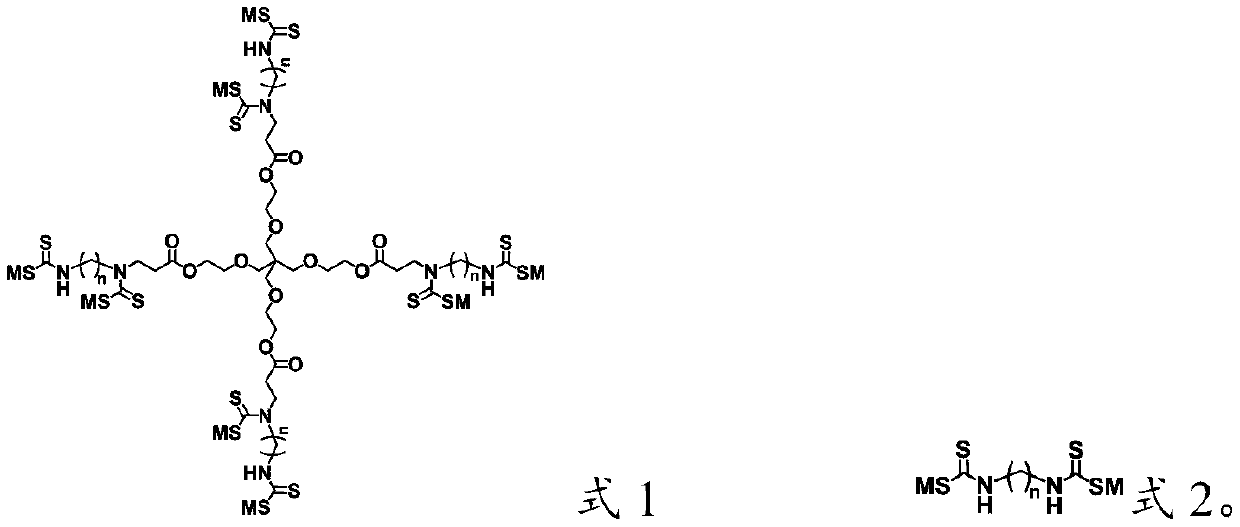

Composite heavy metal chelating agent containing dithiocarboxylate functionalized ethoxylated pentaerythritol core hyperbranched polymer

A technology of heavy metal chelating agent and hyperbranched polymer, which is applied in the fields of organic chemistry, water pollutants, chemical instruments and methods, etc., can solve the problem that the concentration of heavy metals cannot meet the discharge standards, cannot handle complex heavy metal wastewater, and the linear molecular chain is easy to Curl and other problems, to achieve good flocculation and sedimentation performance, good chemical stability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

