Preparation method of building shock insulation rubber support and building shock insulation rubber support prepared by applying same

A vibration-isolating rubber and construction technology, which is applied to buildings, building components, building types, etc., can solve problems such as low vulcanization efficiency, and achieve the effects of reducing energy consumption, precise vulcanization time control, and shortening vulcanization time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

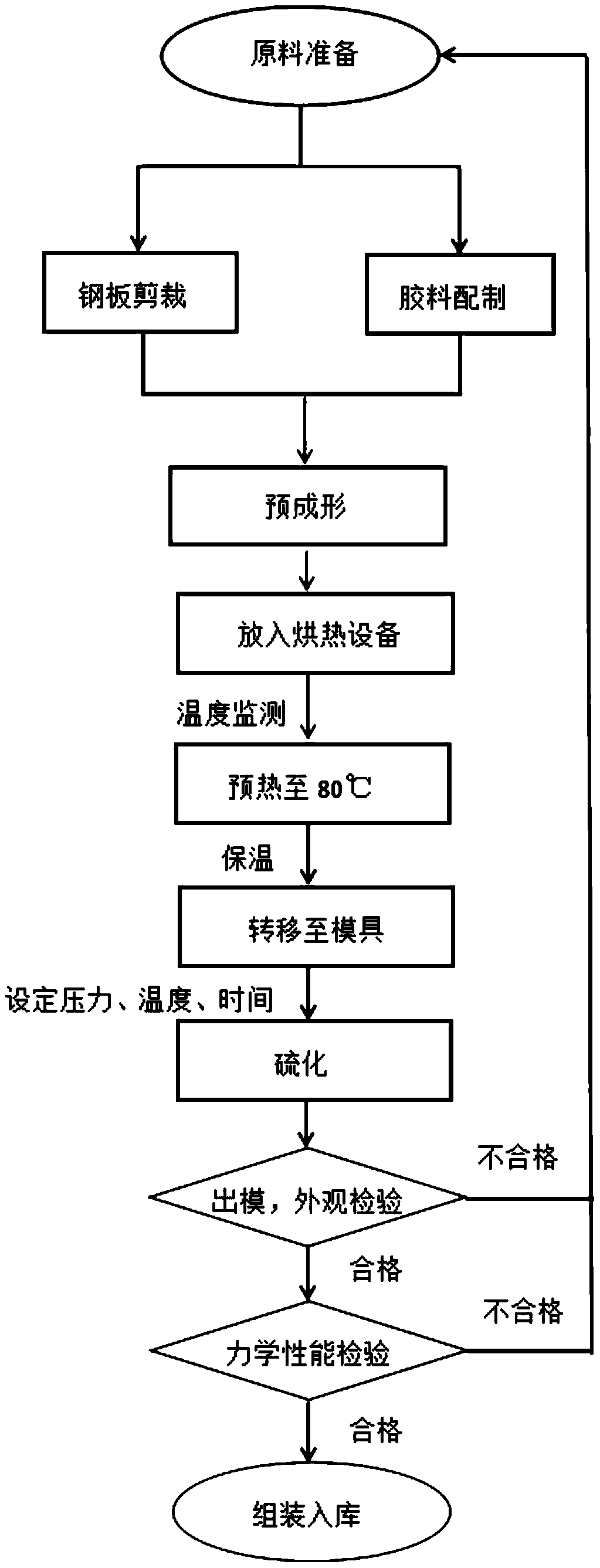

[0043] The invention provides a building shock-isolation rubber bearing, and the preparation method comprises the following steps:

[0044] a) Preparation of rubber compound: preparing and processing the rubber compound according to the formula;

[0045] b) Cut the steel plate according to the size requirements;

[0046] c) After the mixed rubber is rolled back and cut into pieces, the adhesive is bonded to the cut steel plate to form a semi-finished product to be molded;

