Structured grid division method for rod bundle assembly with wire winding function

A technology of mesh division and component structure, applied in design optimization/simulation, image data processing, 3D modeling, etc., can solve problems such as rough surface of winding wire, achieve high mesh quality, reduce mesh number, and converge Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

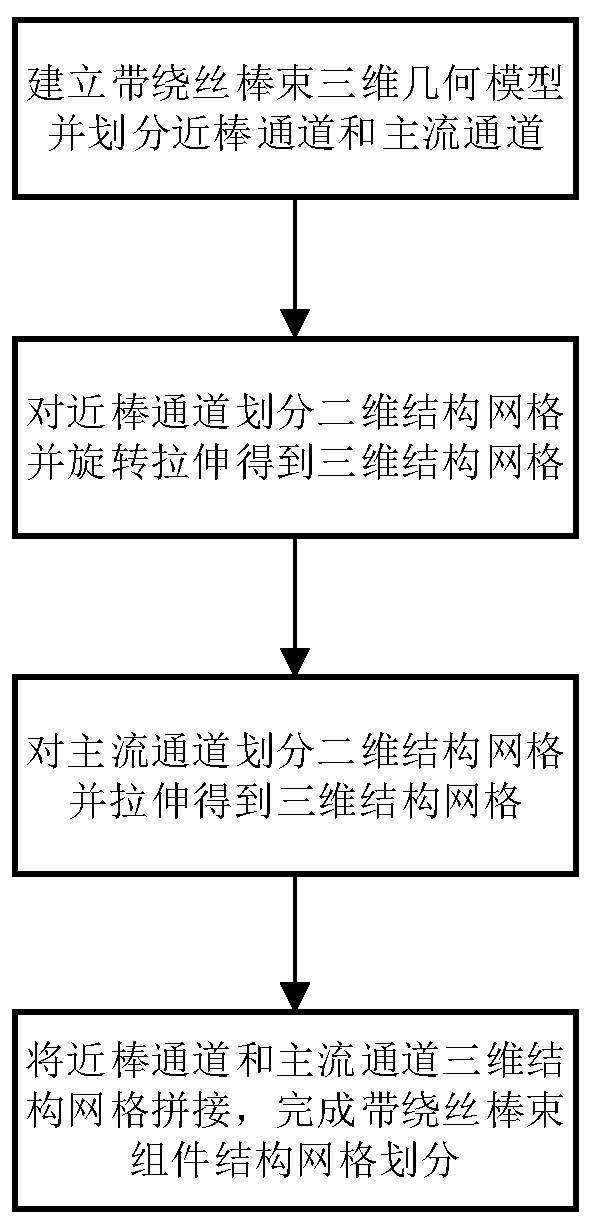

[0031] Combine below figure 1 In the flow chart shown, the present invention is further described in detail by taking the supercritical water reactor 2×2 wire-wound fuel assembly as an example. Specifically include the following steps:

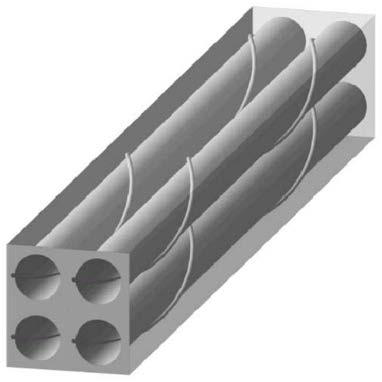

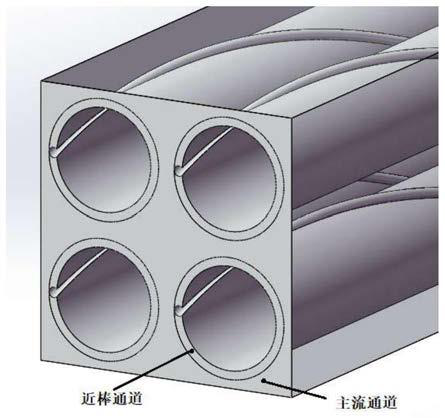

[0032] Step 1: Establish a three-dimensional geometric model of the supercritical pressurized water reactor with wire-wound 2×2 rod bundle components. When modeling, the geometric characteristics of the wire-wound need to be established. In this example, the length of the calculation area selected is 300mm, and the length of the two wire-wound pitches ,Such as diagram 2-1 As shown, the bundle assembly with wire-wrapped rods is divided into the near-rod channel containing the geometric features of the wire-wound and the mainstream channel without the geometric features of the wire-wound, as shown in Figure 2-2 As shown; the divided near-rod channel is composed of a circular cross-section channel that completely contains the geometric featur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com