Method for controlling growth of microorganisms and/or biofilms in an industrial process

A biofilm and microbial technology, applied in the direction of adding anti-biological reagents, adding sludge control agents, preventing corrosion/sediment formation of pulping equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Embodiment 1 (reference)

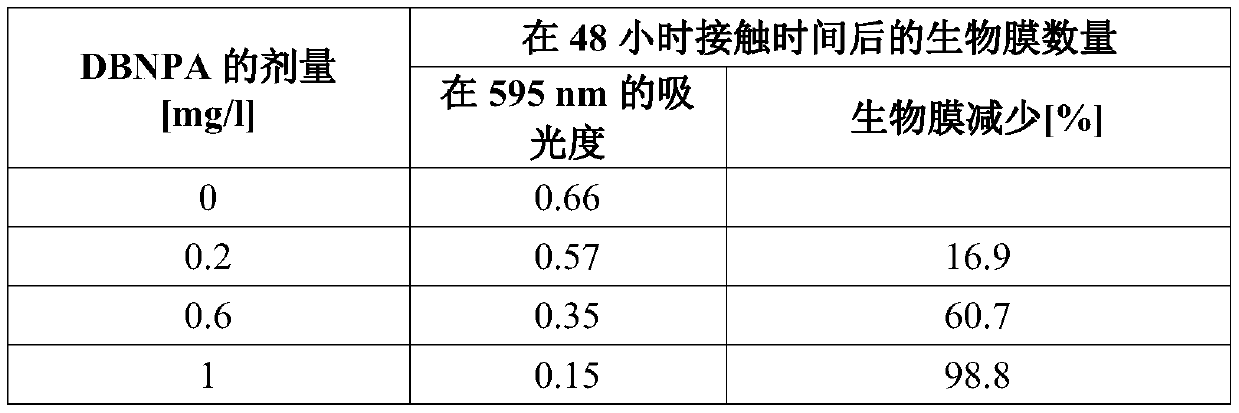

[0083] Tables 1 and 2 demonstrate the ability of the conventional antimicrobial agent DBNPA to prevent biofilm formation of Thermus rubrum (Meiothermus silvanus) and Pseudoxanthomonas taiwanensis. The test conditions simulate paper or board manufacturing process conditions (synthetic paper machine water, high temperature, presence of fibers, high fluidity). The conventional antimicrobial DBNPA requires an active compound dose of 1 mg / l to achieve acceptable or significant biofilm reduction efficacy. The results of DBNPA are given in Table 1 and Table 2.

[0084] Table 1 shows the effect of DPNPA dosage in SPW on Meiothermus silvanus biofilm at 45°C and 150 rpm (high mixing). Biofilms were stained and quantified by absorbance measurement. Doses are given as active ingredients.

[0085] Table 1

[0086]

[0087] Table 2 shows the effect of DPNPA dosage in SPW on Pseudoxanthomonas taiwanensis biofilm at 45°C and 150 rpm (high mixing). Bi...

Embodiment 2

[0090] Embodiment 2 (reference)

[0091] Tables 3 and 4 show the effect of the well-known antibiotic gramicidin on biofilm formation of Meiothermus silvanus and Pseudoxanthomonas taiwanensis. In the synthetic growth medium R2-broth, gramicidin was able to prevent biological film formation.

[0092] The results in Tables 3 and 4 demonstrate the expected behavior of clinical antimicrobial compounds with reduced performance when exposed to non-clinical conditions.

[0093] Table 3 shows the effect of gramicidin dosage on Meiothermus silvanus biofilm in R2-broth and SPW. Biofilms were stained and quantified by absorbance measurement. Doses are given as active ingredients.

[0094] table 3

[0095]

[0096] Table 4 shows the effect of gramicidin dosage on Pseudoxanthomonas taiwanensis biofilm in R2-broth and SPW. Biofilms were stained and quantified by absorbance measurement. Doses are given as active ingredients.

[0097] Table 4

[0098]

Embodiment 3

[0100] Tables 5 and 6 demonstrate the ability of Compound C and Compound E to prevent biofilm formation of Meiothermus silvanus and Pseudoxanthomonas taiwanensis. The test conditions are the same as those in Example 1. It was observed that Compound C and Compound E were able to control biofilms at very low concentrations. The biofilm reduction of active compound C or compound E at a dose of 0.2 mg / l was already more than 90%.

[0101] Table 5 shows the effect of Compound C dosage on Meiothermus silvanus biofilm in SPW at 45°C and 150 rpm (high mixing). Biofilms were stained and quantified by absorbance measurement. Compound C doses are given as active compound.

[0102] table 5

[0103]

[0104] Table 6 shows the effect of Compound E dosage on Meiothermus silvanus biofilm at 45°C and 150 rpm (high mixing). Biofilms were stained and quantified by absorbance measurement. Compound E doses are given as active compound.

[0105] Table 6

[0106]

[0107] The results i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com