Lead storage battery formation process optimization method

A technology for lead-acid batteries and process optimization, which is applied in the direction of lead-acid batteries, lead-acid battery construction, secondary batteries, etc., can solve problems such as long production cycle, energy consumption, potential control method and time control method are not applicable, and achieve The effects of low energy consumption, high formation efficiency, and short formation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The battery model is 6-DZF-20 battery.

[0032] Before adding acid, drive the copper nails used as detection electrodes on the bus bar of each single cell, install the acid adding pot for lead storage battery to add acid, insert the reference electrode and temperature sensor (reference electrode and temperature sensor) into the acid adding pot The detection end of the sensor is immersed in the electrolyte), and the reference electrode is a mercurous sulfate electrode, and then chemically formed.

[0033] The optimization steps are as follows:

[0034] The first charge: 1.5A for 0.5h, 2A for 0.5h, 3A for 2h, 5A for 2h, 8A for 2h, the temperature reaches 45°C, 5A for 2h, and the negative potential reaches -1.40V.

[0035] The first discharge: 10A discharge to the positive potential to 0.95V, discharge 0.25h.

[0036] The second charging: 10A charging until the negative pole reaches -1.40V, charging time 0.2h; 6A charging 2h potential change is less than 15mV, charging t...

Embodiment 2

[0046] The battery model is 6-DZF-20 battery.

[0047] Before adding acid, drive the copper nails used as detection electrodes on the bus bar of each single cell, install the acid adding pot for lead storage battery to add acid, insert the reference electrode and temperature sensor (reference electrode and temperature sensor) into the acid adding pot The detection end of the sensor is immersed in the electrolyte), and the reference electrode is a mercurous sulfate electrode, and then chemically formed.

[0048] The optimization steps are as follows:

[0049] The first charge: 1.5A charging for 0.5h, 2A charging for 0.5h, 3A charging for 0.5h, 5A charging for 2h, 5A charging for 4.5h, the temperature reaches 45°C, 3.5A charging for 2.5h, and the negative electrode potential reaches -1.40V.

[0050] The first discharge: 10A discharge to the positive potential to 0.95V, discharge 0.25h.

[0051] The second charging: 7A charging until the negative electrode reaches -1.40V, charg...

