Drop ball forming device and oil ammonia column forming device

A molding device and drop ball technology, which is applied in chemical instruments and methods, liquid separation into beads and granulation, physical/chemical process catalysts, etc. Catalyst particle size and other issues, to achieve the effect of rapid replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

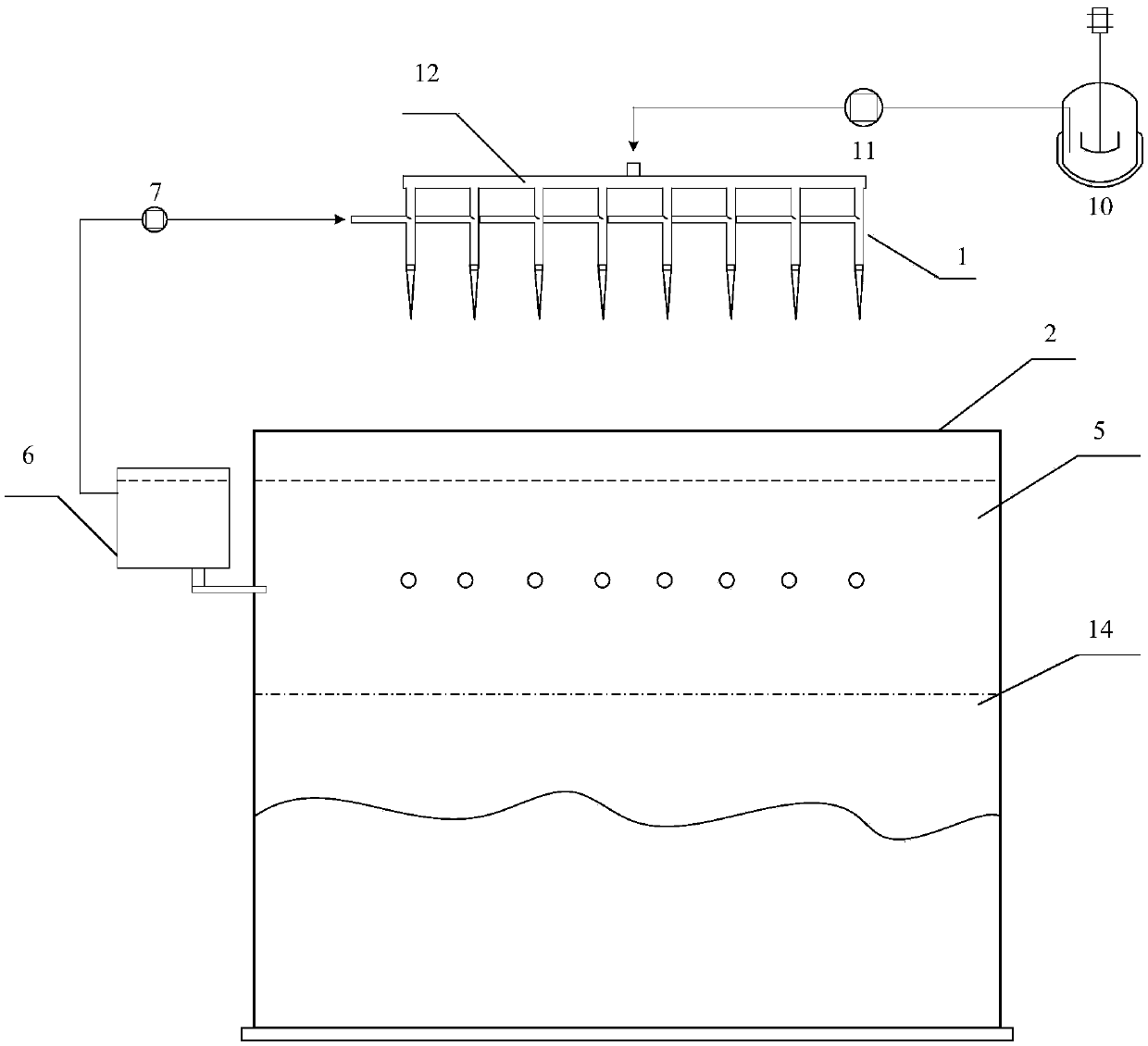

[0052] According to a preferred embodiment of the present invention, the drop ball forming device further includes: a horizontal tube distributor 12, which communicates with the outlet of the slurry tank 10 and the inlet of each slurry feed pipe 3 . The horizontal tube distributor 12 can ensure that the slurry feed volume of each dropper 1 is the same. Specifically, the inlet of the horizontal tube distributor 12 communicates with the outlet of the slurry tank 10, and the outlet of the horizontal tube distributor 12 communicates with the inlet of each slurry feeding pipe 3 respectively.

[0053] According to a specific embodiment of the present invention, a slurry pump 11 is provided on the pipeline connecting the inlet of the horizontal tube distributor 12 and the outlet of the slurry tank 10.

[0054] According to a specific embodiment of the present invention, the protective oil feed pipe 4 of each ball dropper 1 is connected in parallel with the pulse pump 7.

[0055] The drop ...

Embodiment 1

[0063] It is explained that the drop ball forming device and the oil ammonia column forming device provided by the present invention produce alumina carrier pellets.

