Solid-liquid mixed waste separating and crushing device and application thereof

A solid-liquid mixing and crushing device technology, applied in grain processing, presses, manufacturing tools, etc., can solve the problems of large area of solid-liquid separation structure, inability to cut solid residues effectively, and difficulty in subsequent processing, etc. The effect of subsequent transportation and processing, improving extrusion and crushing efficiency, and reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

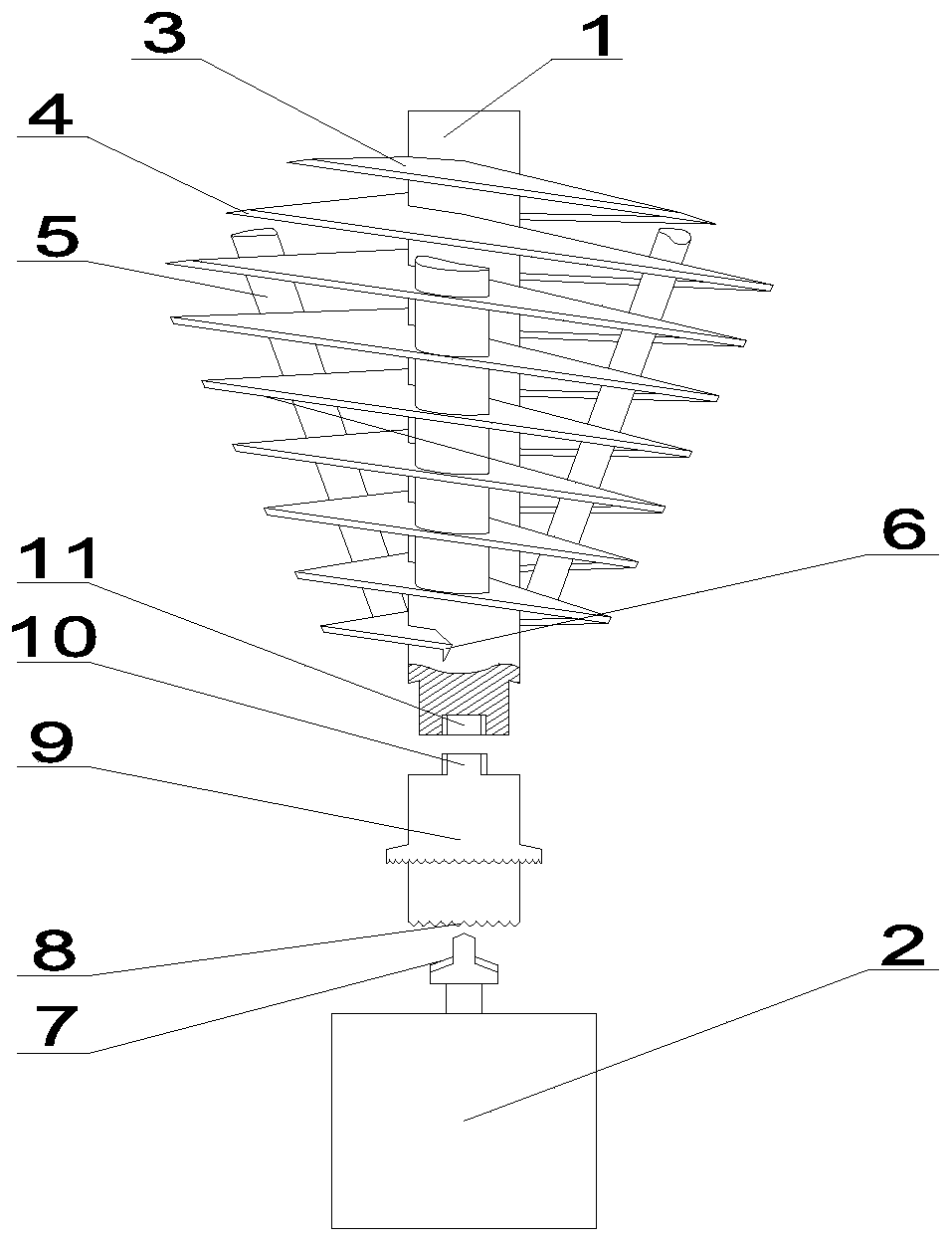

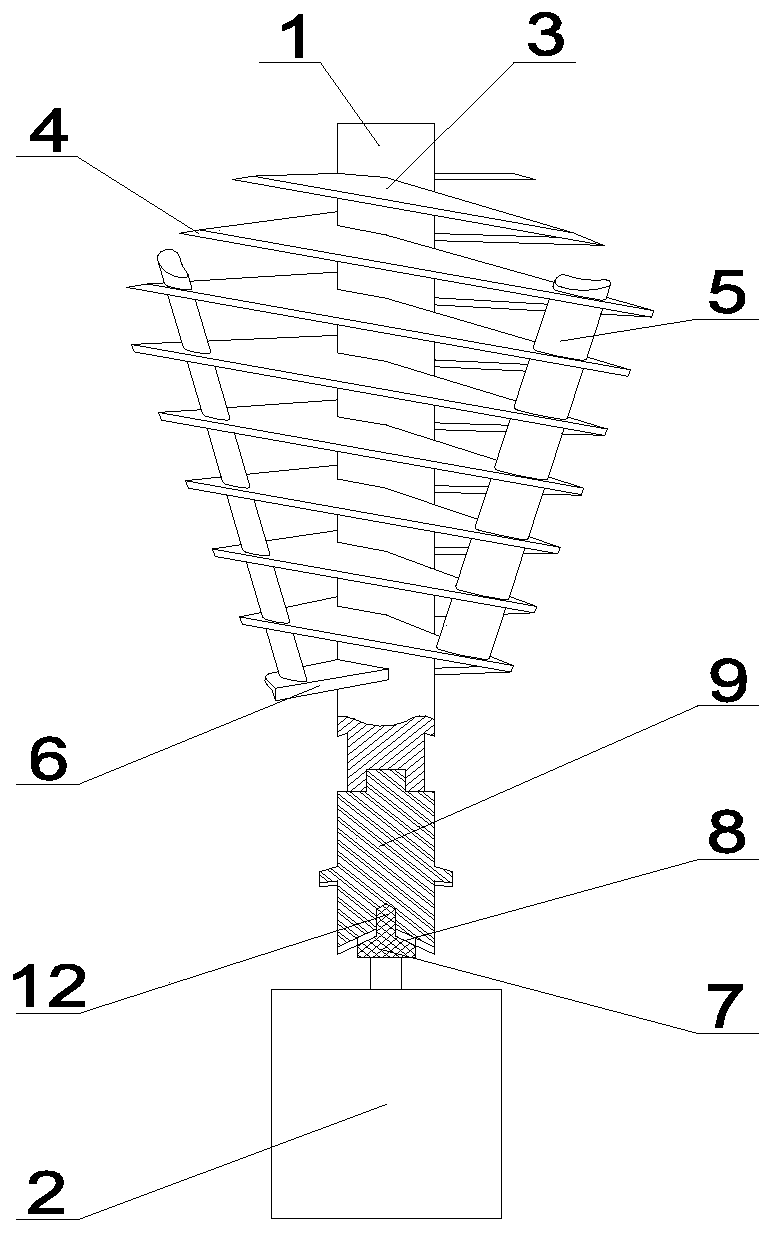

[0030] Embodiment 1: A solid-liquid mixed waste separation and crushing device

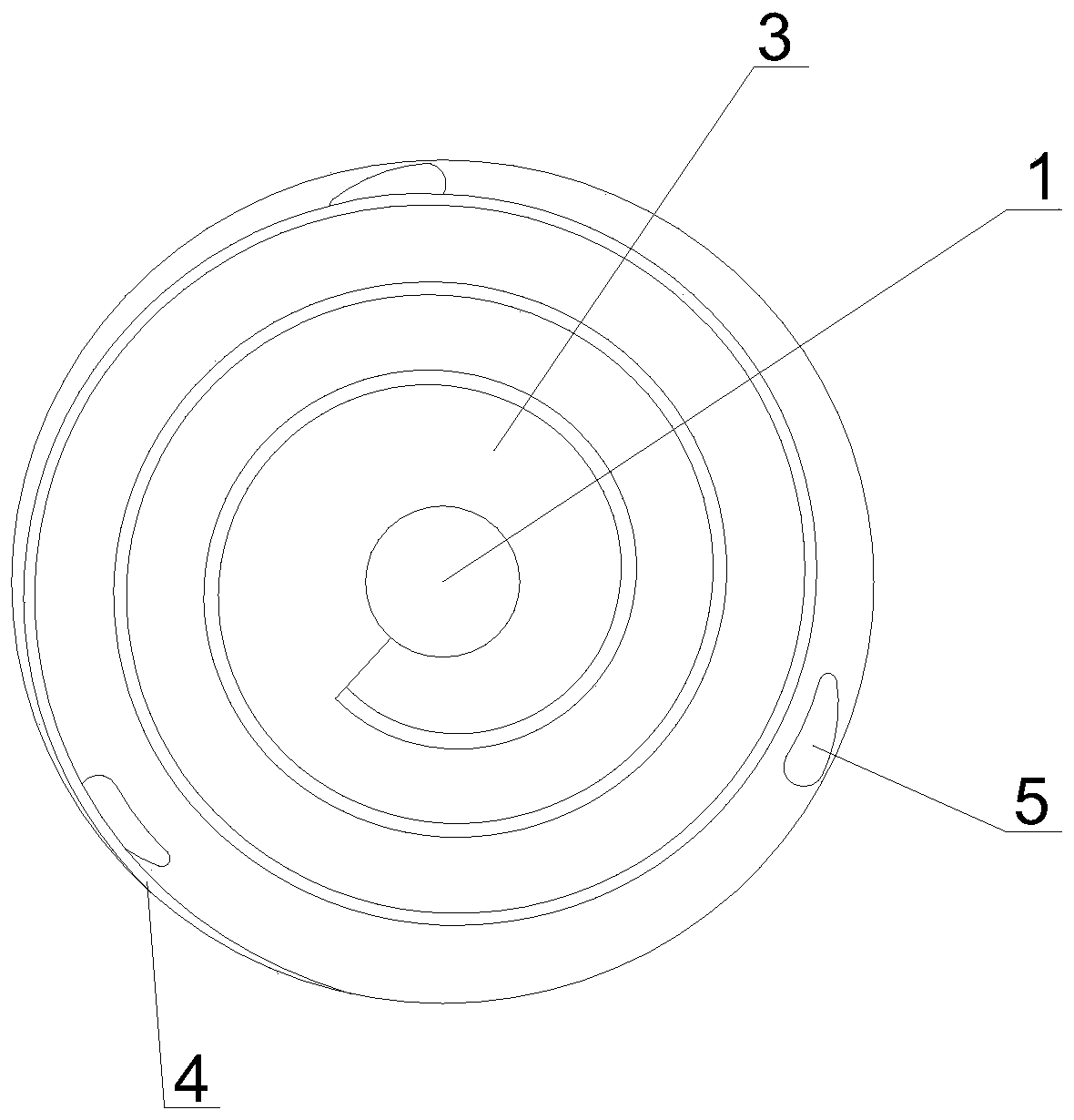

[0031] The invention provides a food waste separation and crushing device, which includes a screw shaft 1 and a motor 2. The motor 2 is arranged at the lower part of the screw shaft 1. The screw shaft 1 is provided with spiral blades 3 around the spiral blade 3 in a double cone structure. , The spiral blade 3 of the upper cone structure in the double cone structure is provided with knife edges 4 around.