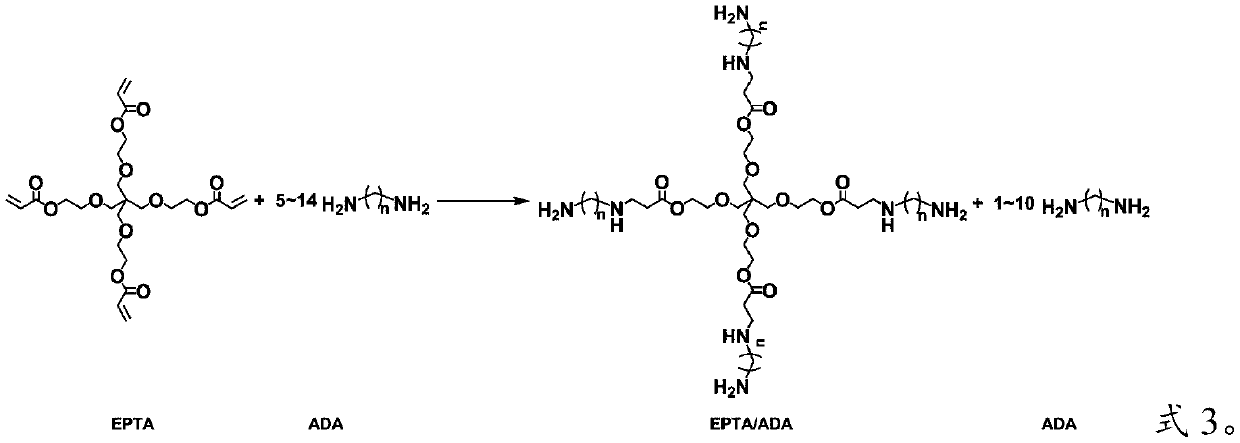

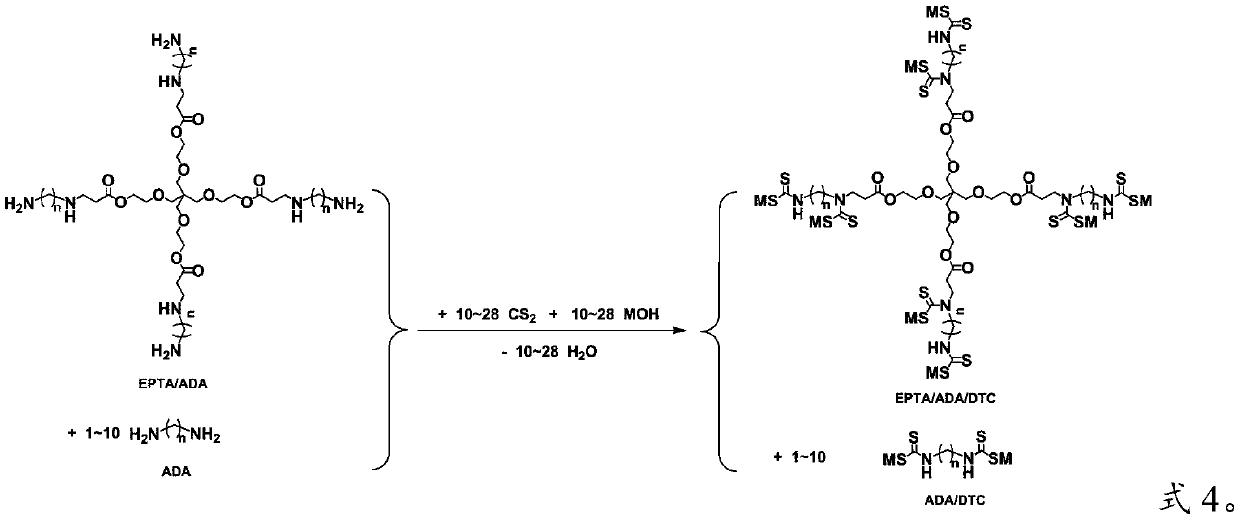

Method used

Image

Examples

Embodiment 1

[0036] Preparation of dithiocarboxylate functionalized pentaerythritol core hyperbranched polymer and ethylenediamine-N,N'-bisdithiocarboxylate sodium complex heavy metal chelating agent:

[0037] Under nitrogen protection, add 36.00g (0.60mol) ethylenediamine (EDA for short) and 36.00g methanol respectively in the round bottom flask with stirring, reflux condenser, constant pressure dropping funnel and thermometer, start stirring And control the temperature at 25°C; then mix 52.80g (0.10mol) ethoxylated pentaerythritol tetraacrylate (EPTA) and 52.80g methanol into the dropping funnel, and drop them into the ethylenediamine solution in the round bottom flask in three equal parts In , the interval time of each batch of addition is 6h. After the dropwise addition, react at 25°C for 28 hours to obtain an intermediate——ethoxylated pentaerythritol tetrakis((N-(2-aminoalkylene))-3-aminopropionate) hyperbranched polymer and ethylenediamine mixed methanol solution. Then, cool to 20°...

Embodiment 2

[0041] Preparation of dithiocarboxylate functionalized pentaerythritol core hyperbranched polymer and butanediamine-N,N'-bisdithiocarboxylate sodium complex heavy metal chelating agent:

[0042] Under nitrogen protection, 52.80g (0.60mol) of butanediamine (1,4-Butanediamine, hereinafter referred to as BDA) and 52.80g of ethanol were respectively added to the round bottom with stirring, reflux condenser, constant pressure dropping funnel and thermometer In the flask, start stirring and control the temperature at 25°C; then mix 52.80g (0.10mol) of ethoxylated pentaerythritol tetraacrylate (EPTA) with 52.80g of ethanol, place it in the dropping funnel, and drop it into the round bottom in three equal parts. In the ethylenediamine solution in the flask, the interval between the addition of each batch is 6h. After the dropwise addition, react at 25°C for 28 hours to obtain an intermediate——ethoxylated pentaerythritol tetrakis((N-(4-aminoalkylene))-3-aminopropionate) hyperbranched p...

Embodiment 3

[0046] Preparation of dithiocarboxylate functionalized pentaerythritol core hyperbranched polymer and hexamethylenediamine-N,N'-bisdithiocarboxylate sodium complex heavy metal chelating agent:

[0047] Under the protection of nitrogen, 81.20g (0.70mol) of hexamethylenediamine ((1,6-Hexanediamine, referred to as HDA) and 81.20g of ethanol were respectively added to the round bottom with stirring, reflux condenser, constant pressure dropping funnel and thermometer. In the flask, start stirring and control the temperature at 20°C; then mix 52.80g (0.10mol) of ethoxylated pentaerythritol tetraacrylate (EPTA) with 52.80g of ethanol, place it in the dropping funnel, and drop it into the round bottom flask twice In the middle, first drop one-half, stir for 4h, and then drop the remaining one-half. After the dropwise addition, react at 25°C for 24 hours to obtain the intermediate——ethoxylated pentaerythritol tetrakis((N-(6 -aminoalkylene))-3-aminopropionate) hyperbranched polymer and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com