Industrial production sludge purification tank used in field of environmental protection

A technology for purifying tanks and sludge, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

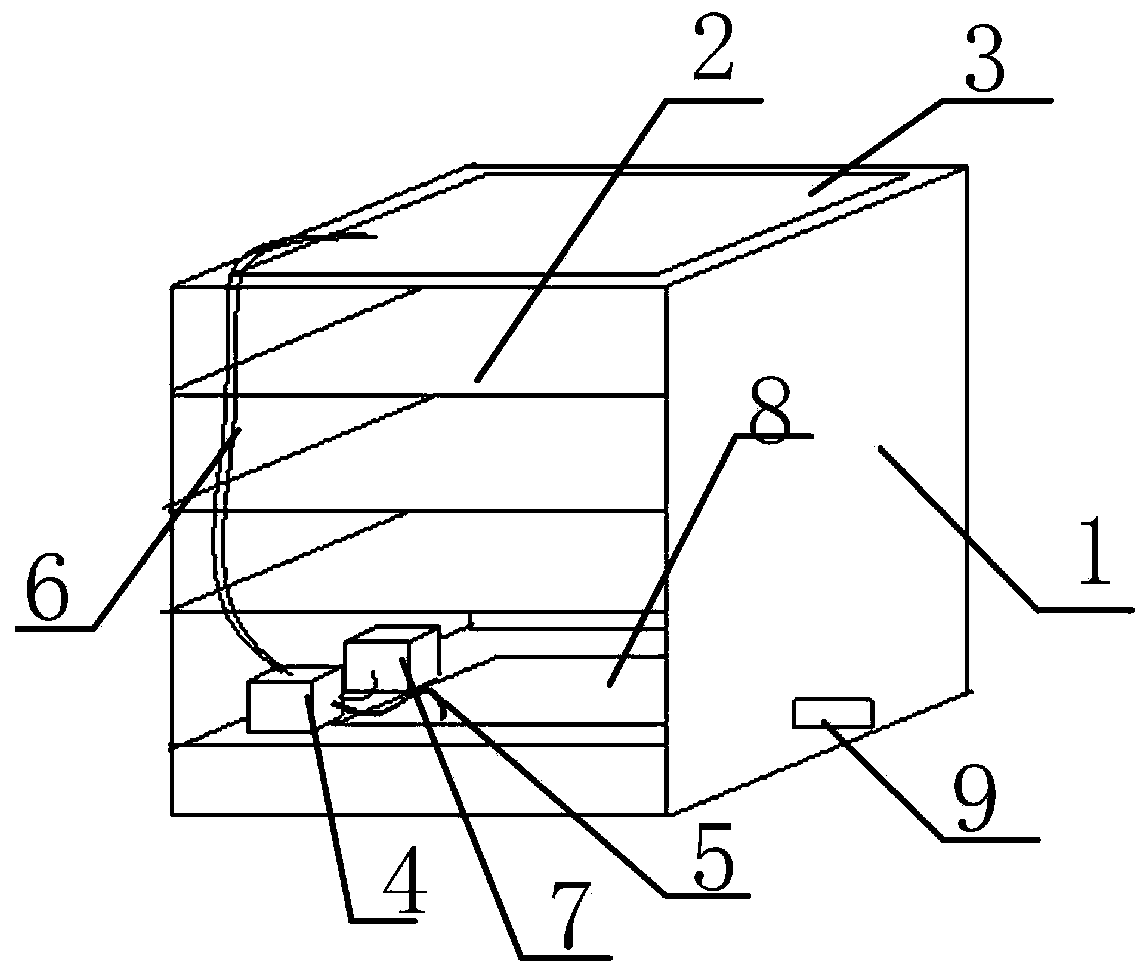

[0014] The technical solutions in the embodiments of the present invention will be described below with reference to the drawings in the embodiments of the present invention.

[0015] In order to achieve secondary utilization of sludge on the premise of saving water, an embodiment of the present invention provides an industrial production sludge purification tank used in the field of environmental protection.

[0016] An industrial production sludge purification tank used in the field of environmental protection provided by the embodiment of the present invention includes: a tank body 1, a plurality of filter layers 2 are arranged on the tank body 1, and each filter layer 2 is parallel to each other , and from top to bottom in the tank body 1, the filtration performance of the filter layer 2 is sequentially enhanced;

[0017] A water outlet is provided at the opening 3 of the tank body 1, a water storage tank 8 is provided at the bottom of the tank body 1, and a water pump 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com