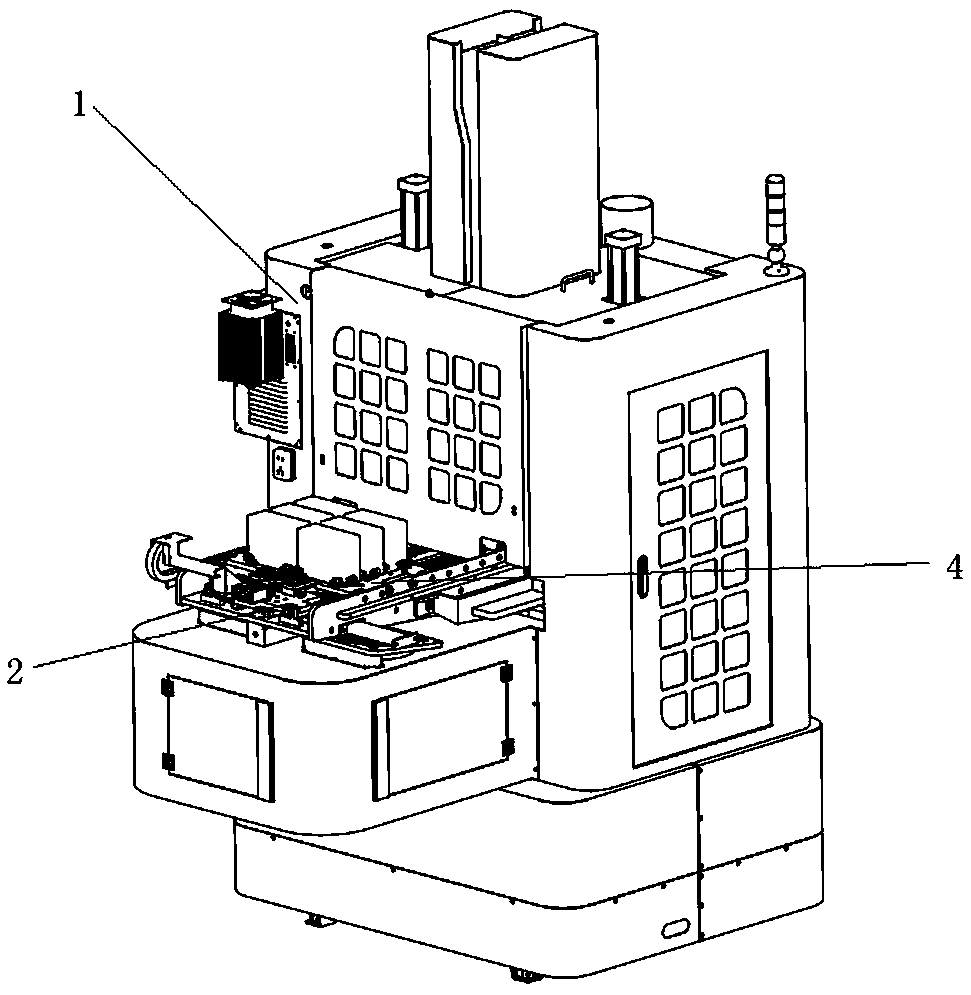

Full-automatic casting and welding machine and automatic casting and welding assembly line

A casting and welding machine and fully automatic technology, applied in the field of automatic casting and welding machines and automatic casting and welding lines, can solve the problems of low production efficiency of casting and welding machines, lowering of casting and welding quality, easy generation of lead slag, etc., and achieve good universal use. performance, reducing the formation of impurities and saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

