Ultrasonic quenching device capable of online decoking and application thereof

An ultrasonic and quenching technology, which is applied to cleaning methods and appliances, cleaning methods using liquids, cleaning hollow objects, etc., can solve problems such as easy coking of pyrolysis quench coolers, affecting work efficiency, and inability to realize online regeneration, etc., and achieve an increase in operating cycle , prolong the operation cycle, the effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

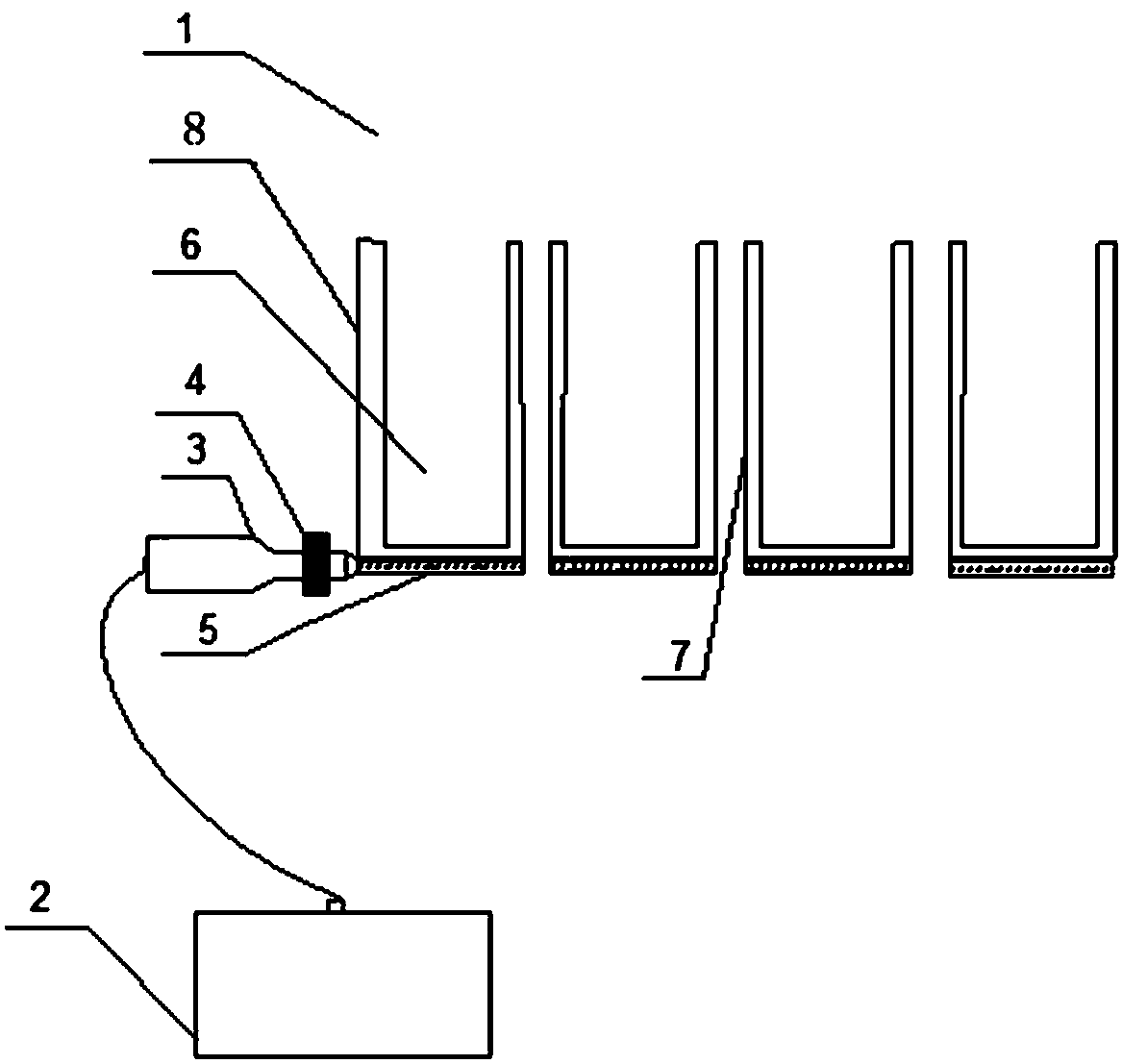

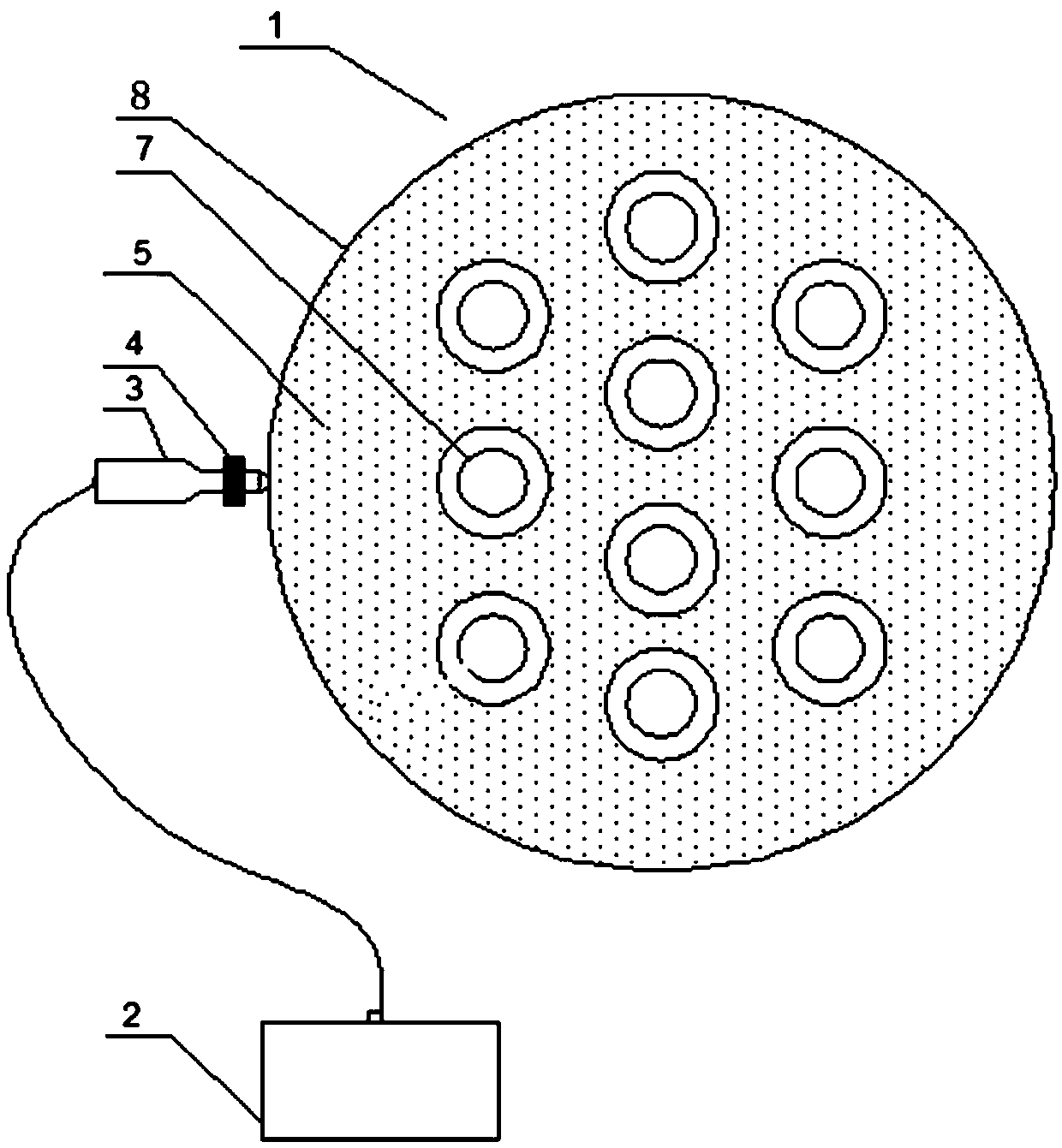

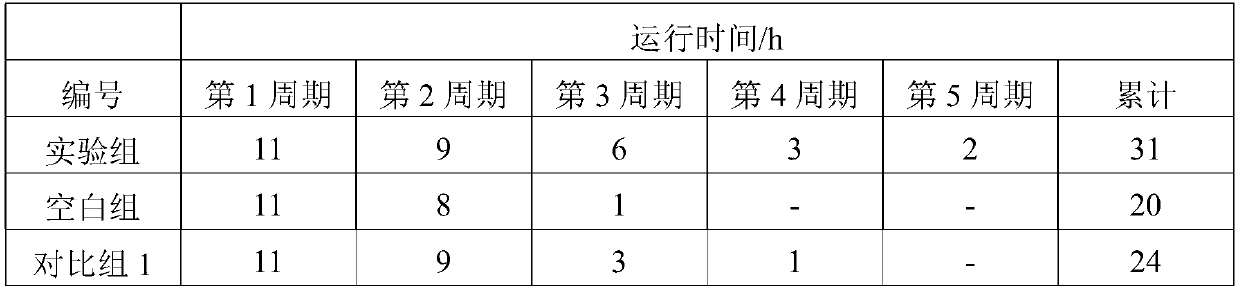

[0035] Such as Figure 1-2 As shown in the structure, the ultrasonic quencher device capable of online decoking according to the present invention includes a quencher body 1, and a plurality of tube passes 7 are arranged inside the quencher body 1 for heat exchange of high-temperature cracking products. Quenching; and between the quencher outer wall 8 of the quencher body 1 and the side wall of the tube pass 7 forms a shell side 6 containing the quenching medium, and the high-temperature pyrolysis product circulating in the tube side 7 and the The quenching medium flowing in the shell side 