Laser perforating device with wide scanning focus

A laser drilling, wide-ranging technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems affecting the stability of handover, damage to the surface of cigarettes, adjustment quantity, etc., to achieve wide applicability, drilling The effect of high precision and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

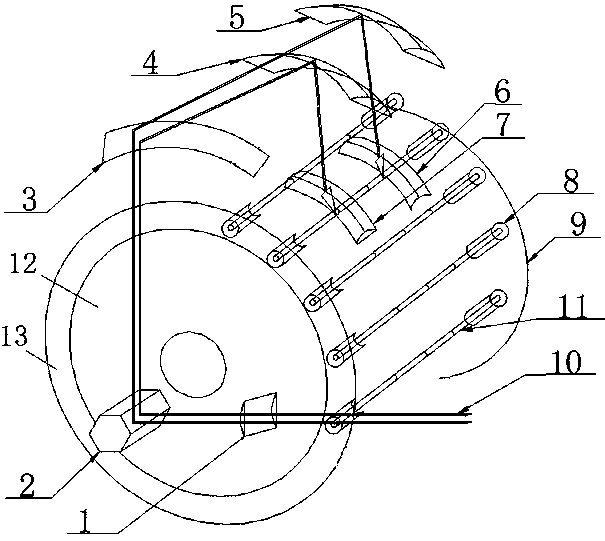

[0039] A wide-range scanning and focusing laser drilling device is composed of a floating conveying device and a laser drilling device.

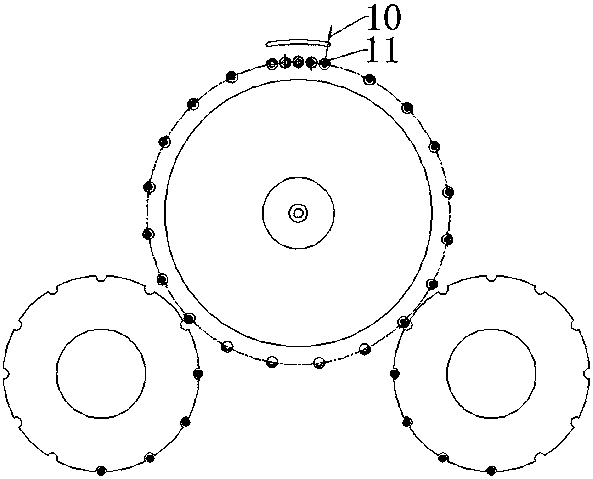

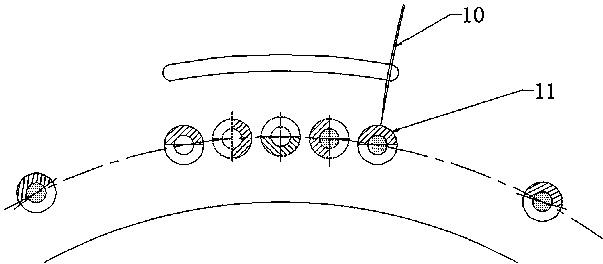

[0040] The main body of the floating conveying device is a rotating disk 9, and one end of the rotating disk 9 is provided with a power shaft, which drives the rotating disk 9 to rotate. A pair of runners 12 are looped between the two ends of the turntable 9, and a pair of shaft disks 13 are fixedly connected to the outer rings of the two ends of the turntable 9 between the runners 12; the cavity of the turntable 9 is provided with negative pressure suction The device communicates with the preset through holes on the shaft disc 13 through several negative pressure passages arranged between the shaft disc 13 and the inner cavity of the rotating disc 9. Preferably, the through holes are along the circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com