Fluidized bed reactor, application thereof and hydrocarbon oil desulfurization method

A fluidized bed reactor and reactor technology are applied in the fields of fluidized bed reactors and gasoline adsorption desulfurization, which can solve problems such as affecting the stable operation of the device and being unable to discharge the reactor, simplifying the structure design of the device, reducing the crushing effect, good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

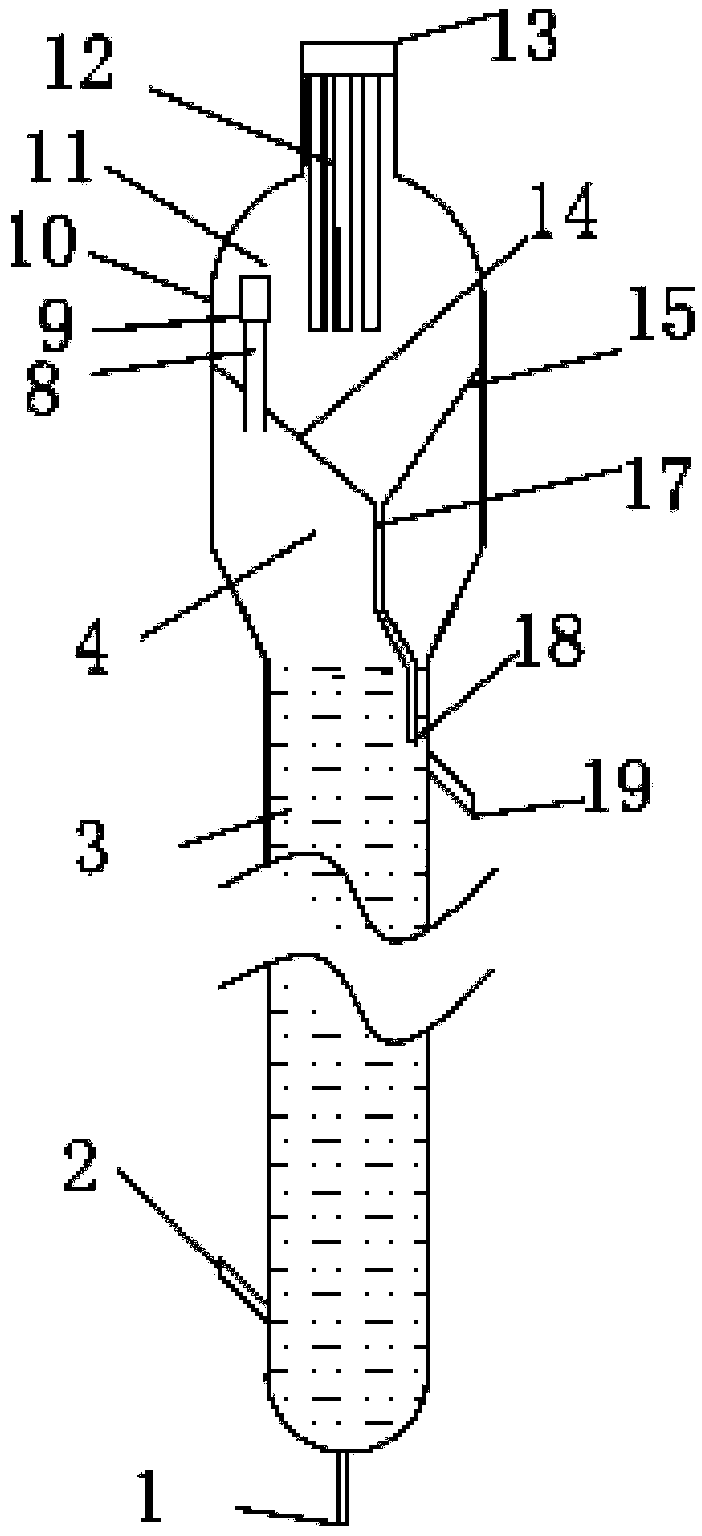

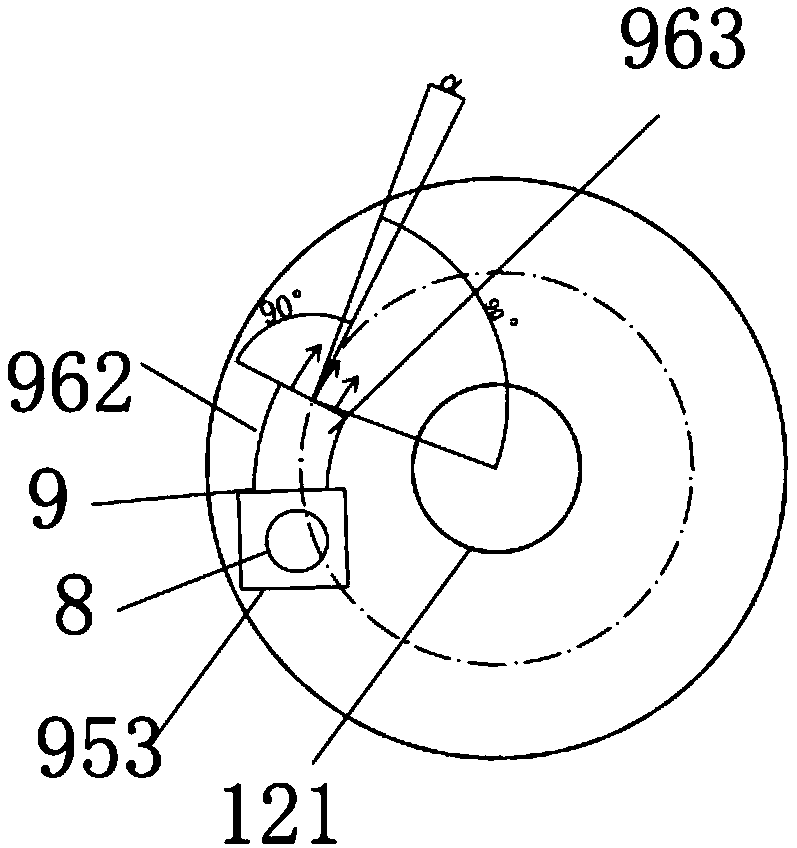

[0089] use as figure 1 The structure of the fluidized bed reactor shown is as follows: a partition member is provided in the settling zone of the reactor, the inclination angle of the baffle plate 15 is 60°, and the opening cross section of the partition member is circular. The upper part of the settling zone is equipped with a metal filter tube filter, and the lower space of the settling section is not equipped with a gas-solid separation device. There are two delivery pipes and fluid guiding structures entering the upper settling space, which are evenly distributed along the circumference, and the nozzle of the delivery pipe 8 protrudes from the partition member 14 at a distance of 200 mm. The height-to-width ratio of the outlet channel opening of the fluid-guiding structure is 3:1, the ratio of the radius of the outer wall of the outlet channel to the radius of the settlement area is 0.9, and the outlet normal direction of the outlet channel is in the radial direction of th...

Embodiment 2

[0096] Embodiment 2 adopts attached figure 1 The fluidized bed reactor shown is different from Example 1 in that the ratio of the outer edge radius R1 of the arc-shaped outlet channel to the upper space of the reactor settling section is 0.6, and the outlet normal direction of the outlet channel and the arc-shaped channel The included angle a of the circle tangent at the exit with the center of the radial section of the settlement space as the center is 8°, and the outer circumference of the exit channel is 600mm. The ratio of the cross-sectional area of the delivery pipe 8 to the cross-sectional area of the settlement zone is 0.025. The outlet gas velocity of the fluid guiding structure 9 is 6m / s.

[0097] Reaction method, sulfur-containing hydrocarbon oil raw material, reaction conditions are the same as embodiment 1.

[0098] The device runs continuously for 500 hours. During the reaction process, the following indicators were monitored: (1) filter pressure drop; (2)...

