Explosive-proof and intrinsic safety type hazardous gas routing inspection robot

A technology for inspection robots and dangerous gases, applied in the field of robots, can solve the problems of difficult carrying equipment, strong subjective awareness, different numerical parameters, etc., to facilitate manual remote control and data analysis, avoid inconvenience and risks, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

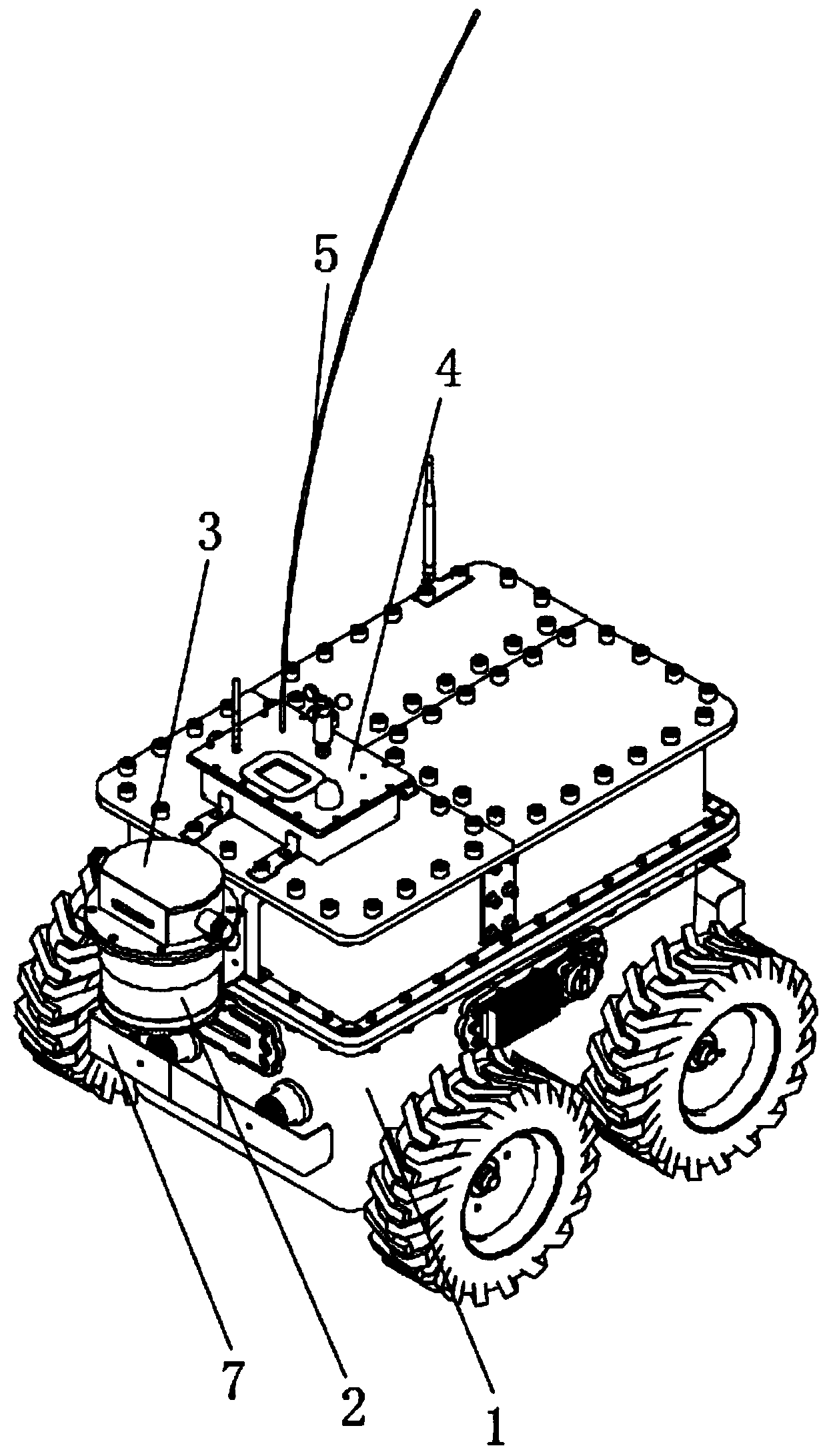

