Biochar-immobilized naphthalene-degrading microbial agent and preparation method and application thereof

A technology of naphthalene degrading bacteria and biochar, applied in chemical instruments and methods, fixed on or in inorganic carriers, fixed on/in organic carriers, etc., can solve the competition of soil indigenous microorganisms and the easy loss of free strains and other problems, to achieve good repair effect, broad engineering application prospects, and the effect of improving environmental concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a kind of preparation method of biochar-immobilized naphthalene-degrading bacterial agent, and concrete steps are as follows:

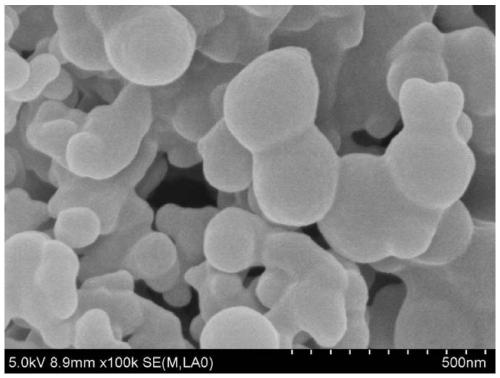

[0036] Step 1: Weigh 2g of microcrystalline cellulose and mix it with water in a polytetrafluoroethylene-lined tank, put it into a stainless steel reaction kettle, heat it to 280°C for 2 hours, cool at room temperature after the reaction, and solidify at 12000r / min Then, the solid product was repeatedly washed with distilled water and absolute ethanol, freeze-dried for 12 hours and ground to obtain biochar, which was named MCC280 (see figure 1 );

[0037] Step 2: Mix 0.1g of the frozen naphthalene-degrading strain and 2g of MCC280 biochar into 100mL of LB liquid medium, place in a constant temperature shaker for 12h, the temperature is 37°C, and the shaking rate is 150r / min, to obtain a uniform mixed bacterial solution;

[0038]Step 3: Mix the above-mentioned mixed bacterial solution with sodium alginate solution at a...

Embodiment 2

[0041] This embodiment provides a kind of preparation method of biochar-immobilized naphthalene-degrading bacterial agent, and concrete steps are as follows:

[0042] Step 1: Weigh 5g of microcrystalline cellulose and mix it with water in a polytetrafluoroethylene-lined tank, put it into a stainless steel reaction kettle, heat it to 220°C for 2 hours, cool at room temperature after the reaction, and solidify at 12000r / min Then, the solid product was repeatedly washed with distilled water and absolute ethanol, freeze-dried for 12 hours and ground to obtain biochar, which was named MCC220 (see image 3 );

[0043] Step 2: Mix 0.1g of the frozen naphthalene-degrading strain and 5g of MCC220 biochar into 100mL of LB liquid medium, place in a constant temperature shaker for 12h, the temperature is 37°C, and the shaking rate is 150r / min, to obtain a uniform mixed bacterial solution;

[0044] Step 3: Mix the above-mentioned mixed bacterial solution with sodium alginate solution at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com