Sedimentation tank and combined shaped sedimentation tank thereof

A technology of sedimentation tank and steel plate, applied in the direction of sedimentation tank, etc., can solve the problems of poor sewage treatment, and achieve the effect of simple and reliable structure, improved construction efficiency and convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

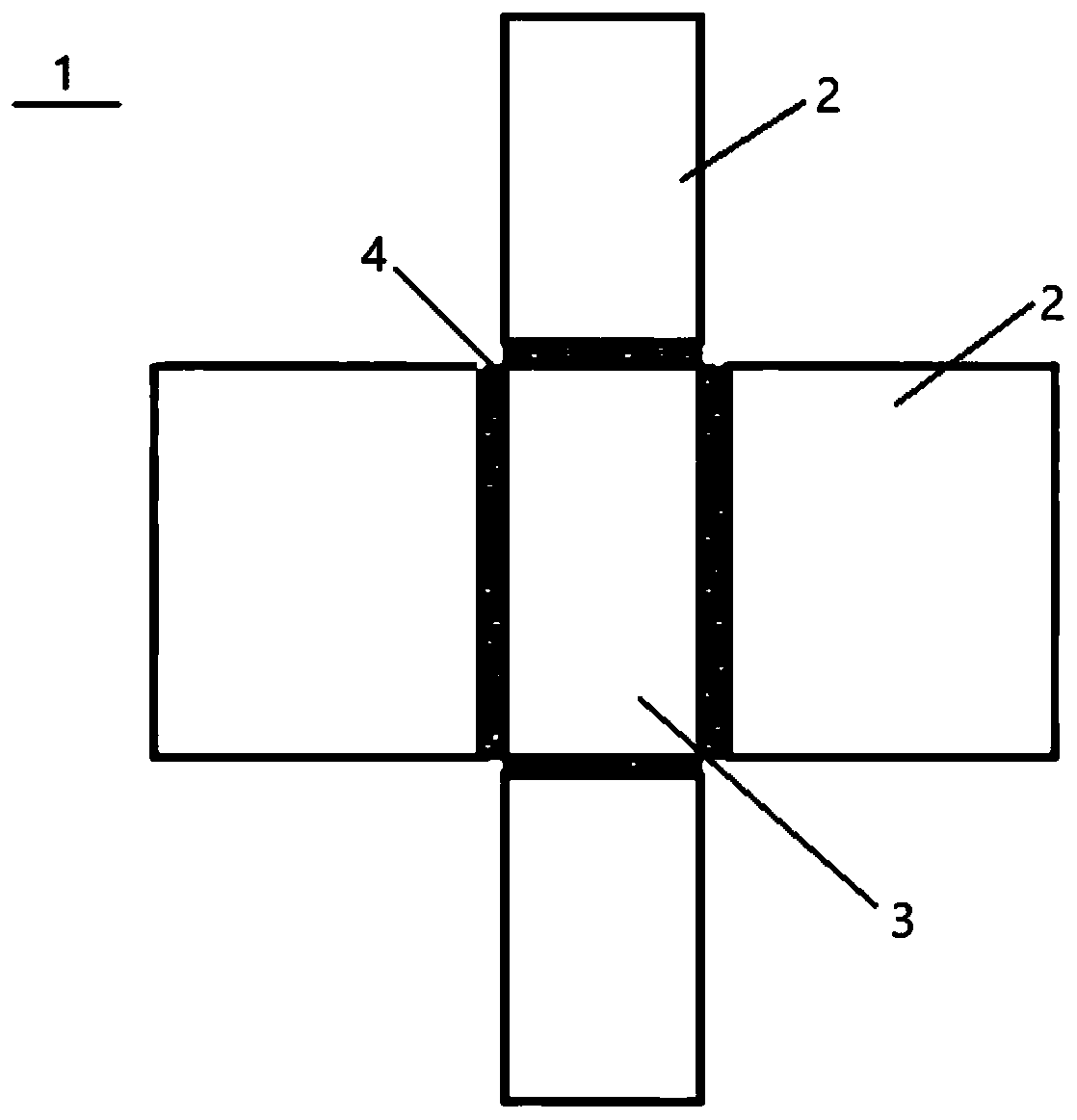

[0014] Such as figure 1 As shown, the sedimentation tank 1 includes four facade steel plates 2 and bottom steel plates 3, and the extension welds 4 are formed between the four facade steel plates 1 and the bottom steel plates 3, which are welded into a hollow rectangular tube, and the open end of the rectangular tube is connected to the The bottom steel plate is welded into a container, and the facade steel plate and the bottom steel plate are 20mm thick steel plates.

