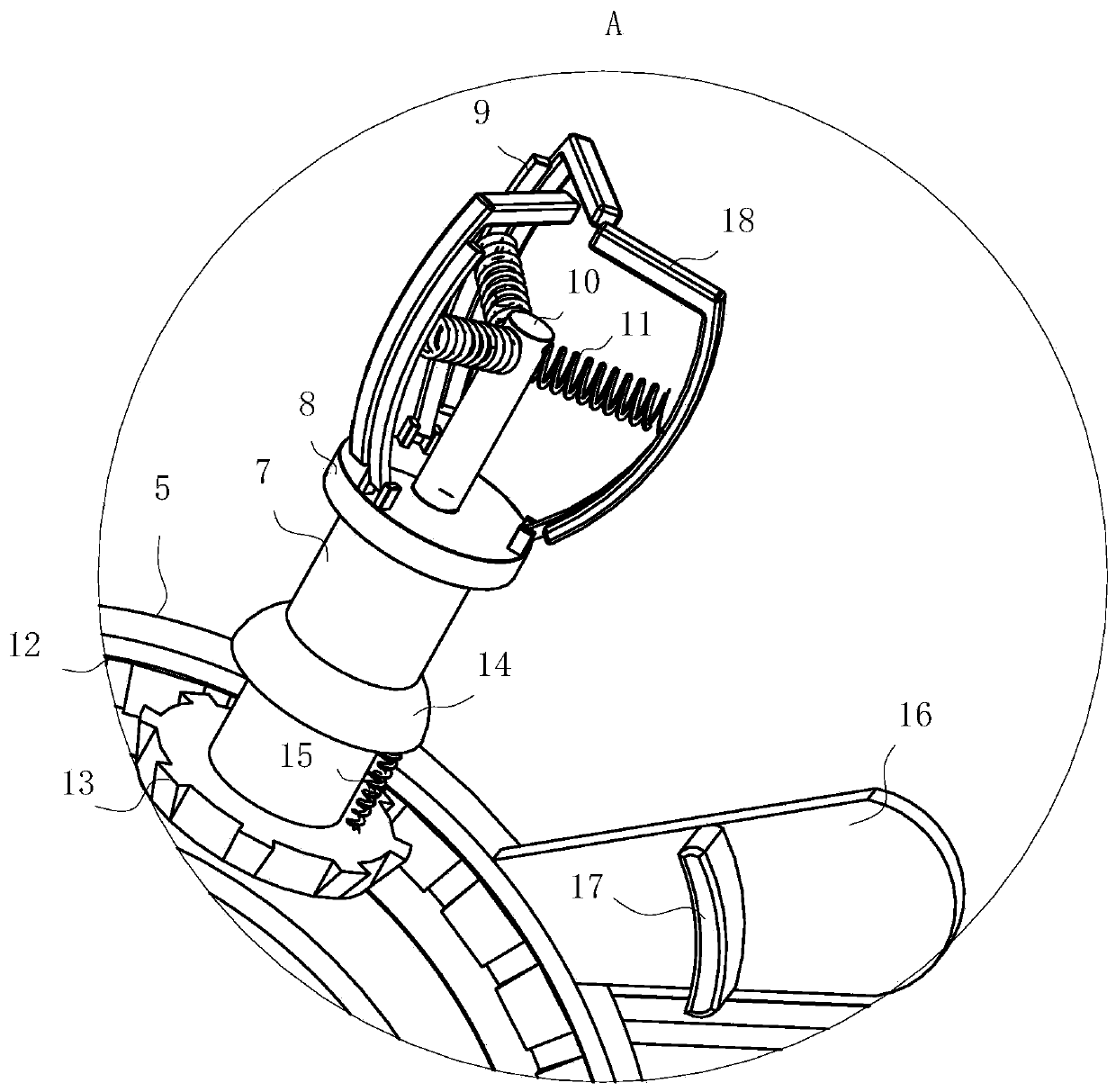

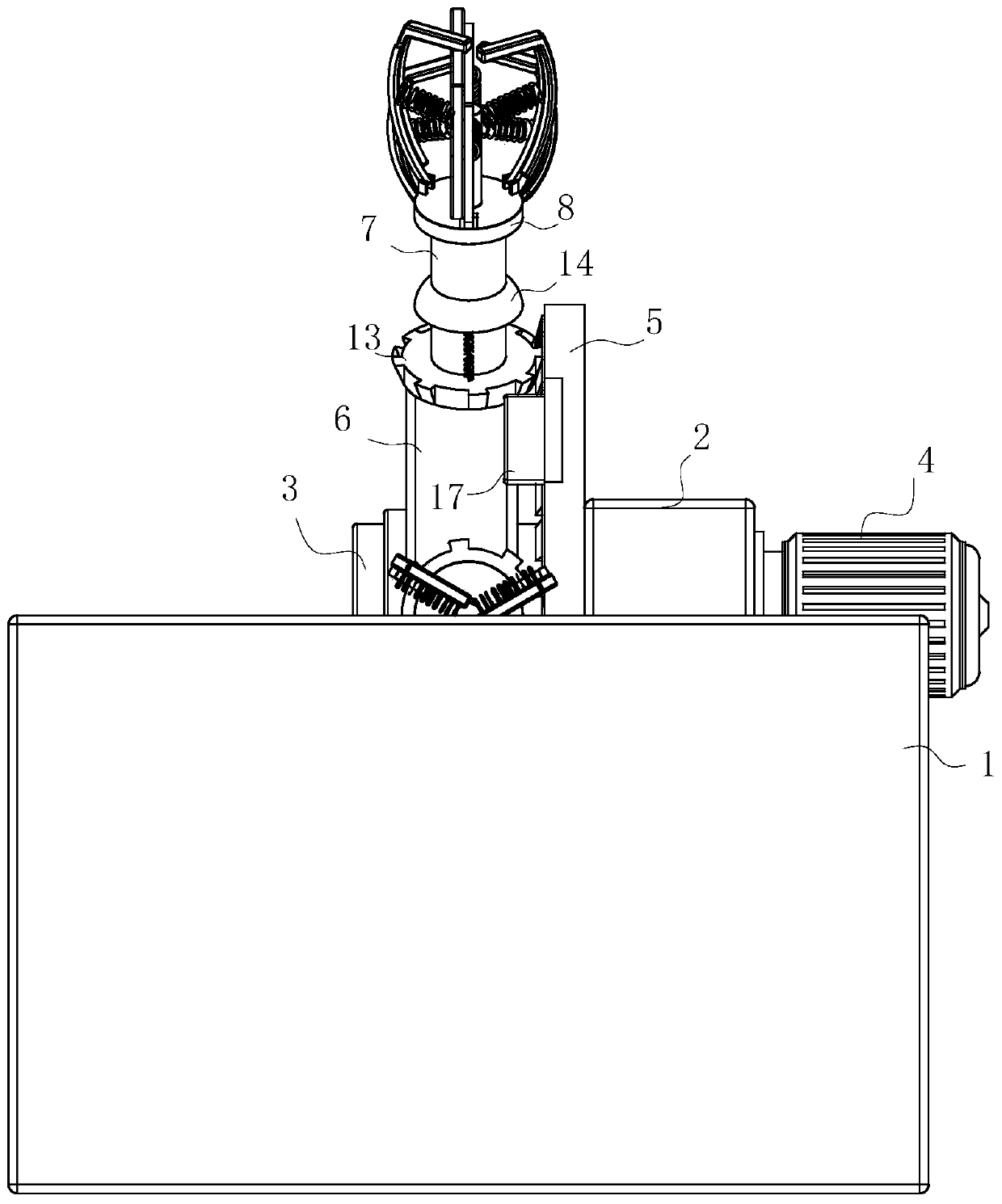

[0032] As a specific embodiment of the present invention, a No. 1 helical gear 12 is fixed on the side of the No. 1 plate 5 away from the drive motor 4, and a No. 2 helical gear 13 is fixed on the end of the connecting rod 7 close to the No. 2 disc 6. The No. 2 helical gear 13 meshes with the No. 1 helical gear 12. During work, the contact between the gripper 9 and the workpiece will easily cause the contact part of the workpiece and the gripper 9 to be difficult to contact the anti-rust oil, thereby causing the missing coating of the workpiece; The setting of the helical gear 12 and the second helical gear 13 makes the connecting rod 7 drive the second helical gear 13 to rotate during the rotation, so that the second helical gear 13 and the first helical gear 12 are relatively displaced; the rotating second helical gear The gear 13 rotates during the relative displacement with the No. 1 helical gear 12, so that the connecting rod 7 rotates, so that the gripper 9 rotates around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com