6 performs heat exchange to realize the quenching of the high-temperature cracking product. In the ultrasonic quenching device of the present invention, the quenching medium is water.

[0036] In the ultrasonic quencher device of the present invention, the pipe-side material entering the pipe-side 7 is the high-temperature cracked product after reaction, mainly including ethylene, propylene, a...

Embodiment 2

[0049] The cracking quenching process of the present invention is implemented by the ultrasonic quenching device capable of on-line decoking, and the high-temperature cracking reaction product enters through the sieve inlet of the ultrasonic distributor 5 and the sieve inlet of the tube pass 7 sequentially In the quenching device, after quenching, the cracking reaction product leaves the quenching device through the exit of the tube pass 7 of the quenching device. The hot water enters the quenching device from the inlet of the shell side 6 of the quenching device. The hot water and the high temperature cracking reaction product in the tube pass Heat exchange, the hot water absorbs the heat of the high-temperature pyrolysis gas and converts it into high-temperature and high-pressure steam, which leaves the quencher at the exit of the shell side of the quencher. The high-temperature material at the entrance of the tube pass of the device and the low-temperature material entering t...

Embodiment 3

[0051] The online decoking process of the present invention is a regeneration process of the quencher. The quencher with a coking layer on the inner wall of the tube side is subjected to online decoking treatment, that is, the ultrasonic quenching device capable of online decoking is implemented .

[0052] The on-line decoking process of the present invention is carried out by passing hot water with a temperature of 30°C to 95°C through the tube side of the quencher. The hot water enters from the inlet of the quench cooler, first passes through the sieve plate of the ultrasonic distributor 5, and then enters the tube pass of the quench cooler. It leaves the quench cooler from the tube pass exit of the quench cooler, and the shell pass of the quench cooler flows into 30℃ at the same time. -95℃ hot water, as far as possible to allow multiple tube passes and shell passes to experience ultrasonic action at the same time. The ultrasonic generator 2 converts electrical energy into mech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com