Liquid level measuring device based on capacitive sensor

A technology of capacitive sensor and liquid level measuring device, which is applied in the direction of measuring device, liquid/fluid solid measurement, and liquid level indicator for physical variable measurement, etc. It solves the problems of normal filling, transportation and use of tanks, and achieves the effect of less leads, good engineering practical value and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

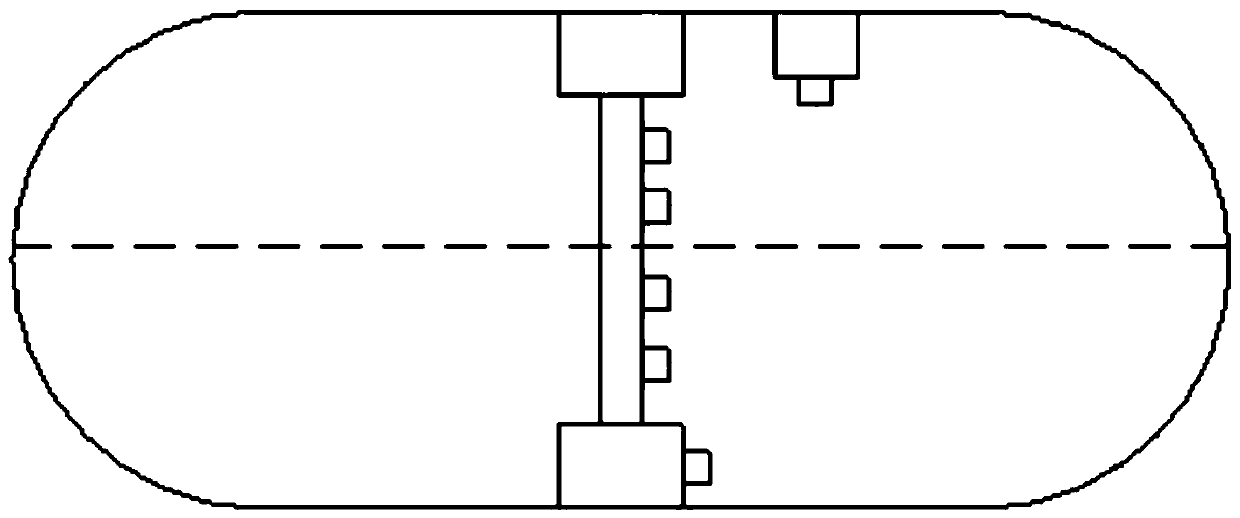

[0016] like figure 1 A liquid level measurement device based on a capacitive sensor is shown, the capacitive detection unit is provided with multiple capacitive sensors for detecting the liquid level in the storage tank, and there are liquid level detection points at different vertical heights A liquid level capacitive sensor for real-time capacitive data detection; an initialization unit, which initializes the capacitance when no-load and the capacitive value when it is full; Measurement, from which the state of the current fixed-point liquid level can be obtained, and whether the liquid has reached the liquid level at the fixed point is judged; at the same time, a capacitive sensor for detecting gas is installed on the top of the tank, and the capacitance in the gas increases with the LNG liquid level in the sensor according to statistics. For the change curve, the capacitance value measured by the capacitive sensor for detecting gas is used to assist in calculating the heig...

Embodiment 2

[0022] This embodiment discloses a liquid level measuring device based on a capacitive sensor. The capacitive detection unit is provided with a plurality of capacitive sensors for detecting the liquid level in the storage tank. A liquid level capacitive sensor for real-time capacitive data detection; an initialization unit, which initializes the capacitance value when no-load and full load; the control chip unit, which controls the multiple capacitive sensors described in the tank environment capacitance data From this, the state of the current fixed-point liquid level can be obtained, and whether the liquid has reached the liquid level at the fixed point can be judged to measure the height of the current liquid level.

[0023] Furthermore, the capacitive sensor is provided with a sensitivity adjustment capacitor for adjusting detection sensitivity.

[0024] Furthermore, the power supply unit used for the capacitive sensor is a rectification and voltage stabilization circuit. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com