[0032] In the present invention, the spiral blade 3 of the lower cone structure in the double cone structure is provided with a rotor column 5 in the middle, and the cross section of the rotor column 5 is the same as the wing cross section structure.

[0033] In the present invention, there are three or more rotor posts 5, the rotor posts 5 are symmetrically arranged around the screw shaft 1, and the direction of each rotor post 5 is the same.

[0034] In the present invention, a shearing plate 6 is prov...

Embodiment 2

[0041] Embodiment 2: Assembly of a solid-liquid mixed waste separation and crushing device

[0042] When assembling the food waste separation and crushing device of the present invention, the motor 2 is fixed at the bottom of a cone-shaped shell, the first bevel gear 7 extends into the shell, and the connecting shaft 9 is placed on the upper part of the motor 2 9 The screw shaft 1 is placed on the upper part, and the outer casing of the screw shaft 1 is in the shape of an inverted truncated truncated mesh structure. A filter screen is installed on the lower part of the screw shaft 1, and a shearing mechanism compatible with the shear plate 6 is welded on the filter screen.

Embodiment 3

[0043] Example 3: Application of a solid-liquid mixed waste separation and crushing device

[0044] When the food waste separation and crushing device of the present invention is applied, the waste is poured into the screw shaft 1 from the upper part. As the screw shaft 1 rotates, the waste is squeezed downwards. At the same time, the upper knife edge 4 will be larger. The garbage is shredded, and the rotor column 5 continuously throws out the garbage stuck in the middle. As the squeezing progresses, the massive garbage is squeezed and broken, and the long strips of garbage are cut by the knife edge 4, and all the garbage is downward. Squeeze, the sewage flows out from the mesh of the shell during extrusion. The size of the shell and the screw shaft 1 are matched to ensure the smooth progress of the extrusion. The connecting shaft 9 at the lower part of the screw shaft 1 and the bevel gear on the motor 2 It is convenient to install and clean, the whole device is stable and reliab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com