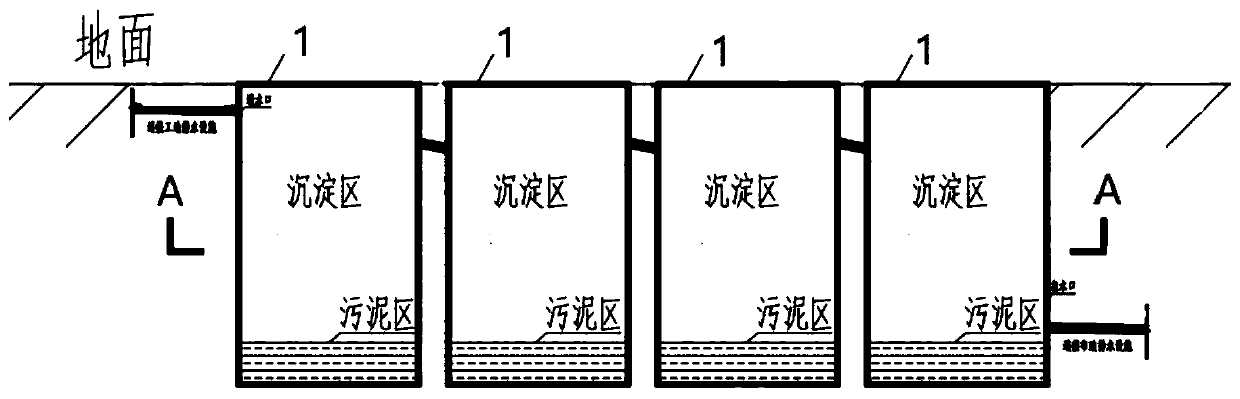

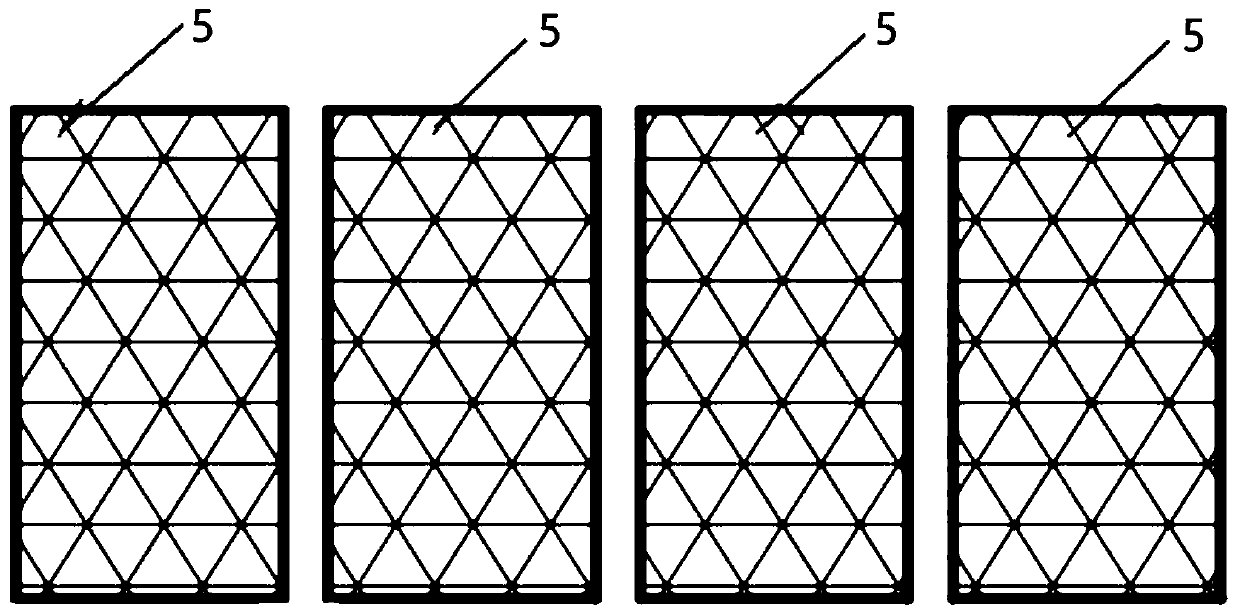

[0015] Such as figure 2 As shown in -4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com