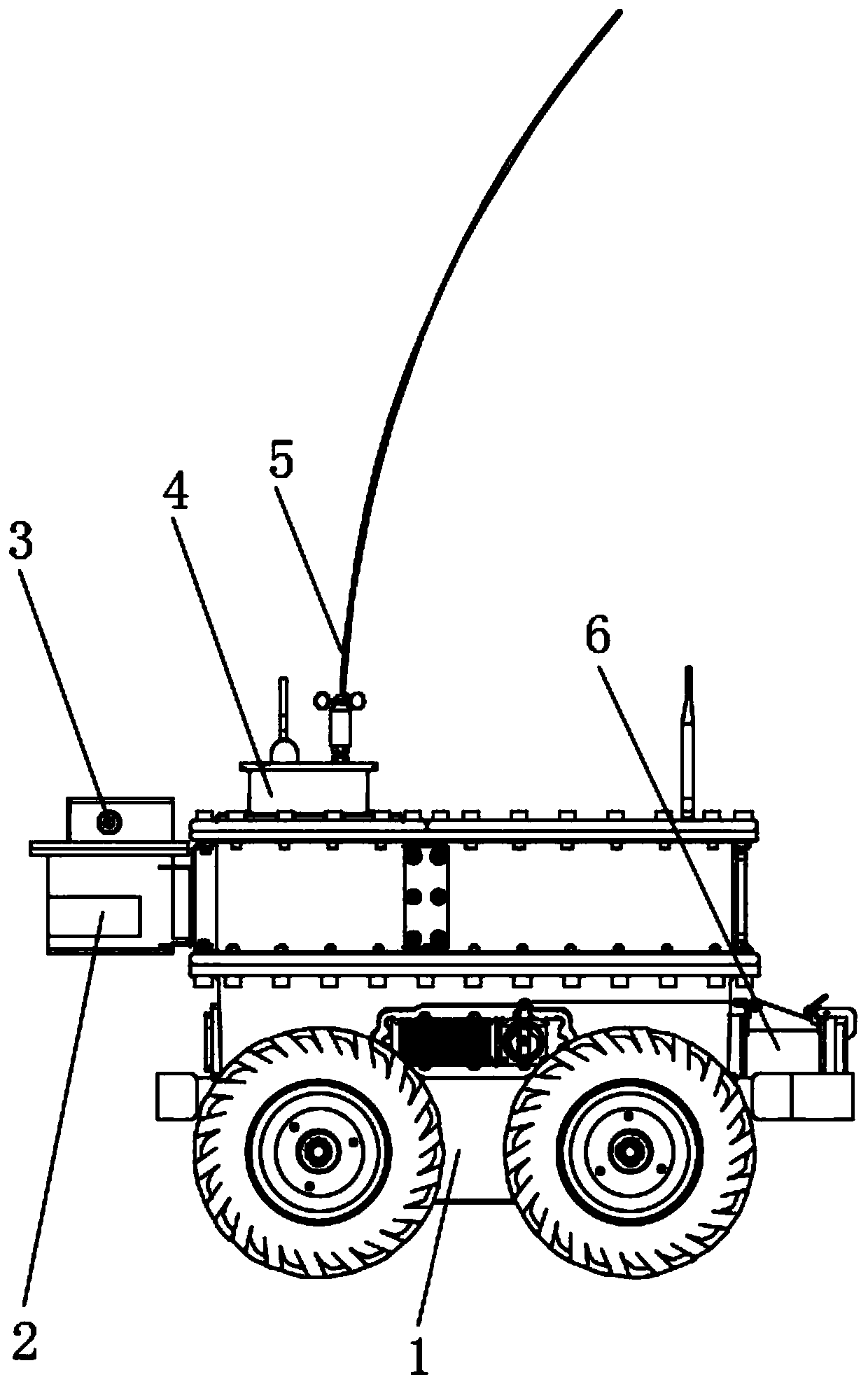

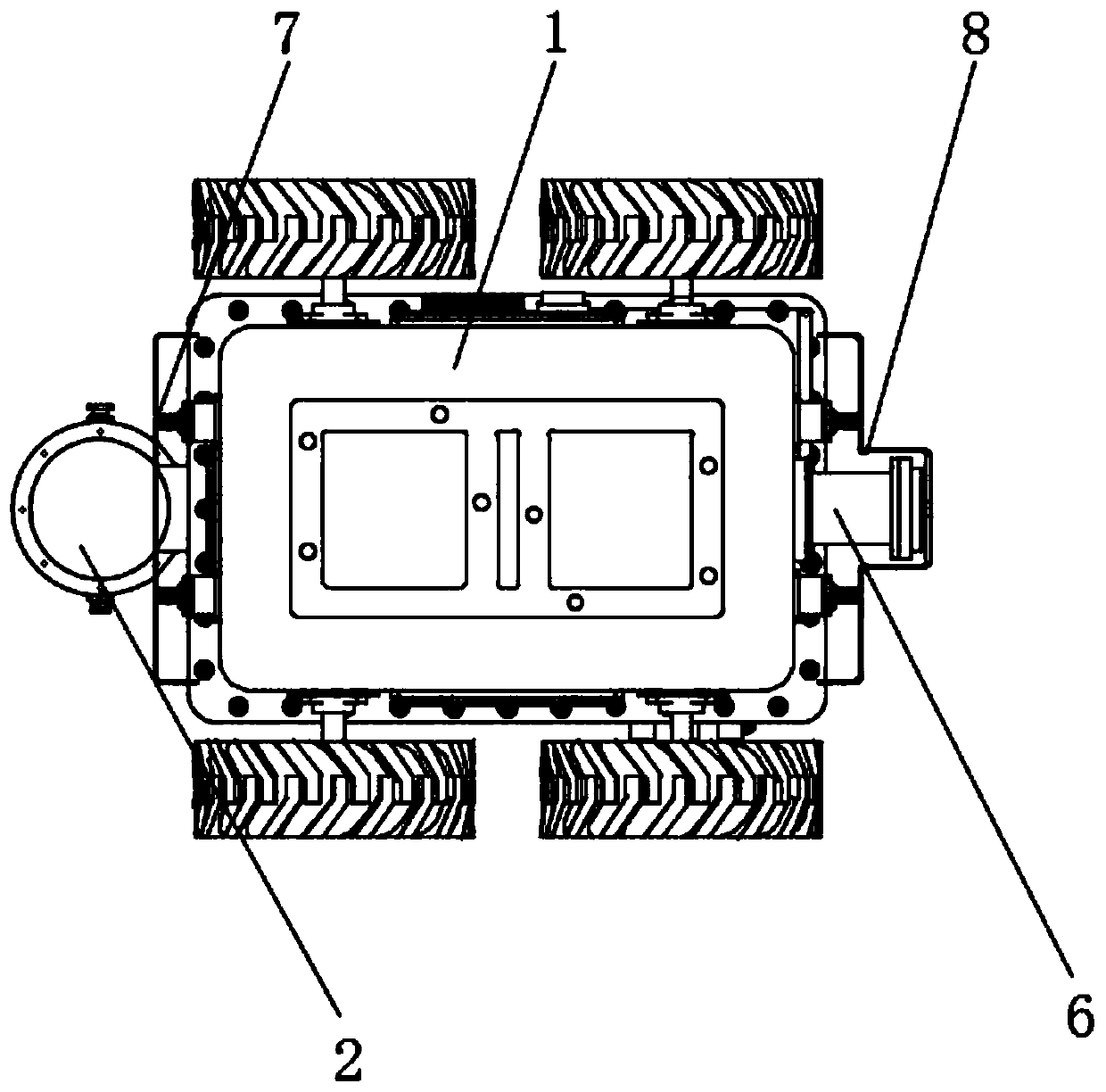

[0025] refer to Figure 1-3 As shown, a explosion-proof and intrinsically safe dangerous gas inspection robot, the dangerous gas inspection robot includes a robot, a driving chassis 1 installed at the bottom of the robot for driving the robot to walk, and a driving chassis 1 respectively installed at the front and rear ends of the driving chassis 1 The front anti-collision beam 7 and the rear anti-collision beam 8 used for robot collision protection, a detection mechanism for detecting dangerous gases is installed on the top of the drive chassis 1, and an environment collection mechanism is installed at the center of the front end of the drive chassis 1, wherein,

[0026] The detection mechanism includes a sensor box 4 installed on the outer surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com