Device and method for adjusting deflector angle of scr reactor

An SCR reactor and angle adjustment technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problem that the SCR reactor cannot be adjusted according to the working conditions, so as to reduce the phenomenon of boundary layer separation, reduce the adjustment time, The effect of reducing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

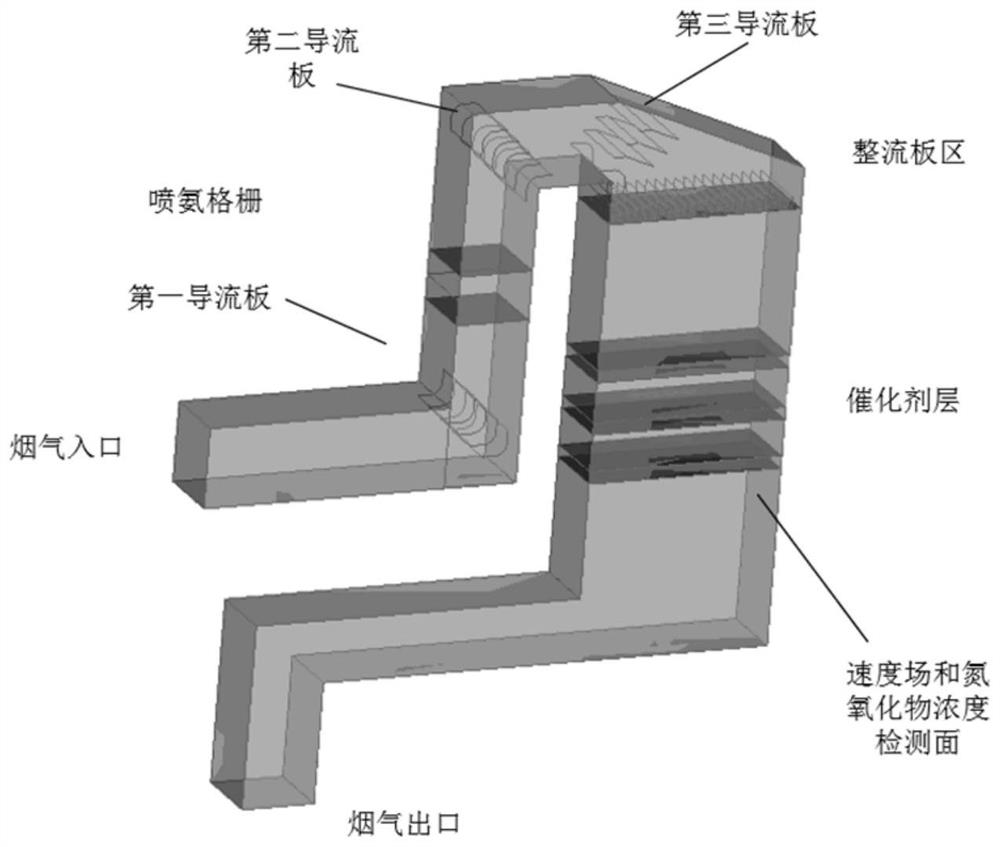

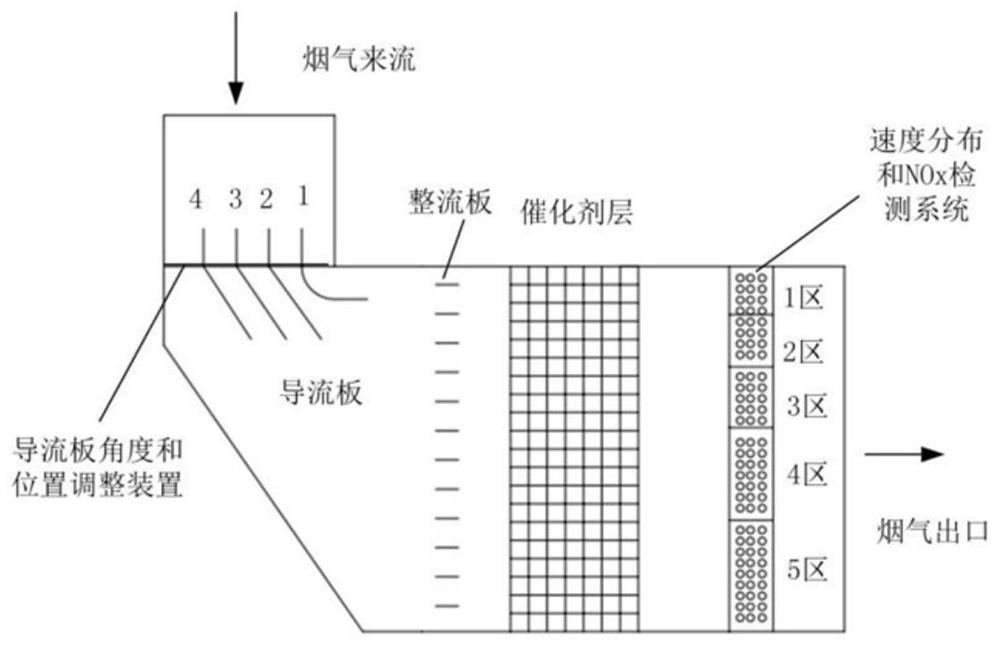

[0046] Such as figure 1 Shown is a schematic structural diagram of an SCR deflector adjusting device, in which a first deflector, a second deflector and a third deflector are sequentially arranged at three bends of the SCR reactor flue; The deflectors are all arranged at the geometric center of the curve; the area between the first deflector and the second deflector is provided with an ammonia injection grid; the area between the third deflector and the flue gas outlet is provided with a catalyst layer; A number of rectifying plates are arranged above the uppermost catalyst layer, and a nitrogen oxide detection system and a velocity measurement system are arranged below the lowermost catalyst layer;

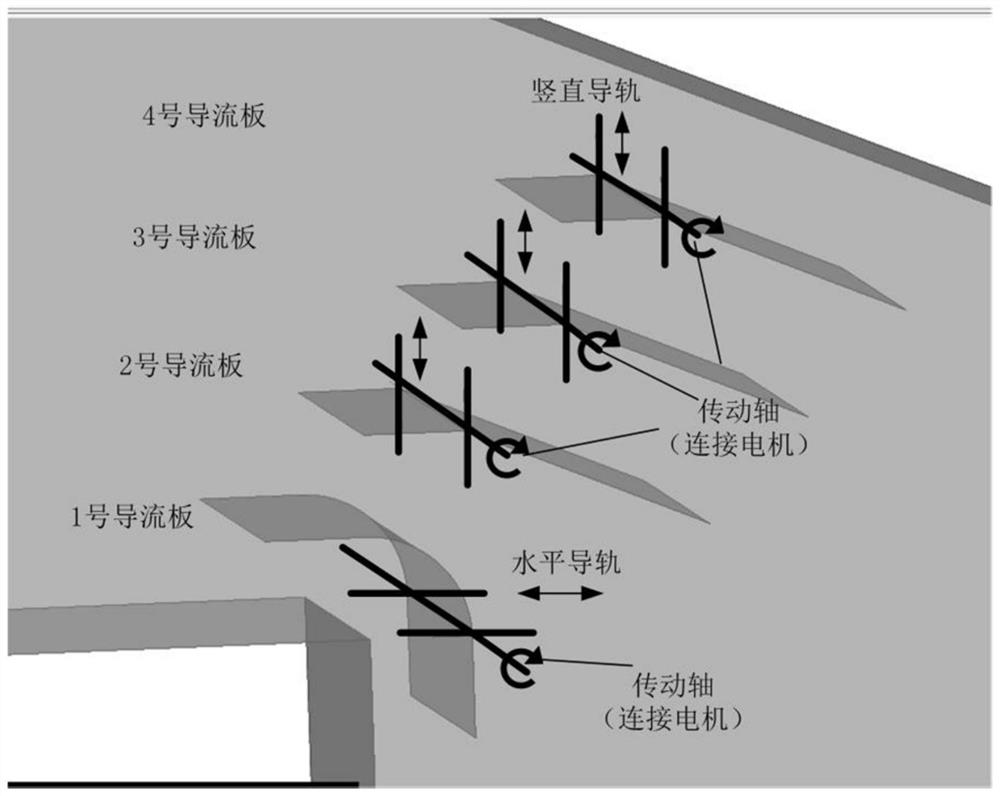

[0047] Such as figure 2 Shown is a schematic diagram of the angle adjustment structure and the position adjustment structure in the third deflector, such as image 3 Shown is a partially enlarged schematic diagram of the third deflector. Each deflector of the third deflector ...

Embodiment 2

[0066] This embodiment provides a method for optimizing the adjustment strategy of the deflector based on CFD. Provide basis for structure adjustment and relative position adjustment of deflector, such as Image 6 with Figure 7 Shown are the flow chart of the method for adjusting the SCR deflector and the flow chart of computational fluid dynamics (CFD) simulation, respectively. The method comprises the steps of:

[0067] Optimize the structural parameters of the deflector through fluid dynamics (CFD) calculations;

[0068] Construct the physical model and grid model of the SCR reactor and the deflector according to the structural parameters and basic shape of the deflector;

[0069] The parameters of the actual operating conditions are input into the solver, and the velocity field distribution of the SCR reactor is simulated by numerical calculation.

[0070] Take the typical flue gas composition as an example as the boundary condition: the outlet flue gas composition is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com