Formula and preparation method of fully synthetic metal working fluid for improving lubricity

A metalworking fluid, fully synthetic technology, used in lubricating compositions, petroleum industry, etc., can solve the problems of limited metal adsorption, unable to form a lubricating film, easy to be washed away by water, etc., to achieve excellent cooling and lubrication, ensure lubrication effect, effect of good lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

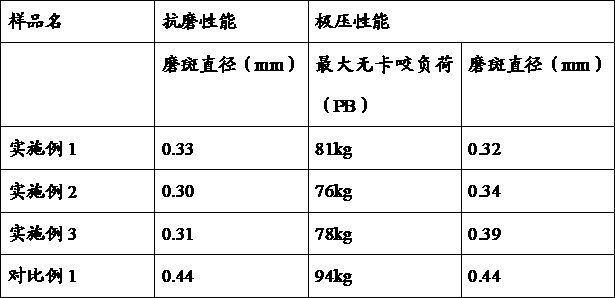

Examples

Embodiment 1

[0034] A fully synthetic metalworking fluid formula that improves lubricity, including: hyaluronic acid, RPE 1720, RPE1740, isononanoic acid, monoethanolamine, triethanolamine and water, by weight percentage as follows:

[0035] Hyaluronic Acid 0.1%

[0036] RPE 1720 2.5%

[0037] RPE1740 2.5%

[0038] Isononanoic Acid 3%

[0039] Monoethanolamine 3%

[0040] Triethanolamine 5%

[0041] water balance

[0042] The preparation method is as follows:

[0043] A. Add 0.1% hyaluronic acid and water in the reactor;

[0044] B. After heating at 50°C, carry out mechanical + pulse stirring, and the stirring time is 3 hours;

[0045] C. Add RPE 1720 2.5%, RPE 1740 2.5%, isononanoic acid 3%, monoethanolamine 3% and triethanolamine 5% in the stirring device

[0046] D. Filtration;

[0047] E. Detection;

[0048] F, feeding.

[0049] Inspection work includes appearance, stability, rust resistance, water-soluble acid or alkali, and corrosion inspection. There are a lot of carboxy...

Embodiment 2

[0051] A fully synthetic metalworking fluid formula that improves lubricity, including: hyaluronic acid, RPE 1720, RPE1740, isononanoic acid, monoethanolamine, triethanolamine and water, by weight percentage as follows:

[0052] Hyaluronic Acid 0.12%

[0053] RPE 1720 5%

[0054] RPE1740 5%

[0055] Isononanoic Acid 3%

[0056] Monoethanolamine 3%

[0057] Triethanolamine 5%

[0058] water balance

[0059] The preparation method is as follows:

[0060] A. Add 0.12% hyaluronic acid and water in the reactor;

[0061] B. After heating at 60°C, carry out mechanical + pulse stirring;

[0062] C. Add RPE 1720 5%, RPE 1740 5%, isononanoic acid 3%, monoethanolamine 3% and triethanolamine 5% in the stirring device

[0063] D. Filtration;

[0064] E. Detection;

[0065] F, feeding.

[0066]Inspection work includes appearance, stability, rust resistance, water-soluble acid or alkali, and corrosion inspection. There are a lot of carboxyl groups and carbonyl groups in the hyalu...

Embodiment 3

[0068] A fully synthetic metalworking fluid formula that improves lubricity, including: hyaluronic acid, RPE 1720, RPE1740, isononanoic acid, monoethanolamine, triethanolamine and water, by weight percentage as follows:

[0069] Hyaluronic Acid 1%

[0070] RPE 1720 4%

[0071] RPE1740 4%

[0072] Isononanoic Acid 3%

[0073] Monoethanolamine 3%

[0074] Triethanolamine 5%

[0075] water balance

[0076] The preparation method is as follows:

[0077] A. Add 1% hyaluronic acid and water in the reactor;

[0078] B. After heating at 70°C, carry out mechanical + pulse stirring;

[0079] C. Add RPE 1720 4%, RPE 1740 4%, isononanoic acid 3%, monoethanolamine 3% and triethanolamine 5% in the stirring device

[0080] D. Filtration;

[0081] E. Detection;

[0082] F, feeding.

[0083] Inspection work includes appearance, stability, rust resistance, water-soluble acid or alkali, and corrosion inspection. There are a lot of carboxyl groups and carbonyl groups in the hyaluronic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com