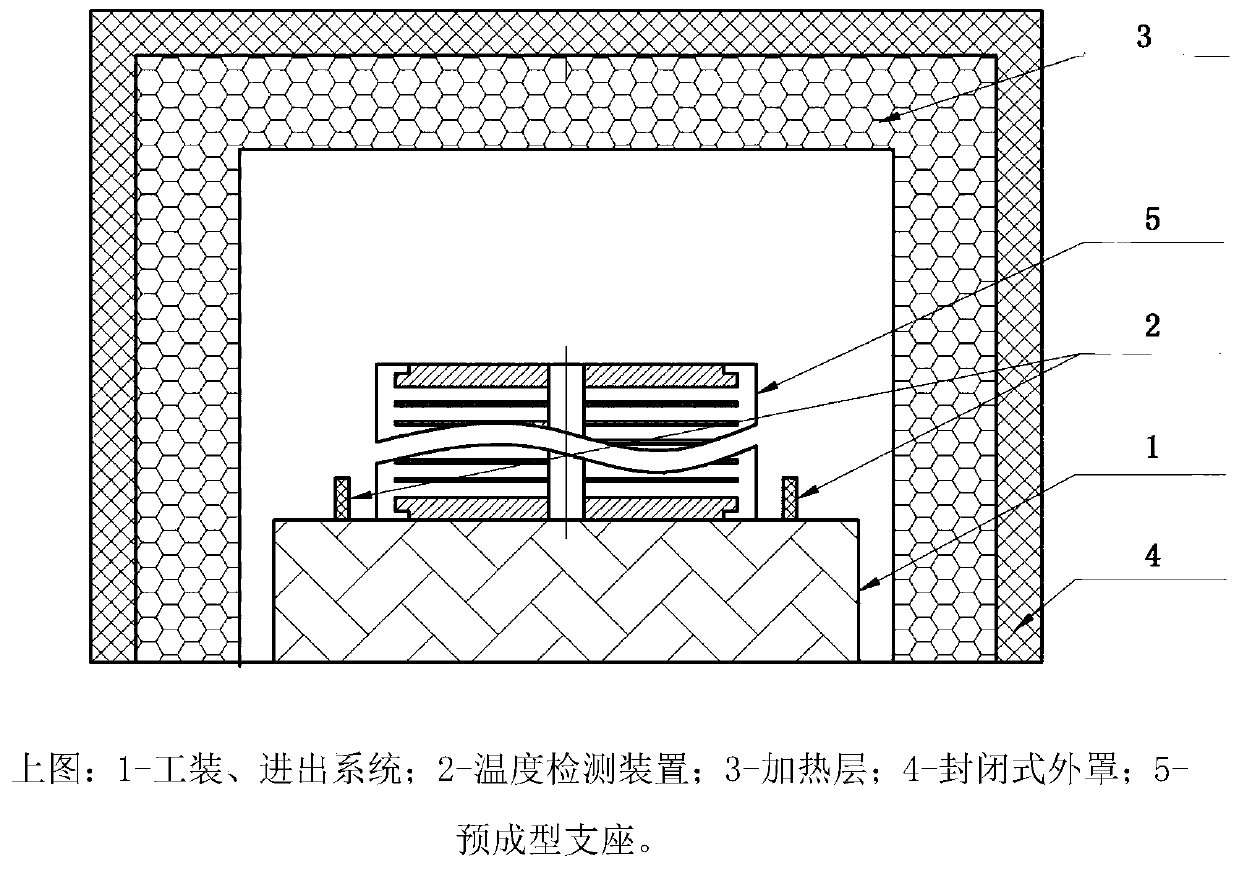

[0047]d) Put the semi-finished product to be molded into the heating device for preheating. After the preheating process is raised to 75°C-85°C at a speed of 5°C / min, the holding time is longer than 4h; the preset temperature upper limit is 85°C, according to the rubber The shear elastic modulus G value of the rubber is different, and the preheating time is different, but the preheating time is not less than 4 hours;

[0048] After the preheating time is reached, measure the temperature of the center of t...

Embodiment 1

[0059] A building shock-isolation rubber bearing, the preparation method comprising the steps of:

[0060] a) Preparation of rubber compound: prepare and process the rubber compound according to the following formula:

[0061] b) 100 parts of natural rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 2 parts of paraffin, 3 parts of anti-aging agent 4010NA, 1.5 parts of anti-aging agent, 1.5 parts of anti-aging agent RD, 1.5 parts of accelerator CZ, 1.5 parts of sulfur, 30 parts of N774 carbon black, 20 parts of aromatic oil; after masticating and kneading, a mixed rubber is formed; the masticating and kneading process is carried out according to the conventional method, and will not be repeated here.

[0062] c) Cut the steel plate according to the size requirements; the size requirements should be in accordance with the LNR-D1000 building isolation rubber bearing;

[0063] d) After the mixed rubber is rolled back and cut into pieces, the adhesive is bonded to the cut st...

Embodiment 2

[0070] A building shock-isolation rubber bearing, the preparation method comprising the steps of:

[0071] Preparation of rubber compound: prepare and process the rubber compound according to the following formula: the formula of the rubber compound described in step a) is as follows:

[0072] a) 100 parts of natural rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 1.5 parts of paraffin, 1.5 parts of flow exhaust agent CH236, 2 parts of anti-aging agent 4010NA, 1.5 parts of anti-aging agent RD, 1 part of anti-aging agent D, accelerator 1.5 parts of CZ, 0.8 parts of vulcanizing agent DTDM, 0.3 parts of vulcanizing agent PDM, 1.5 parts of sulfur, 30 parts of N774 carbon black, 15 parts of aromatic oil, 6.7 parts of liquid small molecule materials; after mastication and mixing, a compound rubber is formed; Wherein the masticating and mixing processes are carried out according to conventional methods, and details are not repeated here;

[0073] b) Cut the steel plate accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com