Preparation method of mortise and tenon joint carbon fiber composite laminate plate

A technology of composite material layer and composite material, which is applied in the field of preparation of carbon fiber composite laminates, and can solve problems such as eccentric loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

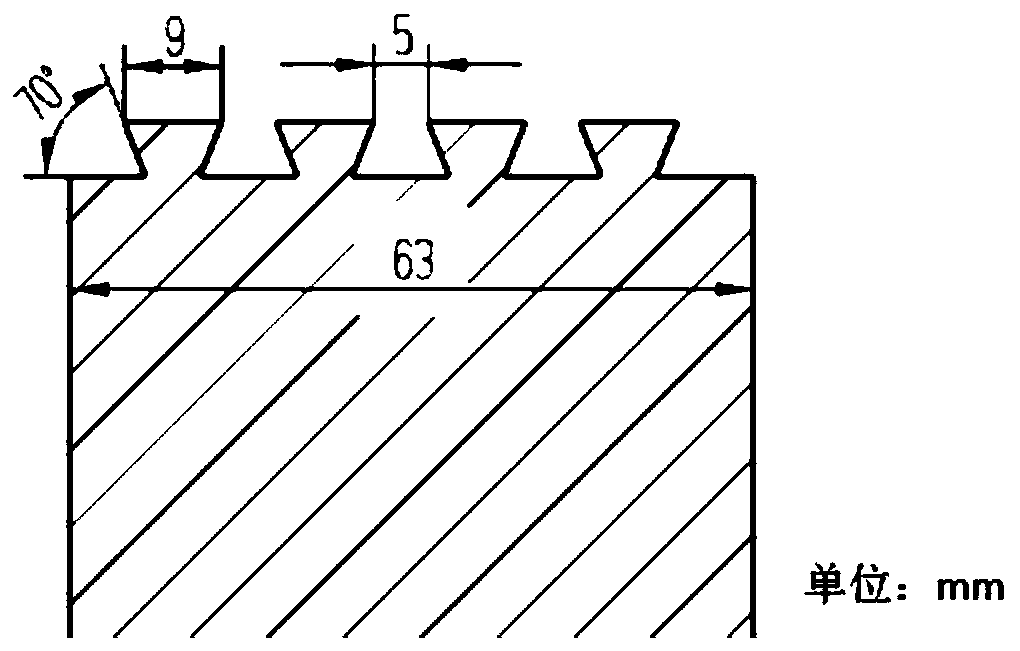

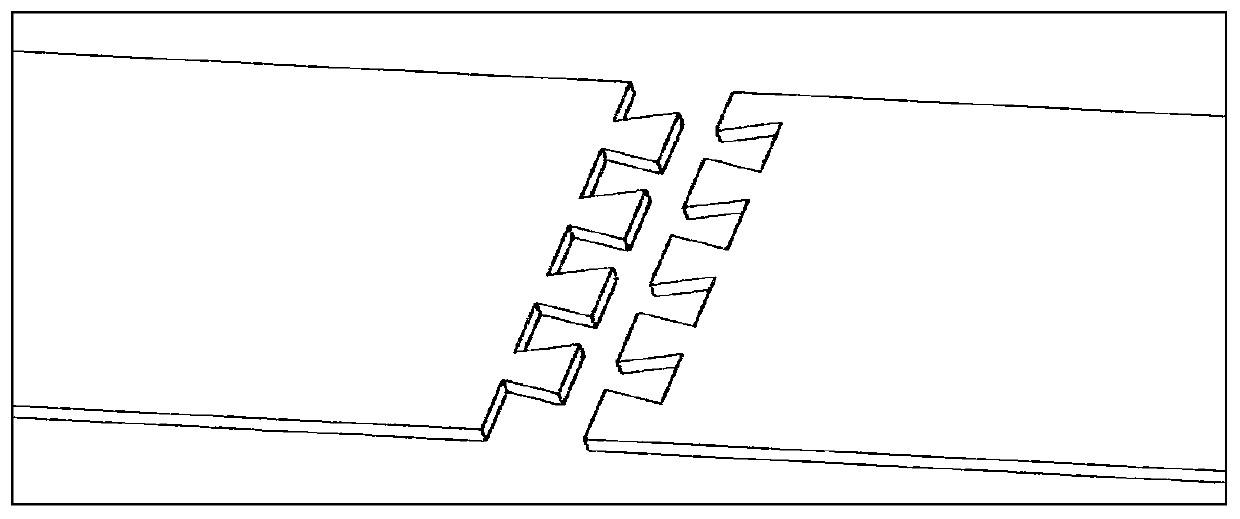

[0026] A method for preparing a mortise and tenon joint carbon fiber composite laminate, comprising the following steps:

[0027] (1) Preparation of the carbon fiber composite laminate of the laminate structure: take the width direction of the carbon fiber composite laminate of the laminate structure as the 90° direction, and place the TY carbon fiber from top to bottom according to 70°, -70° , 90°, -70°, and 70° in order to lay up 5 layers in total, and the thickness of each layer of carbon fiber is 1mm; the layered TY carbon fiber is vacuum packaged, and HYG epoxy resin matrix is injected between each layer of carbon fiber, and placed Carry out hot press molding in a hot autoclave. The hot press molding process is to raise the temperature to 145°C, keep the temperature for 50 minutes, then add an external pressure of 1MPa, then keep the pressure and continue to heat up to 180°C, keep the heat for 3 hours, and then press at a constant speed. Cool down to below 60°C, restore...

Embodiment 2

[0031] The laminated board of this embodiment is the same as that of Embodiment 1, the difference is that in the step (1), the laying angle a=45, the internal angle of the corresponding isosceles trapezoidal tenon and tenon is 45 °, and the temperature of thermocompression forming is 150 °C, keep warm for 30min; the curing temperature in step (3) is 100 °C.

Embodiment 3

[0033] The laminated board of this embodiment is the same as that of Embodiment 1, the difference is that in step (1), the laying angle a=60, the inner angle of the corresponding isosceles trapezoidal mortise and tenon is 60°, and the temperature of thermocompression forming is 143°C. °C, keep warm for 40min; the curing temperature in step (3) is 110 °C.

[0034] The method of the invention can effectively solve the defects of the prior art laminated board connection method, and the prepared laminated board can greatly improve the bearing capacity of the overall connection; and the carbon fiber layup at the mortise and tenon joint is well preserved, which can ensure that the carbon fiber is in a complete and continuous under high load conditions; since the two laminates are at the same level, the use of mortise and tenon joints can avoid the failure form of tearing at the joint caused by eccentric loads, and it can also provide stronger strength for thicker laminates. Bearing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com