Wood block surface cleaning and counting device

A surface cleaning and counting device technology, applied in cleaning methods and utensils, counting mechanisms/items, cleaning methods using tools, etc., can solve the problems of easy stacking, inaccurate transmission positions, and inaccurate counting, etc., to reduce cleaning Dead angle, improve cleaning effect, and expand the effect of cleaning range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0019] Example.

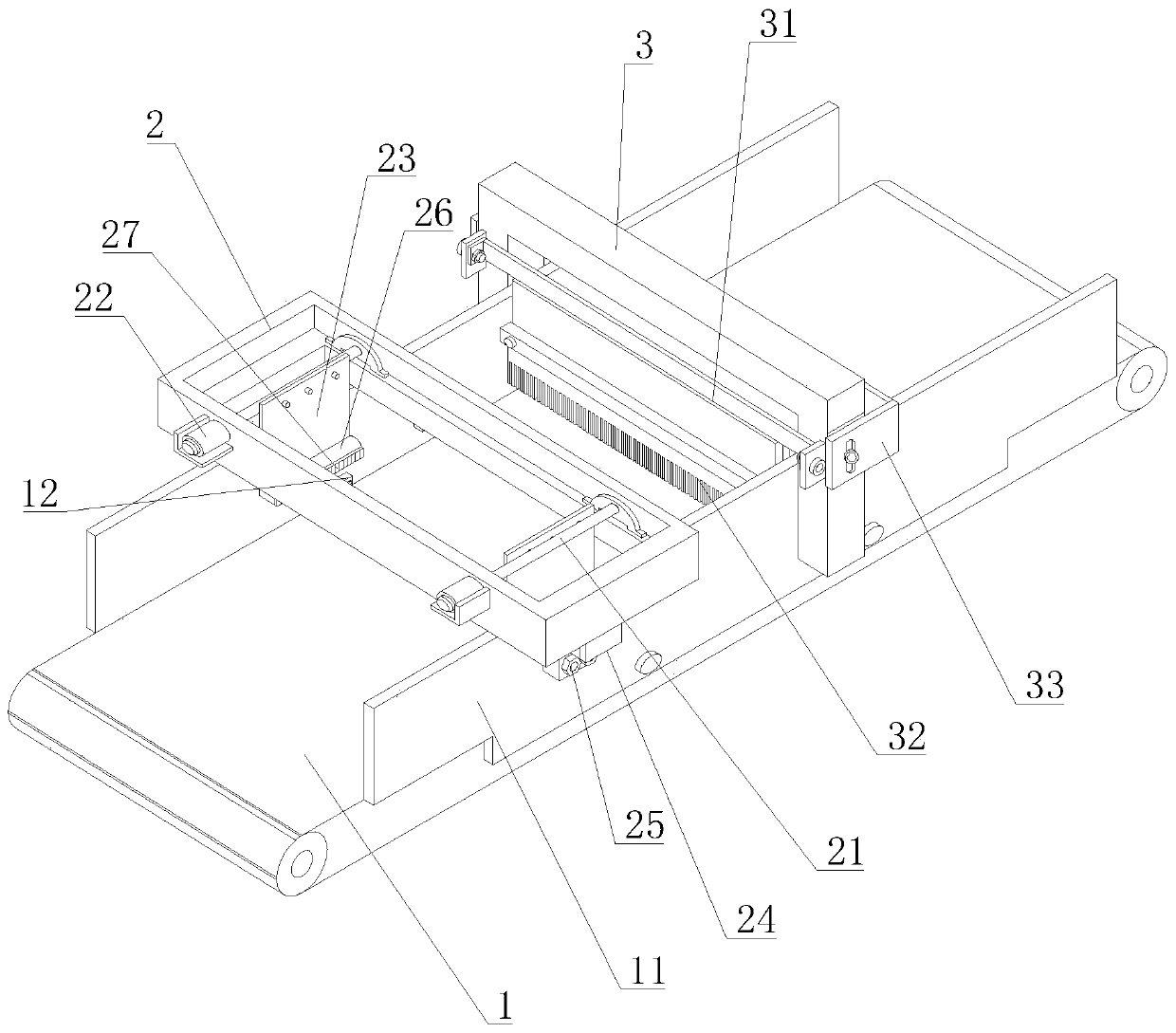

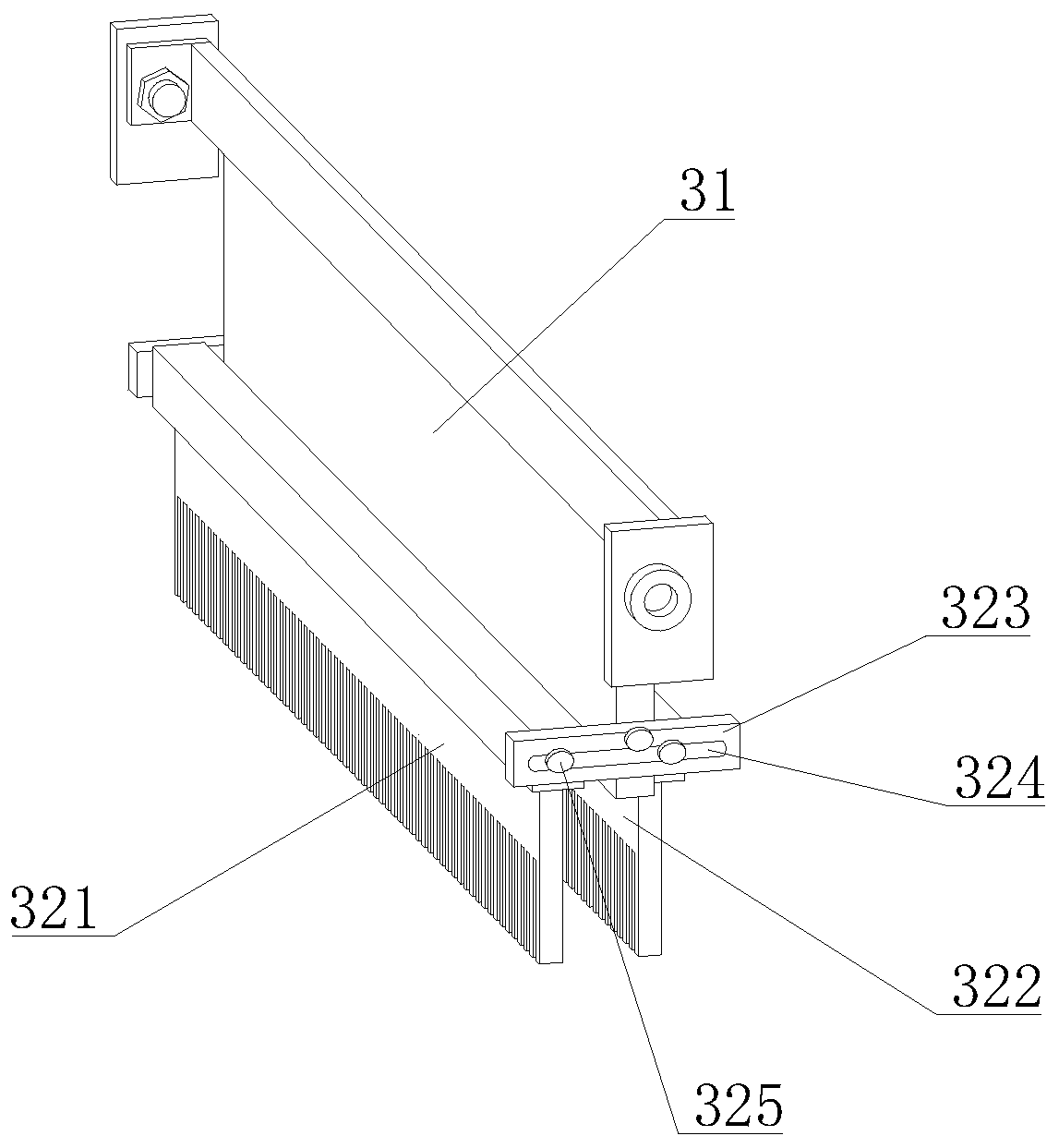

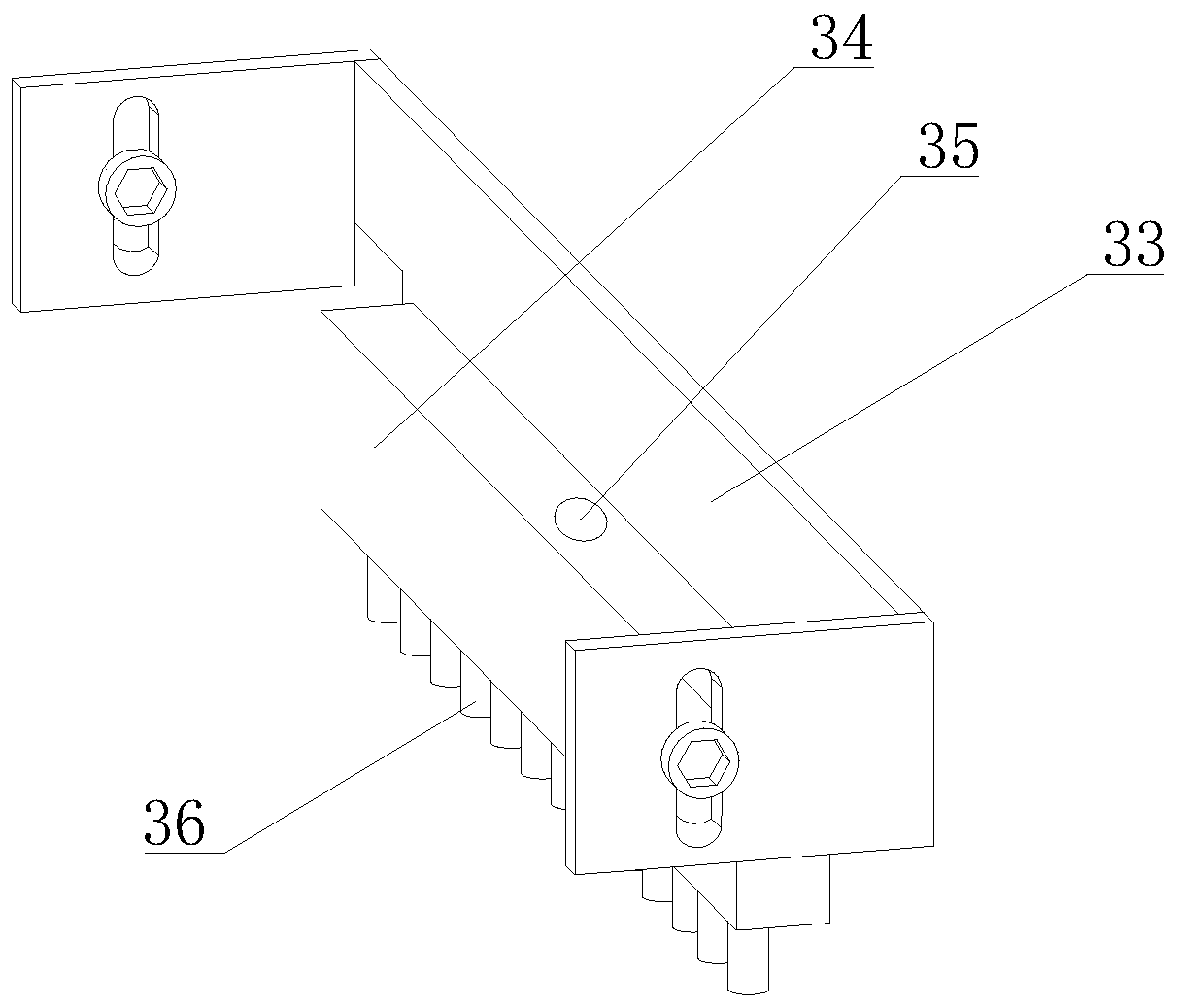

[0020] Such as Figure 1-4 As shown, a wooden block surface cleaning counting device includes a conveyor 1, and both sides of the conveyor 1 are provided with a baffle plate 11, and the baffle plate 11 is sequentially provided with an installation frame 2 and a gantry support 3 along the conveying direction; Both sides of the installation frame 2 are respectively connected to the baffle plate 11 through the connecting plate 24, the baffle plate 11 is provided with a vertical elongated hole, and the first hole for connecting the baffle plate 11 and the adjustment plate 23 is perforated in the elongated hole. screw 25. The connection plate 24 is connected with the baffle plate 11 by the first screw 25, and the first screw 25 can move up and down along the elongated hole to adjust the height of the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com