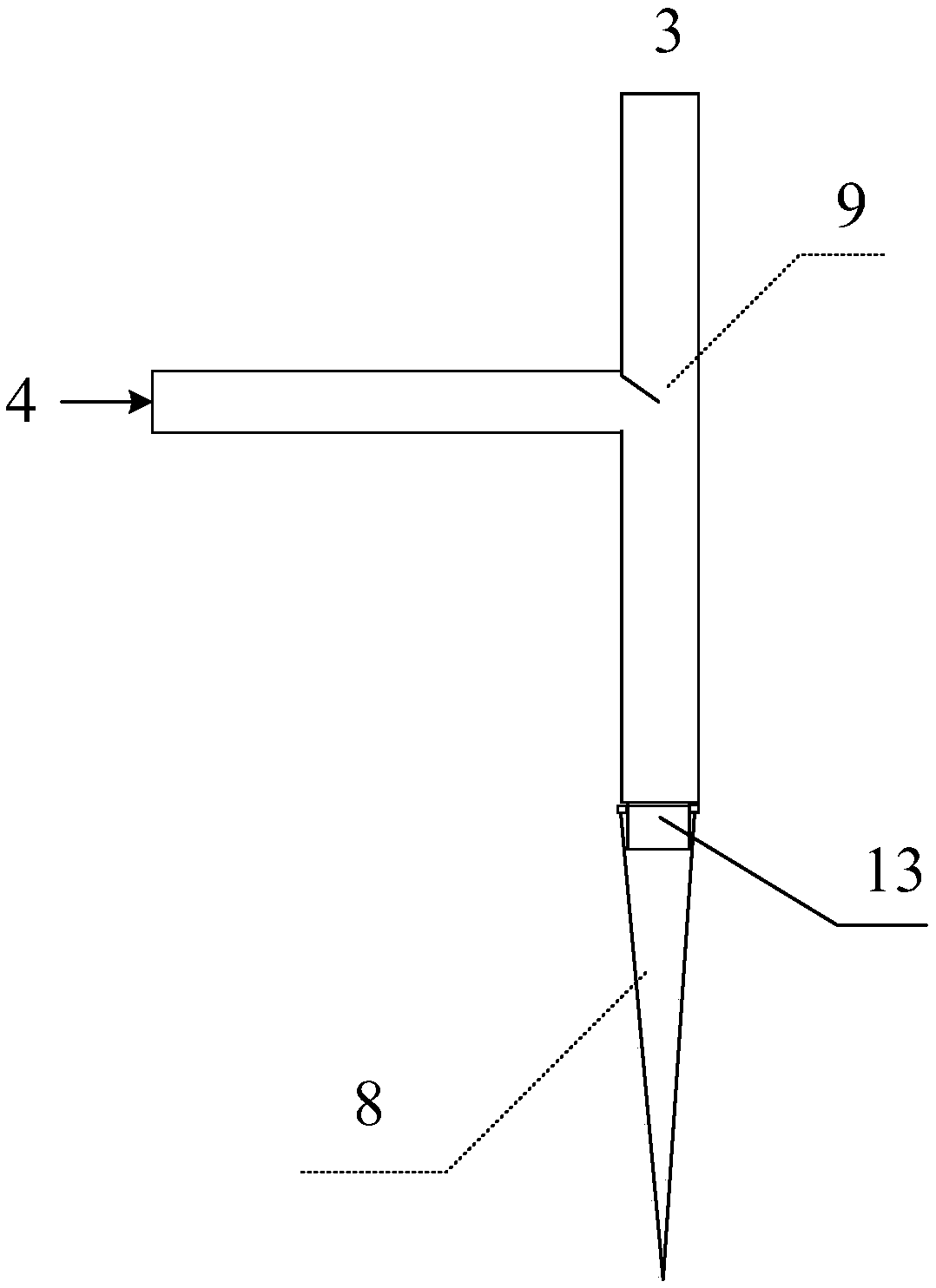

[0064] Such as figure 2 As shown, the dripping device includes 6 drippers 1 arranged side by side in parallel, the drippers 1 such as figure 1 As shown, it includes: a slurry feed pipe 3, a protective oil feed pipe 4 and a dripper 8; the slurry feed pipe 3 is set up vertically, and the protective oil feed pipe 4 is set horizontally. The inner diameter of the slurry feed pipe 3 is 5mm , The inner diameter of the protective oil feed pipe 4 is 5mm; the intersection of the slurry feed pipe 3 and the upper wall of the protective oil feed pipe 4 is provided with a guide plate 9, and one end (arc) of the guide plate 9 is welded to the slurry feed At the junction of the pipe 3 and the protective oil feed pipe 4, the width of the guide plate 9 is the same as the diameter of the slurry feed pipe 3. The guide plate 9 is arra...

Embodiment 2

[0072] It is explained that the drop ball forming device and the oil ammonia column forming device provided by the present invention produce molecular sieve-alumina pellets.

[0073] According to Example 1, the difference is that the slurry containing oxide particles: use HY molecular sieve and aluminum sol as raw materials to continuously produce HY-alumina pellets. The solid content of HY in the raw materials is 35% by weight, and the solid content of aluminum sol is 30% by weight, the molecular sieve and alumina sol are mixed at a mass ratio of 1:1 to form a slurry, and the solid content of the slurry is 25% by weight to prepare HY-alumina pellets (alumina: HY weight ratio is 1:1) .

[0074] During the whole dripping process, the dripper did not appear to stick, and there were no sticking small balls. The prepared HY-alumina pellets have good sphericity and uniform particle size, the particle size of the pellets is about 1.6 mm, the bulk density is 0.6 g / ml, and the crushing st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com