Large-thickness high-strength heat-resistant steel plate and production method thereof

A production method and a large-thickness technology, applied in the field of metallurgy, can solve the problems of great impact on economic benefits, high applicable temperature of steel plates, complex production process, etc., and achieve the effects of simple process, high temperature strength and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

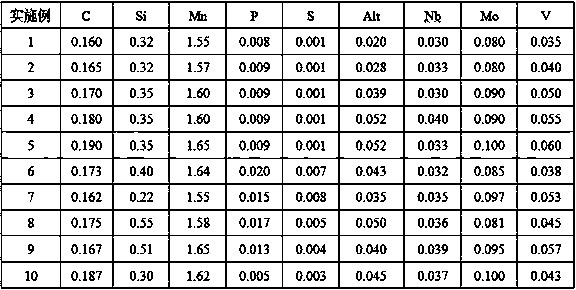

Examples

Embodiment 1

[0019] The production method of the large-thickness high-strength heat-resistant steel plate in this embodiment includes the steps of billet heating, controlled rolling and heat treatment. The control parameters of each process are as follows:

[0020] Heating process: the highest billet heating temperature is 1280°C, the soaking temperature is 1250°C, and the heating time is 10.5min / cm;

[0021] Controlled rolling process: two-stage rolling process is adopted, the rolling temperature of the first stage is 1000°C; ℃;

[0022] Heat treatment process: normalizing process is adopted, the normalizing temperature is 910°C, the thermal insulation coefficient is 2.2min / mm, and the steel plate is cooled in water for 3min after it is released from the furnace.

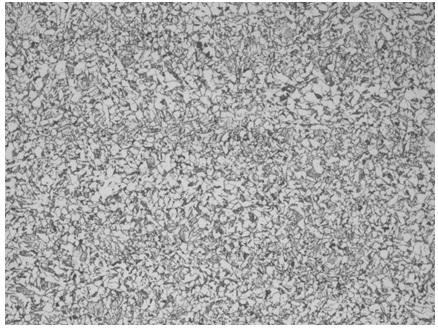

[0023] The thickness of the large-thickness high-strength heat-resistant steel plate of this embodiment is 40mm, and its metallographic structure is as follows figure 1 As shown, it can be seen from the figure that the struc...

Embodiment 2

[0026] The production method of the large-thickness high-strength heat-resistant steel plate in this embodiment includes the steps of billet heating, controlled rolling and heat treatment. The control parameters of each process are as follows:

[0027] Heating process: the highest billet heating temperature is 1280°C, the soaking temperature is 1243°C, and the heating time is 10min / cm;

[0028] Controlled rolling process: two-stage rolling process is adopted, the rolling temperature of the first stage is 1010°C; ℃;

[0029] Heat treatment process: normalizing process is adopted, the normalizing temperature is 920°C, the thermal insulation coefficient is 2.5min / mm, and the steel plate is cooled in water for 4min after it comes out of the furnace.

[0030] In this embodiment, the thickness of the large-thickness high-strength heat-resistant steel plate is 40mm, and the structure of the steel plate is pearlite plus ferrite, of which pearlite accounts for 28%. The internal struc...

Embodiment 3

[0033] The production method of the large-thickness high-strength heat-resistant steel plate in this embodiment includes the steps of billet heating, controlled rolling and heat treatment. The control parameters of each process are as follows:

[0034] Heating process: the highest billet heating temperature is 1280°C, the soaking temperature is 1240°C, and the heating time is 10.2min / cm;

[0035] Controlled rolling process: two-stage rolling process is adopted, the rolling temperature of the first stage is 1150°C; ℃;

[0036] Heat treatment process: normalizing process is adopted, the normalizing temperature is 910°C, the thermal insulation coefficient is 2.2min / mm, and the steel plate is cooled in water for 4min after it comes out of the furnace.

[0037] In this embodiment, the thickness of the large-thickness high-strength heat-resistant steel plate is 70 mm. The structure of the steel plate is pearlite plus ferrite, of which pearlite accounts for 25%. The internal struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com