Vertical sawing machine

A sawing machine and vertical technology, which is applied in the direction of sawing machine, sawing machine accessories, metal sawing equipment, etc., can solve the problems of affecting the processing accuracy of sawing machine, poor processing accuracy, and insufficient stability of processing accuracy, and achieve enhanced clamping force Effect, improvement of cleaning efficiency, effect of increasing processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

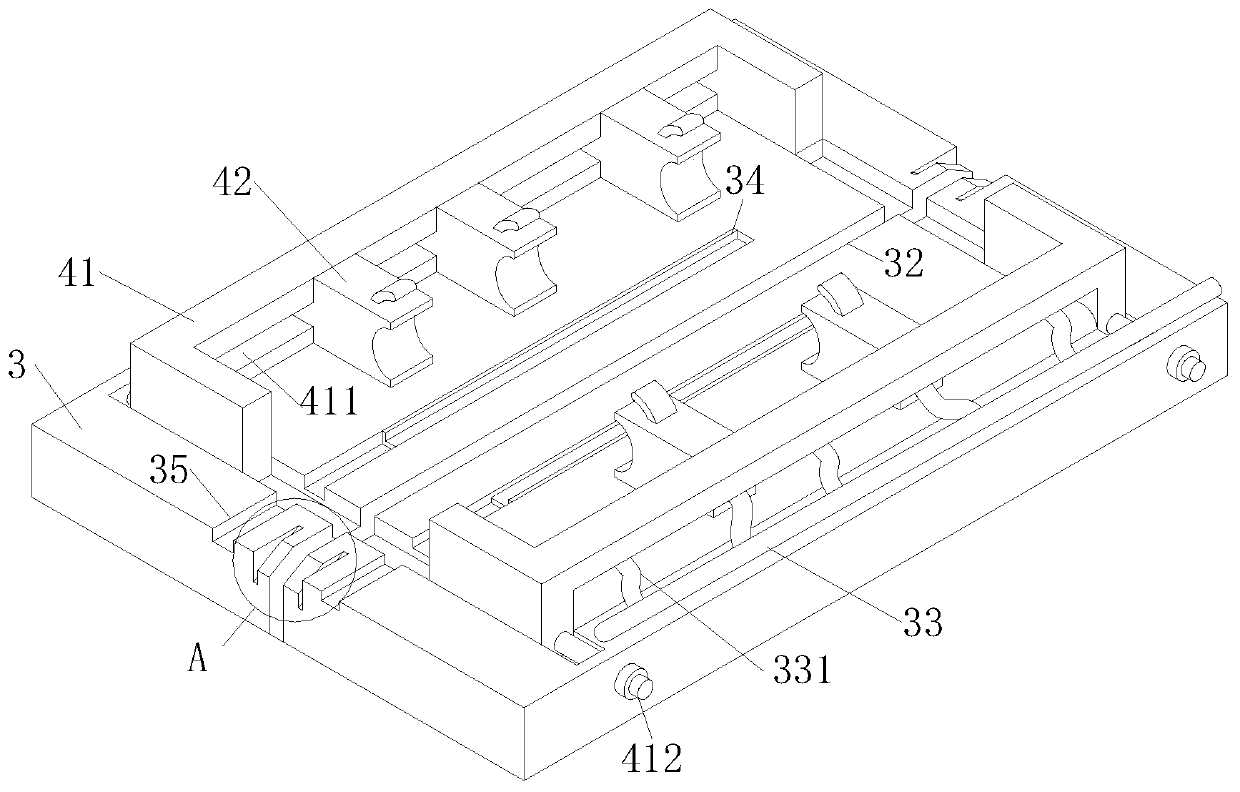

[0027] As an embodiment of the present invention, the tooling table 3 is provided with a baffle 34, and grooves 35 are provided on both sides of the saw groove 32 of the tooling table 3; the section of the baffle 34 is L-shaped, and the baffle 34 34 are symmetrically distributed on both sides of the tooling table 3 saw groove 32, the back below the baffle plate 34 is provided with a magnetic strip, the baffle plate 34 is fixed in the groove 35 on the tooling table 3, and the magnetic strip on the baffle plate 34 The sawdust scattered during sawing is collected by the suction; during work, the sawdust produced by the sawed workpiece will be scattered to the surface of the tooling table 3, and the set pressing block 42 moves on the clamping block 41 to adjust the clamping The tight position makes it difficult to clean up the sawdust scattered between the clamping block 41 and the pressing block 42. The baffle 34 is located on both sides of the saw groove 32, and the magnetic stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com