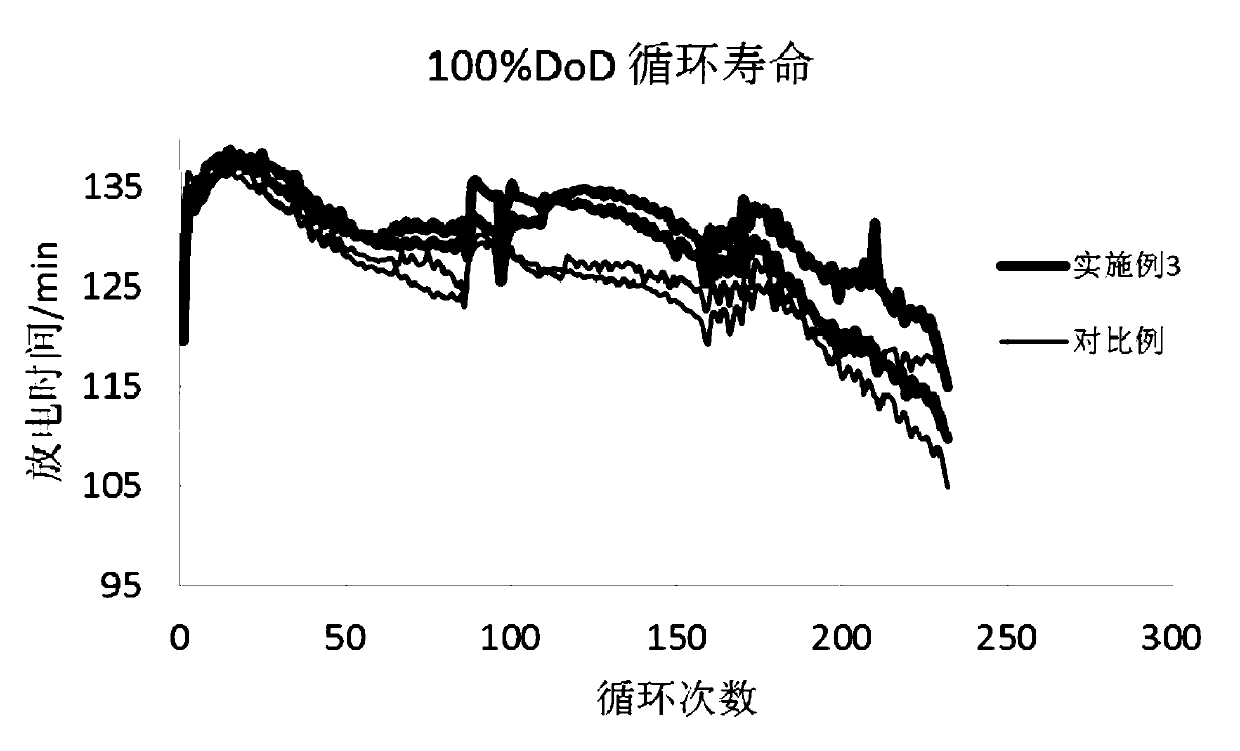

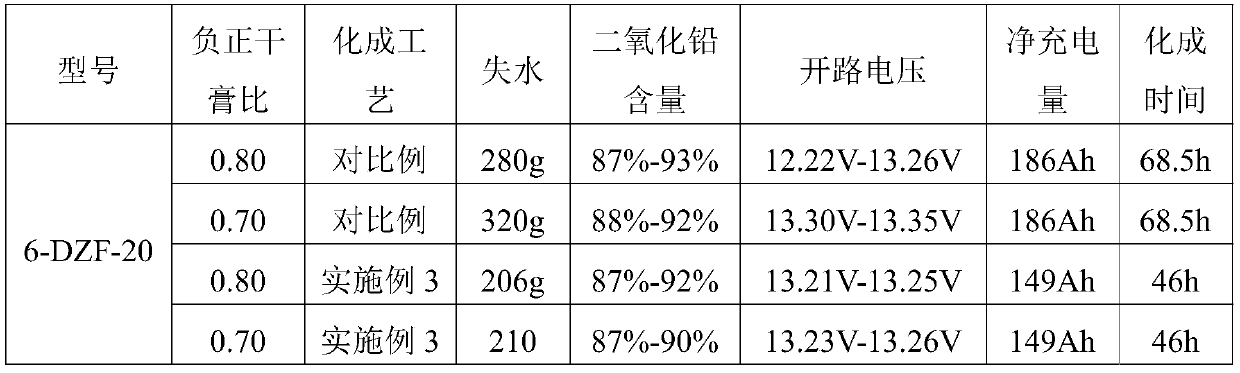

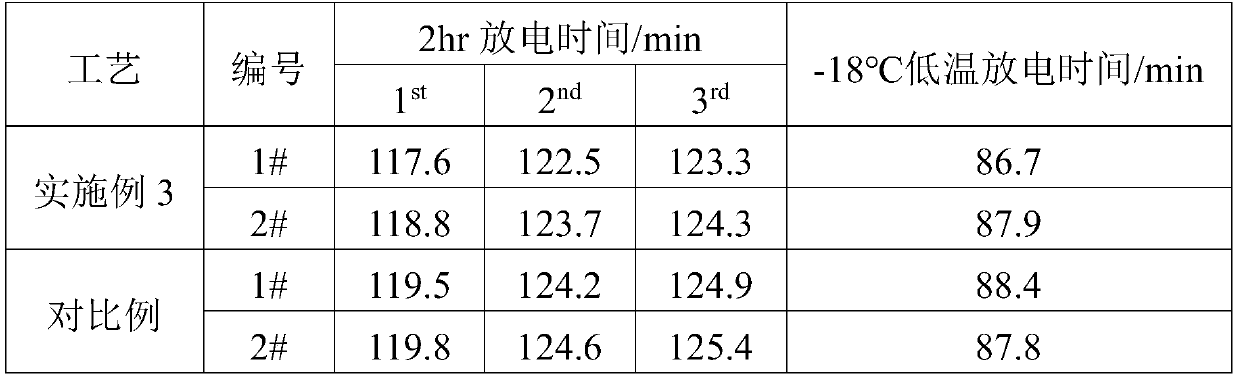

Embodiment 3

[0061] The battery model is 6-DZF-20 battery.

[0062] Before adding acid, drive the copper nails used as detection electrodes on the bus bar of each single cell, install the acid adding pot for lead storage battery to add acid, insert the reference electrode and temperature sensor (reference electrode and temperature sensor) into the acid adding pot The detection end of the sensor is immersed in the electrolyte), and the reference electrode is a mercurous sulfate electrode, and then chemically formed.

[0063] The optimization steps are as follows:

[0064] First charge: 1.5A charging for 0.5h, 2.5A charging for 0.5h, 3.5A charging for 0.5h, 4.5A charging for 1h, 5.5A charging for 4.5h, the temperature reaches 45°C, 4.5A charging for 3h, the negative potential reaches -1.40V .

[0065] The first discharge: 10A discharge to the positive potential to 0.95V, discharge 0.3h.

[0066] The second charging: 8A charging until the negative electrode reaches -1.40V, charging time 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com