Embodiment 3

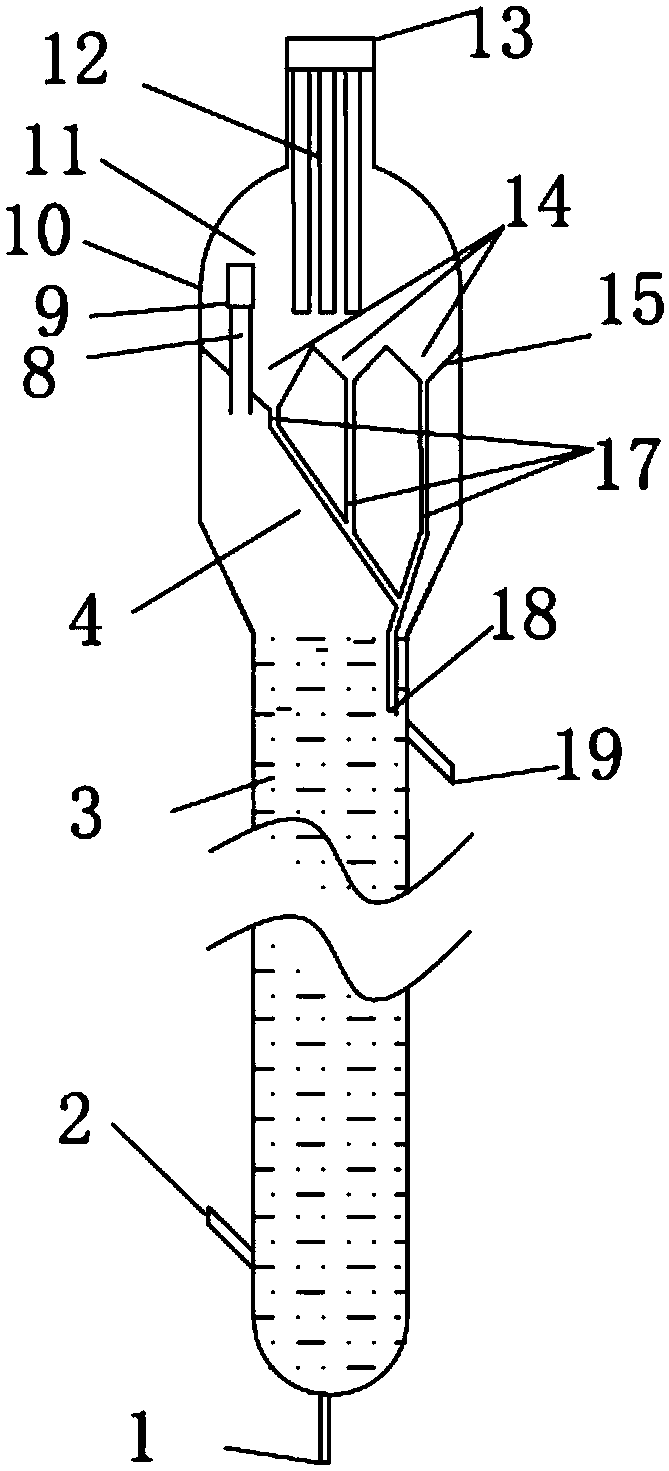

[0102] Embodiment 3 adopts as attached figure 2 In the fluidized bed reactor shown, the settling area of the reactor is provided with a partition member, the partition member is a quasi-conical shape formed by 9 small cones and its material legs, and the included angle between the dividing plate 15 and the horizontal plane constituting the partition member is 45°, the opening cross-section of each partition member is an irregular polygon. The upper part of the settling area is provided with a metal filter tube filter 13, and there are three conveying pipes and fluid guide outlet structures entering the upper settling space, which are evenly distributed along the circumference. The aspect ratio of the opening of the outlet channel of the fluid guide outlet structure 9 is 4:1, and the ratio of the radius of the surrounding plate outside the outlet channel to the radius of the settlement zone is 0.9. The angle a between the outlet normal of the arc-shaped outlet passage and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com