Soy milk and preparation technology thereof

A preparation process, soybean milk technology, applied to other dairy products, dairy products, milking equipment, etc., can solve the problem that nisin cannot achieve auxiliary sterilization, achieve stable flavor and properties, low cost, and reduce sterilization time and the effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

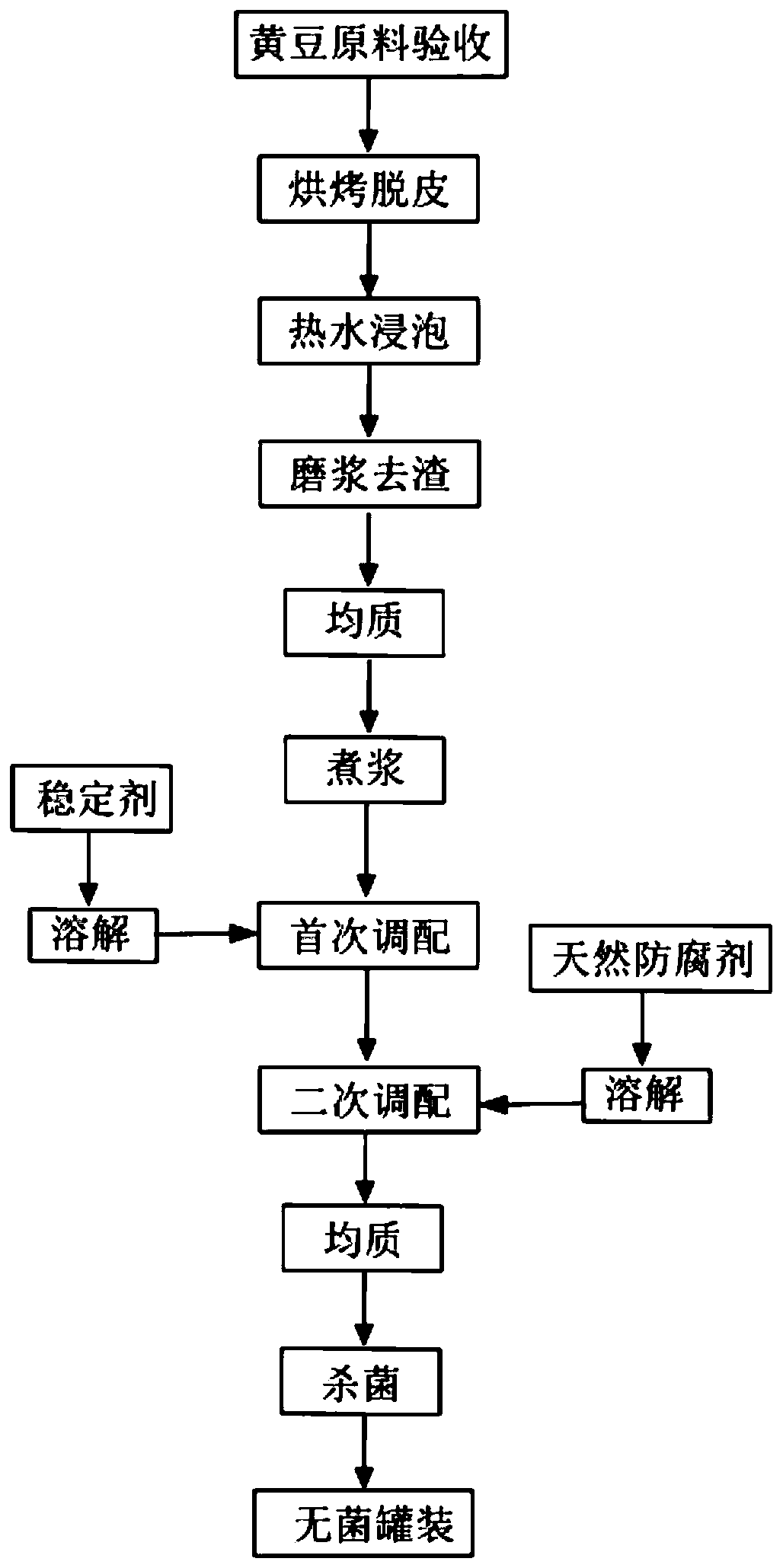

Method used

Image

Examples

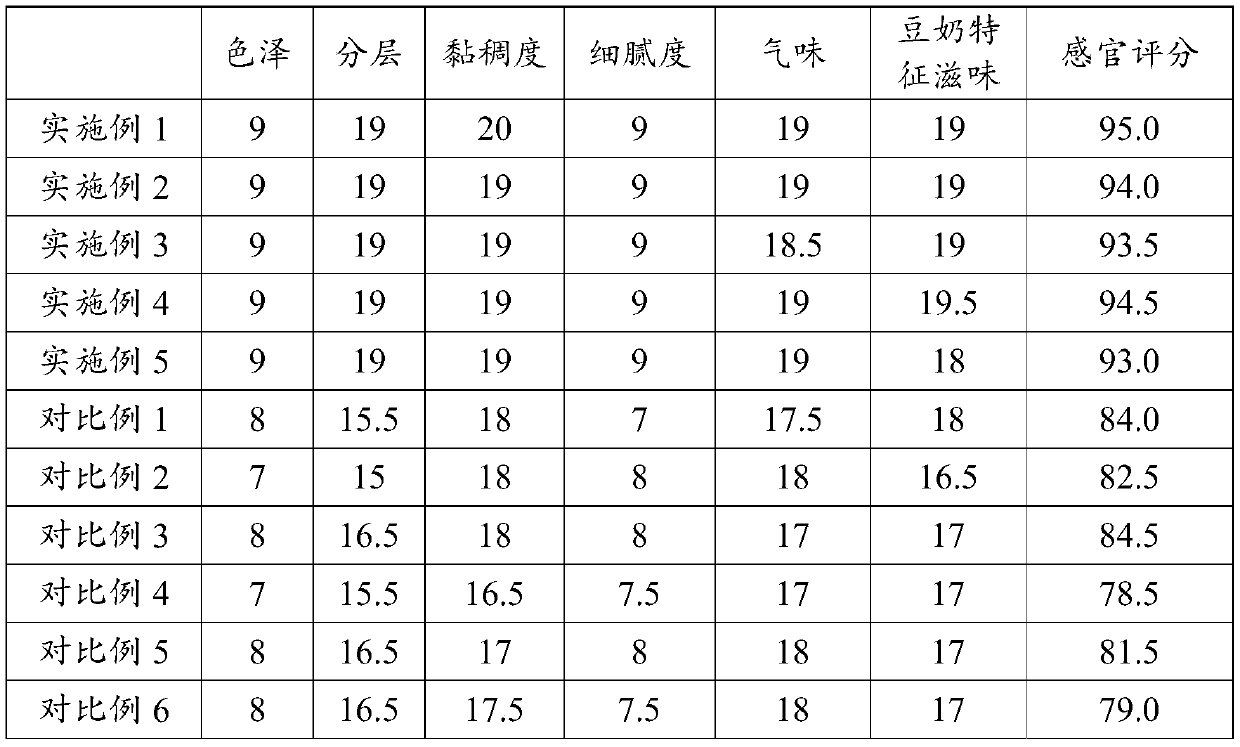

Embodiment 1

[0039] A preparation process of soybean milk, wherein the soybean milk comprises the following raw materials in mass percentage: 10% of soybeans, 5% of white sugar, 0.4% of table salt, 0.2% of vitamin E, 0.015% of nisin, 0.05% of microcrystalline cellulose, poly Glycerin fatty acid ester 0.05%, its specific operation steps are as follows:

[0040] (1) Preparation of soybean milk:

[0041] ①Soybean pretreatment

[0042] Bake the accepted soybeans at 85°C for 65 minutes, quickly cool and peel them after dry treatment, then add 90°C hot water and baking soda (the amount of baking soda added is 5% of the final soybean milk mass) to dissolve, stir, soak for 15 minutes and rinse 3 times.

[0043] ② Refining and homogeneity: use a colloid mill centrifuge to refine pulp and remove slag, the filter screen is 150 mesh, add water to dilute the bean dregs, dilute the bean dregs for secondary colloid mill centrifuge refining and remove slag, the filter screen is 150 mesh, and the slag af...

Embodiment 2

[0054] A preparation process of soybean milk, the soybean milk comprises the following raw materials in mass percentage: 8% of soybeans, 4% of white sugar, 0.2% of salt, 0.1% of vitamin E, 0.01% of gram polysaccharide, 0.08% of microcrystalline cellulose, polyglycerol Fatty acid ester 0.08%, its specific operation steps are as follows:

