Smelting system and method of stibnite

A technology for stibnite and vacuum smelting, applied in the direction of improving process efficiency, improving energy efficiency, etc., can solve the problems of low recovery rate of antimony metal and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

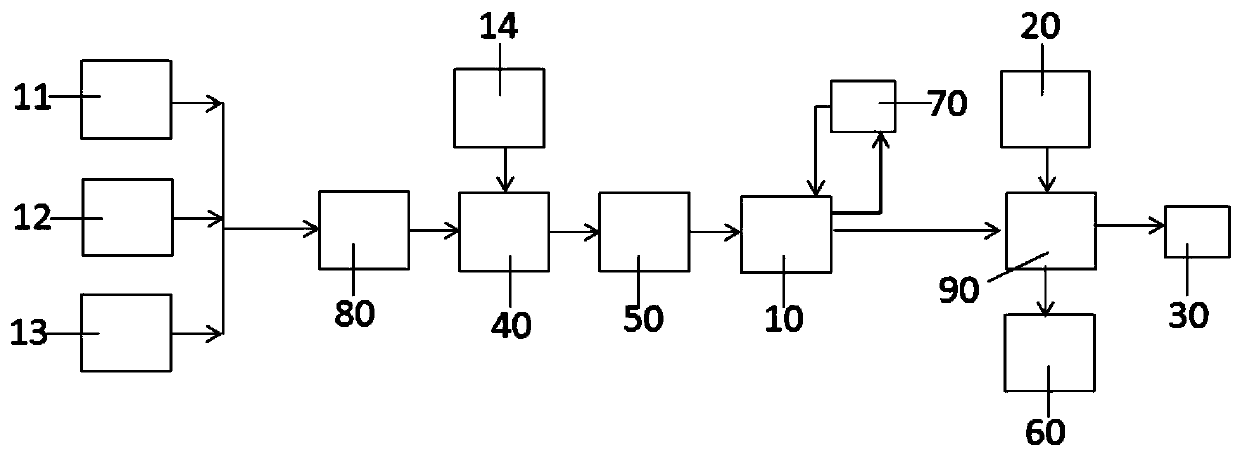

Method used

Image

Examples

preparation example Construction

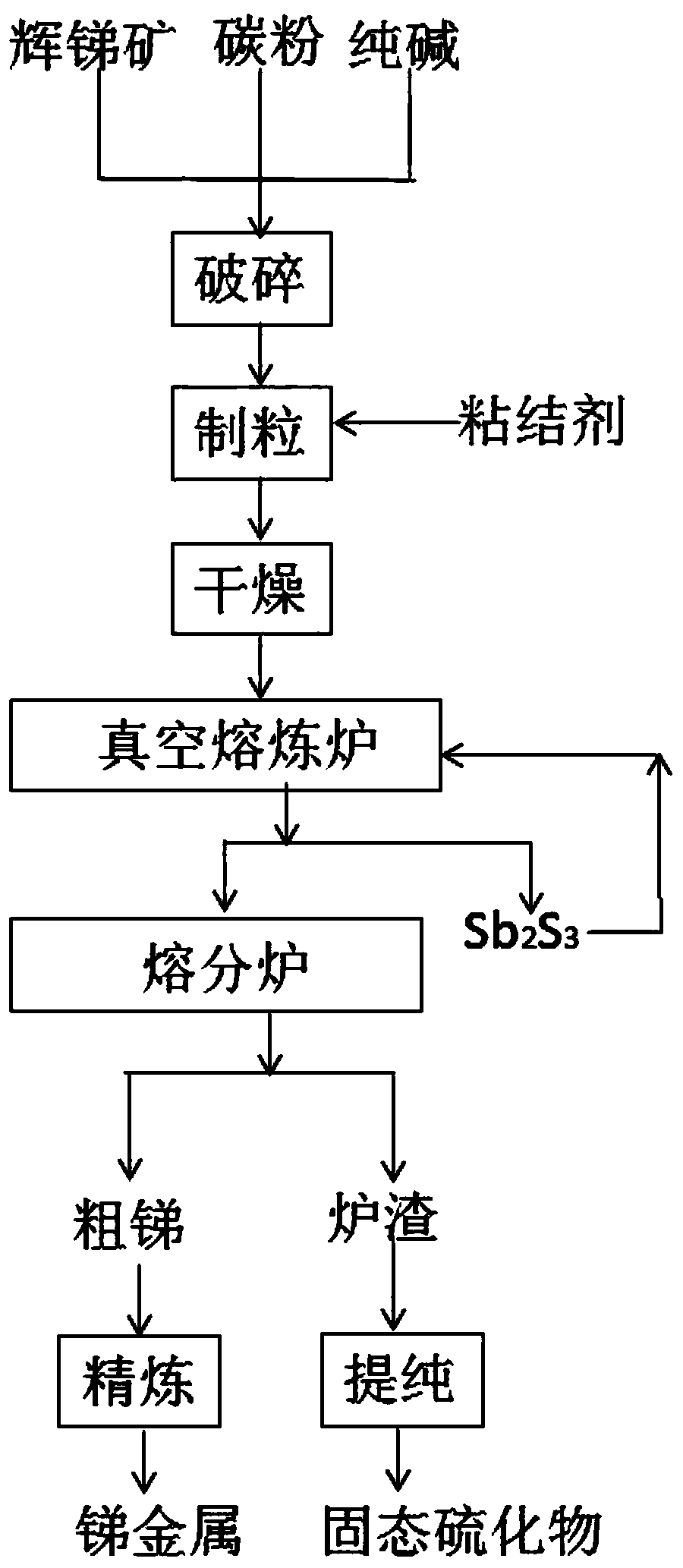

[0050] In a preferred embodiment, the above preparation method further includes: adding a binder during the vacuum melting process. The addition of the binder is beneficial to improve the cohesive force of the stibnite, the reducing fuel and the basic additive, and further helps to improve the precise ratio of the raw materials in the reaction process. More preferably, the adhesives include, but are not limited to, pellet adhesives, silicone epoxy adhesives, UV curable adhesives, hot melt adhesives, pressure sensitive adhesives, polyurethane adhesives, waste molasses, and epoxy adhesives. one or more of the agents.

[0051] In a preferred embodiment, the binder is used in an amount of 0.2-15% based on the weight percentage of the stibnite. The amount of the binder includes but is not limited to the above-mentioned range, and limiting it within the above-mentioned range is beneficial to further improving the binding force of the stibnite, the reducing agent and the basic addit...

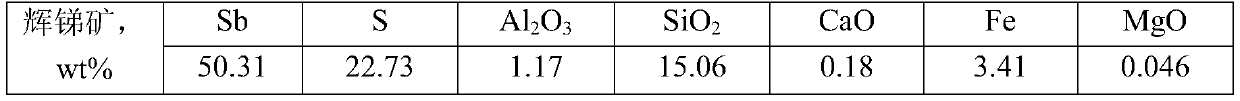

Embodiment 1