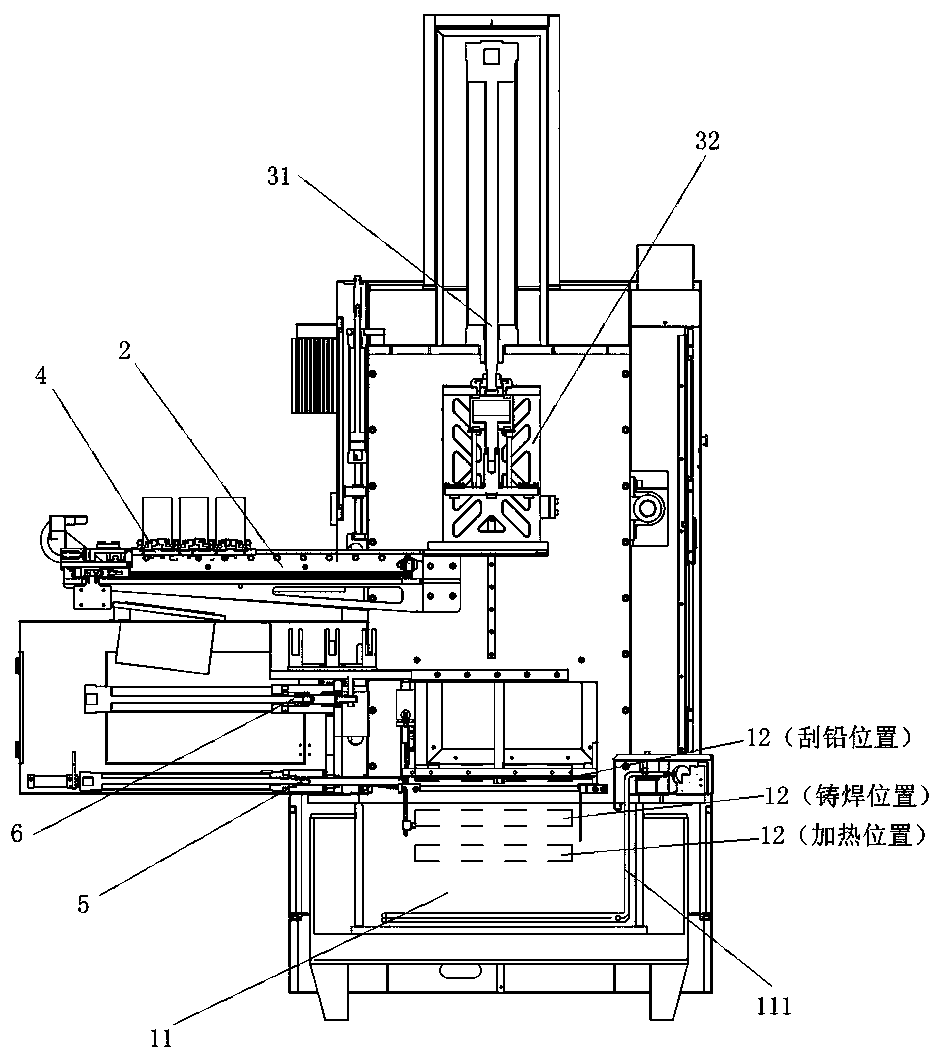

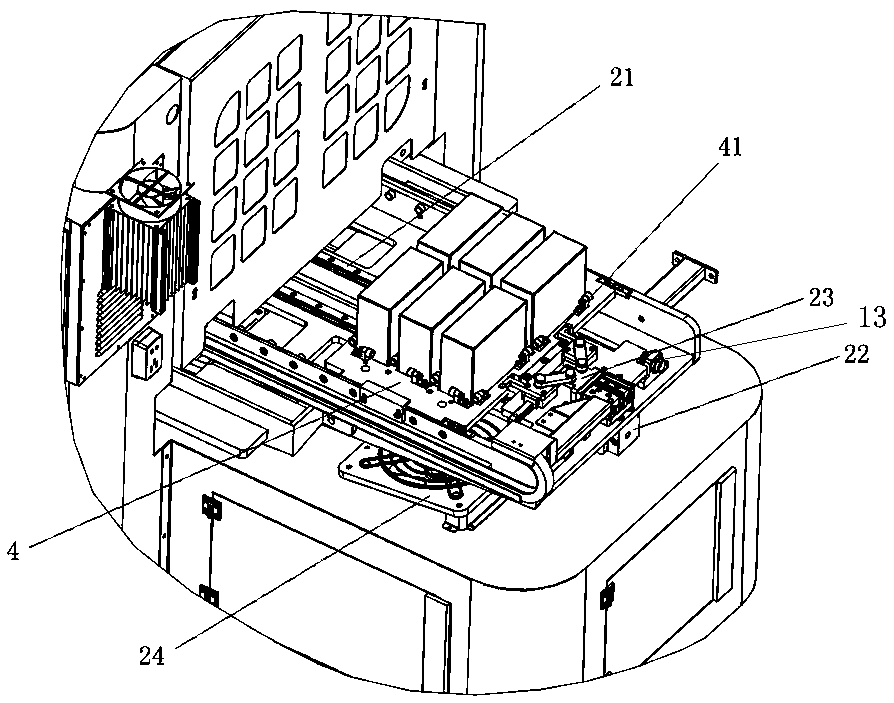

Examples

Embodiment 2

[0042] like Figure 6 As shown, Embodiment 2 provides an automatic casting and welding assembly line, so as to realize the automatic operation of the battery cluster casting and welding process, which includes a fully automatic casting and welding machine described in Embodiment 1, and also includes The feeding platform 71, the brush cutting machine 72, the clamping station 73, the turning and blanking station 74 and the conveying line are set in sequence in the downstream, and the feeding assembly 2 of the automatic casting welding machine is located at the clamping station 73 and the turning and blanking station Between 74, there is also a multi-mode gripper 75 for clamping the battery cluster. The multi-mode gripper 75 is movably arranged between the clamping station 73, the turning and unloading station 74 and the feeding assembly 2. The multi-mode gripper 75 is a gripper structure composed of a plurality of frames corresponding to the positions of the battery clusters pla...

Embodiment 3

[0046] The technical solution recorded in the third embodiment is similar to that of the first embodiment, the difference is that:

[0047] In this embodiment, the multi-mode gripper 75 is connected to the end of an industrial six-axis manipulator with a single-arm structure commonly used in the industry, so that the multi-directional movement provided by the multi-axis manipulator makes the stations and machinery of each upstream assembly line Compared with Embodiment 2, it can be arranged more freely (as long as the clamping station, the turning and unloading station and the feeding assembly of the automatic casting and welding machine are within the operating range of the manipulator). Therefore, it has better convenience of assembly line production, reduces the demand for production sites, and improves versatility.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com