[0055] (1) Preparation of soybean milk:

[0056] ①Soybean pretreatment

[0057] Bake the accepted soybeans at 75°C for 60 minutes, dry them and quickly cool and peel them, then add 80°C hot water and baking soda (the amount of baking soda added is 4% of the final soybean milk mass) to dissolve, stir, soak for 10 minutes and rinse 2 times.

[0058] ② Refining and homogeneity: use a colloid mill centrifuge to refine pulp and remove slag, the filter screen is 150 mesh, add water to dilute the bean dregs, dilute the bean dregs for secondary colloid mill centrifuge refining and remove slag, the filter screen is 150 mesh, and the slag after deslag...

Embodiment 3

[0069] A preparation process of soybean milk, the soybean milk comprises the following raw materials in mass percentage: 14% of soybeans, 5% of white sugar, 0.5% of table salt, 0.3% of vitamin E, 0.02% of protamine, 0.08% of microcrystalline cellulose, polyglycerol Fatty acid esters 0.05%. The specific operation steps are as follows:

[0070] (1) Preparation of soybean milk:

[0071] ①Soybean pretreatment

[0072] Bake the accepted soybeans at 90°C for 60 minutes, quickly cool and peel them after dry treatment, then add 90°C hot water and baking soda (the amount of baking soda added is 5% of the final soybean milk mass) to dissolve, stir, soak for 20 minutes and then rinse 4 times.

[0073] ② Refining and homogeneity: use a colloid mill centrifuge to refine pulp and remove slag, the filter screen is 150 mesh, add water to dilute the bean dregs, dilute the bean dregs for secondary colloid mill centrifuge refining and remove slag, the filter screen is 150 mesh, and the slag a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com