Production process of decorative material for granular ceramic blank

A decorative material and production process technology, applied in the field of decorative materials, can solve the problems of easy wear of the decorative layer, affect the decorative effect, and lose decorativeness, etc., and achieve the effect of not easy to fade, natural decorative effect, and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

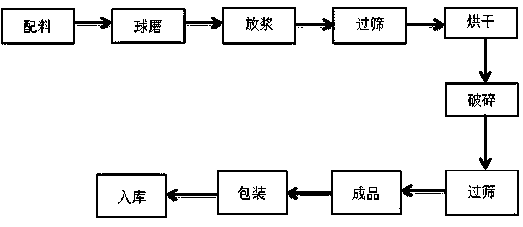

Method used

Image

Examples

Embodiment 1

[0031] Mix 60% feldspar powder, 18% quartz powder, 18% clay powder, and 9% calcium carbonate powder and put them into a ball mill, then add water for wet grinding, and add 2 parts of binder before the grinding is completed to obtain The glaze slurry whose viscosity range is controlled between 4.2pa.s; release the glaze slurry in a ball mill, use a 75-mesh vibrating screen for vibration screening, and then put it into a mixing bucket at room temperature for stirring treatment; use a glaze slurry distribution machine to The glaze slurry after stirring treatment is evenly coated on the belt of the dryer, the thickness is controlled at 2.0mm, and then dried by the dryer to form a large particle glaze, the drying time is 60min, and the drying temperature is 160°C; put the dried large-grained glaze into the low-vibration split device for crushing, and then pass through the 8-mesh vibrating sieve for granular glaze screening, and collect the granular glaze that passes through the 8-me...

Embodiment 2

[0033] Mix 50% feldspar powder, 15% quartz powder, 20% clay powder, and 10% calcium carbonate powder and put them into a ball mill, then add water for wet grinding, and add 2 parts of binder before the grinding is completed to obtain The glaze slurry whose viscosity range is controlled between 4.0pa.s; release the glaze slurry in a ball mill, use an 80-mesh vibrating screen for vibration screening, and then put it into a mixing bucket at room temperature for stirring treatment; use a glaze slurry distributing machine to The glaze slurry after stirring treatment is evenly coated on the belt of the dryer, the thickness is controlled at 1.5mm, and then dried by the dryer to form a large particle glaze, the drying time is 65min, and the drying temperature is 180°C; put the dried large-grained glaze into the low-vibration split equipment for crushing, and then pass through a 6-mesh vibrating sieve for granular glaze screening, and collect the granular glaze that passes through the 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com