Preparation method of hollow fiber membrane for removing carbon dioxide from natural gas

A carbon dioxide and fiber membrane technology, applied in chemical instruments and methods, membrane technology, gas fuel, etc., can solve the problems of poor permeation and separation performance of polymer membranes, achieve good industrial practicability, simple preparation method, and improve permeation selection performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

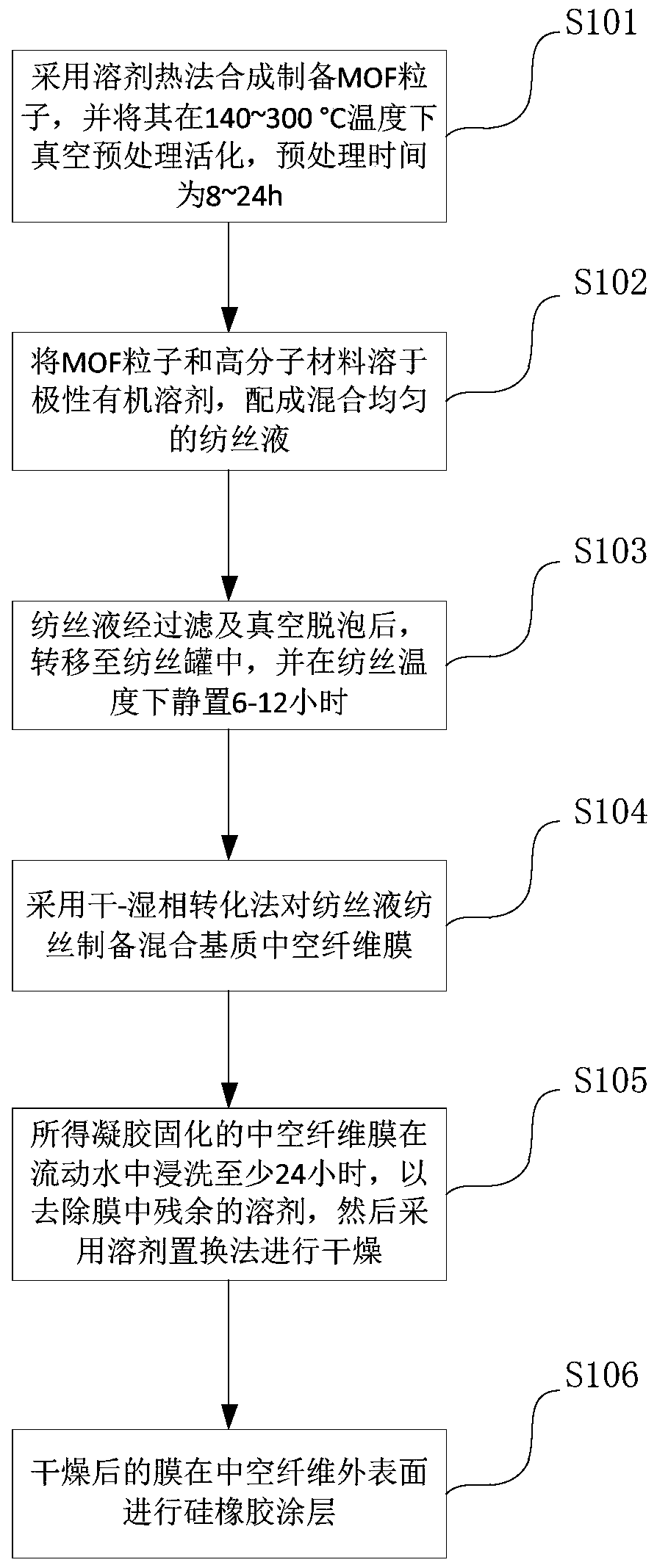

[0021] see figure 1 The method for preparing a hollow fiber membrane for removing carbon dioxide from natural gas provided by the embodiment of the present invention uses MOF (Metal-Organic Framework, metal-organic framework) as a dispersed phase to prepare a mixed-matrix hollow fiber membrane, which specifically includes the following steps:

[0022] Step S101, using solvothermal synthesis to prepare MOF particles, and pretreating and activating them under vacuum at a temperature of 140-300° C., and the pretreatment time is 8-24 hours.

[0023] In a specific application, the MOF particle is UiO-66-NH 2 , which is synthesized by the following solvothermal method: zirconium salt and 2-aminoterephthalic acid are dissolved in an organic solvent by ultrasonic and magnetic stirring in a preset ratio to obtain a light yellow solution; In a PTFE-lined high-pressure reactor, heat at high temperature for a certain period of time, cool and centrifuge to obtain yellow crystals, wash wit...

Embodiment 1-4

[0036] Chromium chloride and 2-aminoterephthalic acid (with a molar ratio of 1:1) were dissolved in N,N-dimethylformamide by ultrasonic and magnetic stirring to obtain a light yellow solution. Then transfer it to a high-pressure reaction kettle with PTFE lining, heat at a high temperature of 100-200°C for 8-96 hours, cool and centrifuge to obtain yellow crystals, wash with N,N-dimethylformamide, and then Purified by reflux in methanol, and finally dried in vacuum at a temperature of 70-150°C to obtain UiO-66-NH 2crystals. Vacuum activated UiO-66-NH at 200°C 2 The crystal is evenly dispersed in NMP by stirring and ultrasonic, and then part of the polyetherimide Add the solution prepared by 1000 / NMP into the dispersion liquid in batches, stir and ultrasonically mix evenly, and finally add the remaining required 1000. The concentration of 1000 is 32wt%, UiO-66-NH 2 The concentration in the total solid mass was 5%, and stirred for 12 hours to obtain a uniformly mixed spinn...

Embodiment 5

[0043] Chromium chloride and 2-aminoterephthalic acid (with a molar ratio of 0.5:1) were dissolved in N,N-dimethylformamide by ultrasonic and magnetic stirring to obtain a light yellow solution. Then transfer it to a high-pressure reactor with PTFE lining, heat at a high temperature of 100-200°C for 8-96 hours, cool and centrifuge to obtain yellow crystals, wash with N,N-dimethylformamide, and then Purified by reflux in methanol, and finally dried in vacuum at a temperature of 70-150°C to obtain UiO-66-NH 2 crystals. Vacuum activated UiO-66-NH at 200°C 2 The crystals are uniformly dispersed in NMP by means of stirring and ultrasonication, and then part of the polysulfone / DMF solution is added to the dispersion liquid in batches, mixed evenly by stirring and ultrasonication, and finally the remaining required polysulfone is added. The concentration of polysulfone is 30wt%, UiO-66-NH 2 accounted for 10% of the total solid mass, and stirred for 12 hours to obtain a uniformly m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com