[0068] The amount of stibnite added is 2t, the amount of carbon powder added is 0.12t, and the amount of soda ash added is 1.4t. Mix the above raw materials evenly, and then add 0.1t of waste sucrose water to the mixture. After stirring evenly, pelletize Granulate in the machine to obtain pellets with a diameter of 0.5 cm. Afterwards, the produced pellets are put into a vacuum smelting device 10 (electric furnace) for vacuum smelting. The pressure in the furnace is 50Pa, the smelting temperature is 600°C, and the smelting time is 5 hours; the antimony-containing pellets are smelted in a vacuum furnace, and the antimony-containing pellets are put into the melting furnace 90 (electric furnace) for melting in a hot state. The material is heated to 1200°C and kept for 2 hours to produce crude antimony and slag. The results show that the yield of crude antimony is 0.96t, and the crude antimony contains 99.2% antimony.

Embodiment 2

[0070] The addition amount of stibnite is 3t, the addition amount of carbon powder is 0.18t, and the addition amount of soda ash is 2.1t. The above raw materials are mixed evenly, and then 0.15t waste sucrose water is added to the mixture. (disc pelletizer) to obtain pellets with a diameter of 0.5 cm. Afterwards, the produced pellets are put into a vacuum smelting device 10 (electric furnace) for the first vacuum smelting. The pressure in the furnace is 50Pa, the smelting temperature is 600°C, and the smelting time is 6 hours; the antimony-containing pellets are obtained by smelting in a vacuum furnace, and the antimony-containing pellets are put into the melting furnace 90 (electric heating furnace) in a hot state for melting , the furnace is heated to 1200 ° C, after 2 hours of heat preservation, the output of crude antimony and slag. The results show that the output of crude antimony is 1.51t, and the crude antimony contains 99.1% of antimony.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com