Method for predicting effective elastic modulus of short fiber composite material based on mesomechanics

A technology of composite materials and mesomechanics, applied in CAD numerical modeling, electrical digital data processing, design optimization/simulation, etc., can solve problems such as difficulties in predicting transverse elastic modulus and shear modulus, and failure to meet engineering requirements , to achieve the effect of improving practical value, improving calculation accuracy and calculation efficiency, and reducing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

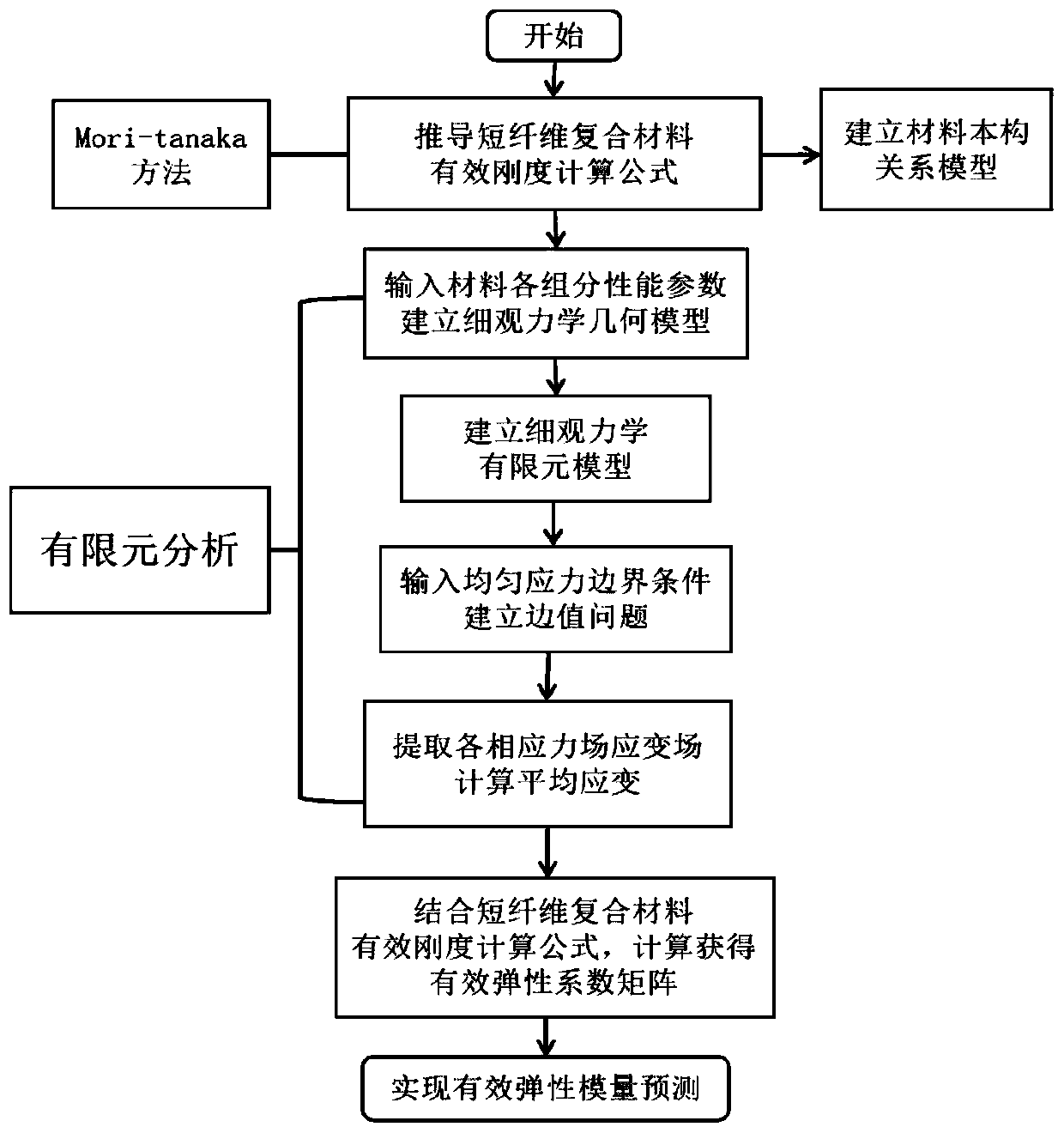

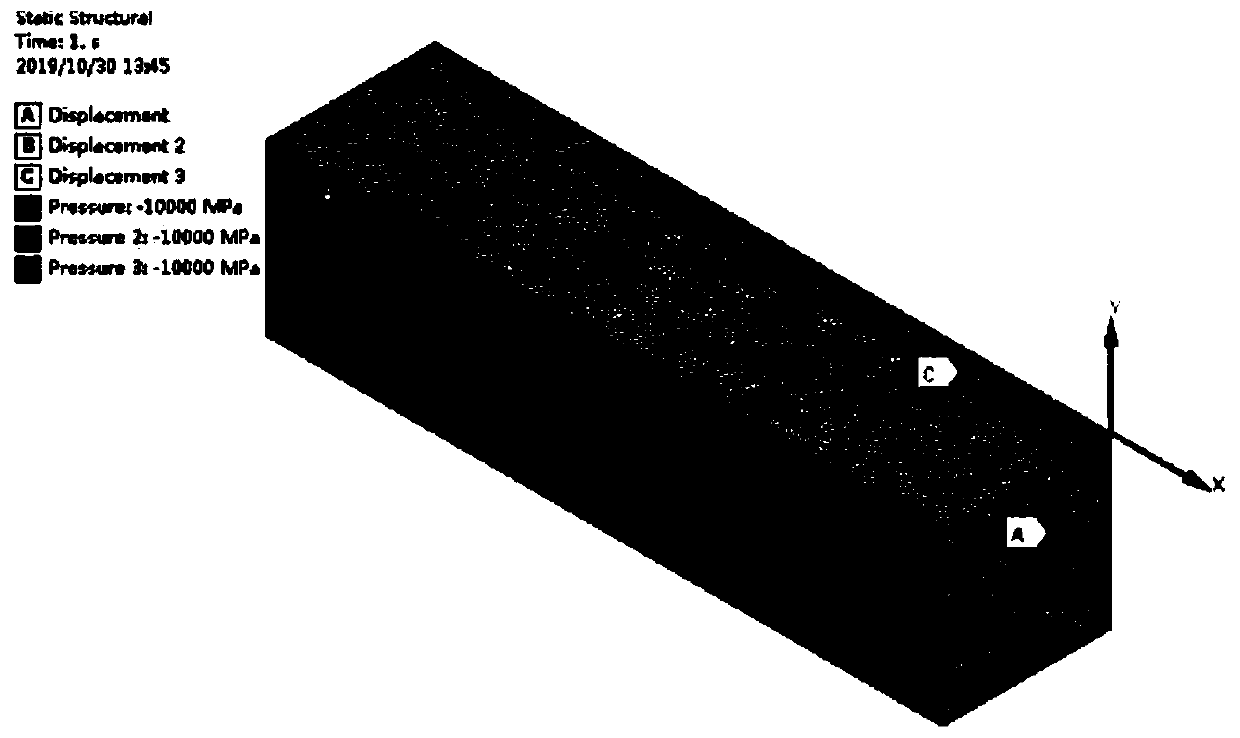

[0050] In conjunction with the accompanying drawings, the prediction of the effective modulus of elasticity of a kind of micron chopped carbon fiber reinforced polyphenylene sulfide resin matrix composite material (PPS / CF) is an embodiment, such as Figure 1-4 shown. The method for predicting the mechanical properties of short fiber composite materials disclosed in this embodiment, the specific implementation steps are as follows:

[0051] Step 1: Based on the Mori-tanaka equivalent inclusion principle and the average stress principle, the effective stiffness calculation formula of the short fiber composite material is derived, and the material constitutive model is established. The material constitutive model includes anisotropic material constitutive relation model, isotropic material constitutive relation model and transversely isotropic material constitutive relation model.

[0052] Based on the Mori-tanaka equivalent inclusion principle and the average stress principle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com