Preparation method of high-Tc low-resistance lead-free PTC material

A thermistor and positive temperature coefficient technology, which can be applied to resistors with positive temperature coefficient and other directions, which can solve problems such as increasing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] By 0.04(Bi 1 / 2 Na 1 / 2 )TiO 3 -yCaTiO 3 -(0.96-y)BaTiO 3 +0.165mol%Nb 2 o 5 +0.167mol% Al 2 o 3 +1.0mol%TiO 2 +0.2mol% Li 2 CO 3 Carry out batching, wherein y=0.02, 0.04, 0.06, 0.08, 0.10, 0.12, 0.14, 0.16, 0.18, 0.20, weigh after calculating the weight according to the molar ratio in the molecular formula, the weighing quality is as follows in Table 1:

[0021] Table 1. Ingredients list one (unit: g)

[0022] Numbering BNT BaTiO 3

CaTiO 3

Nb 2 o 5

al 2 o 3

TiO 2

Li 2 CO 3

B4-C-00 8.4740 223.8645 0 0.4386 0.1703 0.7987 0.1478 B4-C-02 8.4740 219.2007 2.7189 0.4386 0.1703 0.7987 0.1478 B4-C-04 8.4740 214.5368 5.4377 0.4386 0.1703 0.7987 0.1478 B4-C-06 8.4740 209.8730 8.1566 0.4386 0.1703 0.7987 0.1478 B4-C-08 8.4740 205.2091 10.8755 0.4386 0.1703 0.7987 0.1478 B4-C-10 8.4740 200.5453 13.5944 0.4386 0.1703 0.7987 0.1478 B4-C-12 8.4740...

Embodiment 2

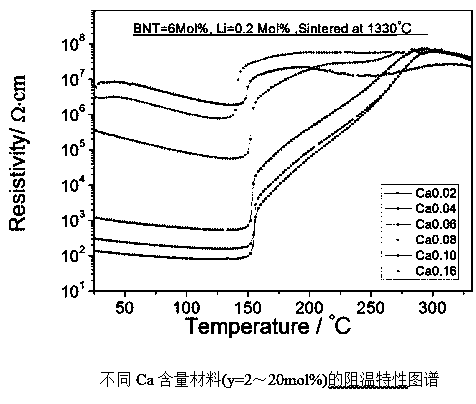

[0028] By 0.06(Bi1 / 2 Na 1 / 2 )TiO 3 -yCaTiO 3 -(0.94-y)BaTiO 3 +0.165mol%Nb 2 o 5 +0.167mol%Al 2 o 3 +1.0mol%TiO 2 +0.2mol%Li 2 CO 3 Carry out batching, y=0.02, 0.04, 0.06, 0.08, 0.10, 0.12, 0.14, 0.16, 0.18, 0.20, weigh after calculating the weight according to the molar ratio in the molecular formula, the weighing quality is as follows Table 3:

[0029] Table 3. Ingredients List II (unit: g)

[0030]

[0031]

[0032] Weigh according to the formula in ingredient list 2, pre-synthesize BNT, CaTiO 3 Then add BaTiO in proportion 3 , Nb 2 o 5 、Al 2 o 3 、TiO 2 , Li 2 CO 3 , using agate balls and deionized water as the medium, ball milling for 24 hours, adding 8wt% polyvinyl alcohol (PVA) with a concentration of 10wt% to the dried powder to granulate, and pressing a Φ10×2.0mm disc with a pressure of 10MPa , hold the pressure for 15s, sinter the pressed disc in the air atmosphere, the sintering temperature is 1330°C, and keep it at this temperature for 10min...

Embodiment 3

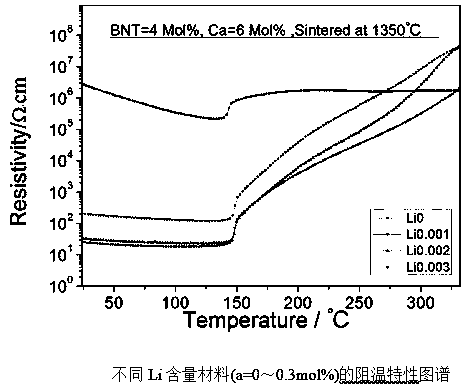

[0037] By 0.04(Bi 1 / 2 Na 1 / 2 )TiO 3 -0.06CaTiO 3 -0.90BaTiO 3 +aLi 2 CO 3 +0.165 mol% Nb 2 o 5 +0.167mol%Al 2 o 3 +1.0mol%TiO 2 Carry out batching, wherein a=0~0.003, weigh after calculating the weight according to the molar ratio in the molecular formula, the weighing quality is as follows Table 5:

[0038] Table 5. Ingredients list three (unit: g)

[0039] Numbering BNT BaTiO 3

CaTiO 3

Nb 2 o 5

al 2 o 3

TiO 2

Li 2 CO 3

L-00 8.4740 209.8730 8.1566 0.4386 0.1703 0.7987 0 L-01 8.4740 209.8730 8.1566 0.4386 0.1703 0.7987 0.0739 L-02 8.4740 209.8730 8.1566 0.4386 0.1703 0.7987 0.1478 L-03 8.4740 209.8730 8.1566 0.4386 0.1703 0.7987 0.2217

[0040] Weigh according to the formula in ingredient list 3, pre-synthesize BNT, CaTiO 3 Then add BaTiO in proportion 3 , Nb 2 o 5 、Al 2 o 3 、TiO 2 , Li 2 CO 3 , using agate balls and deionized water as the medium, ball mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com