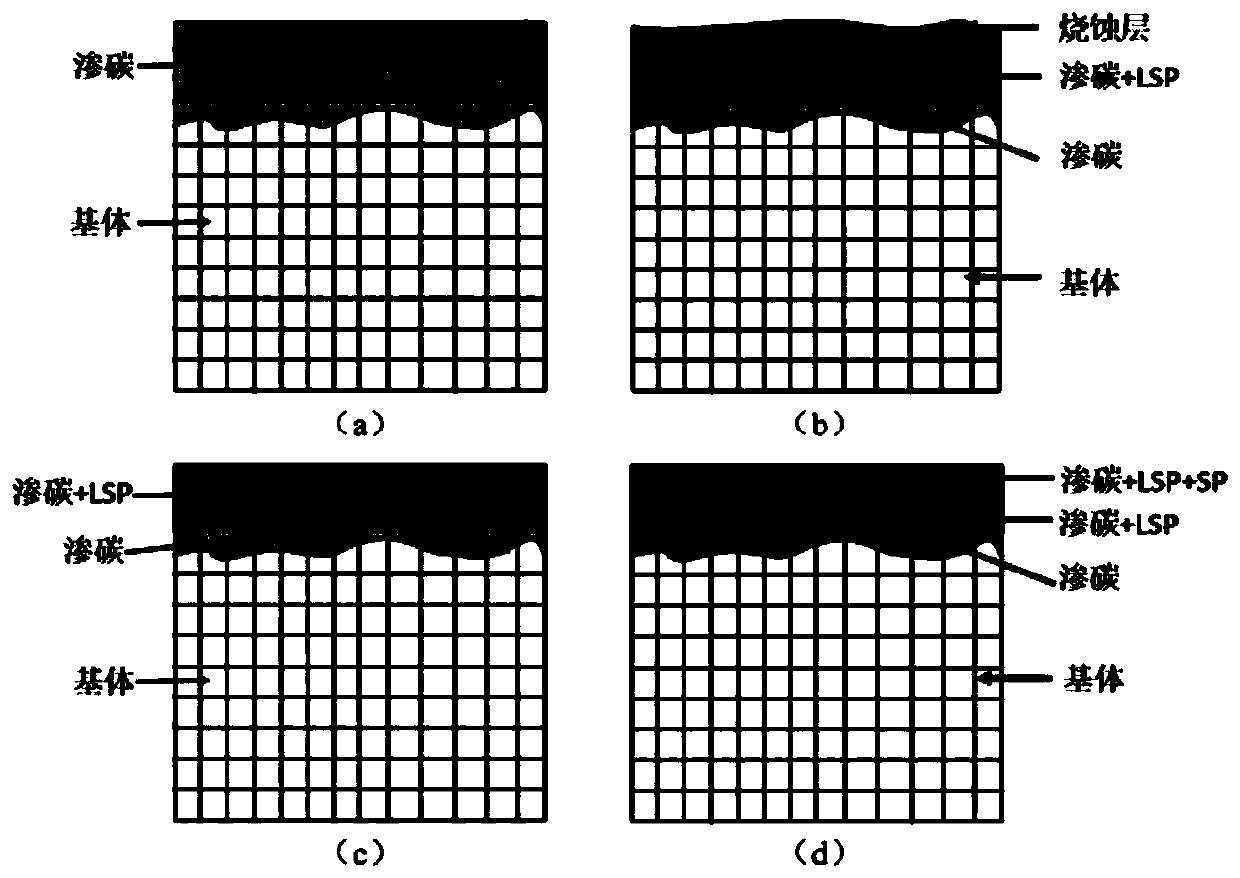

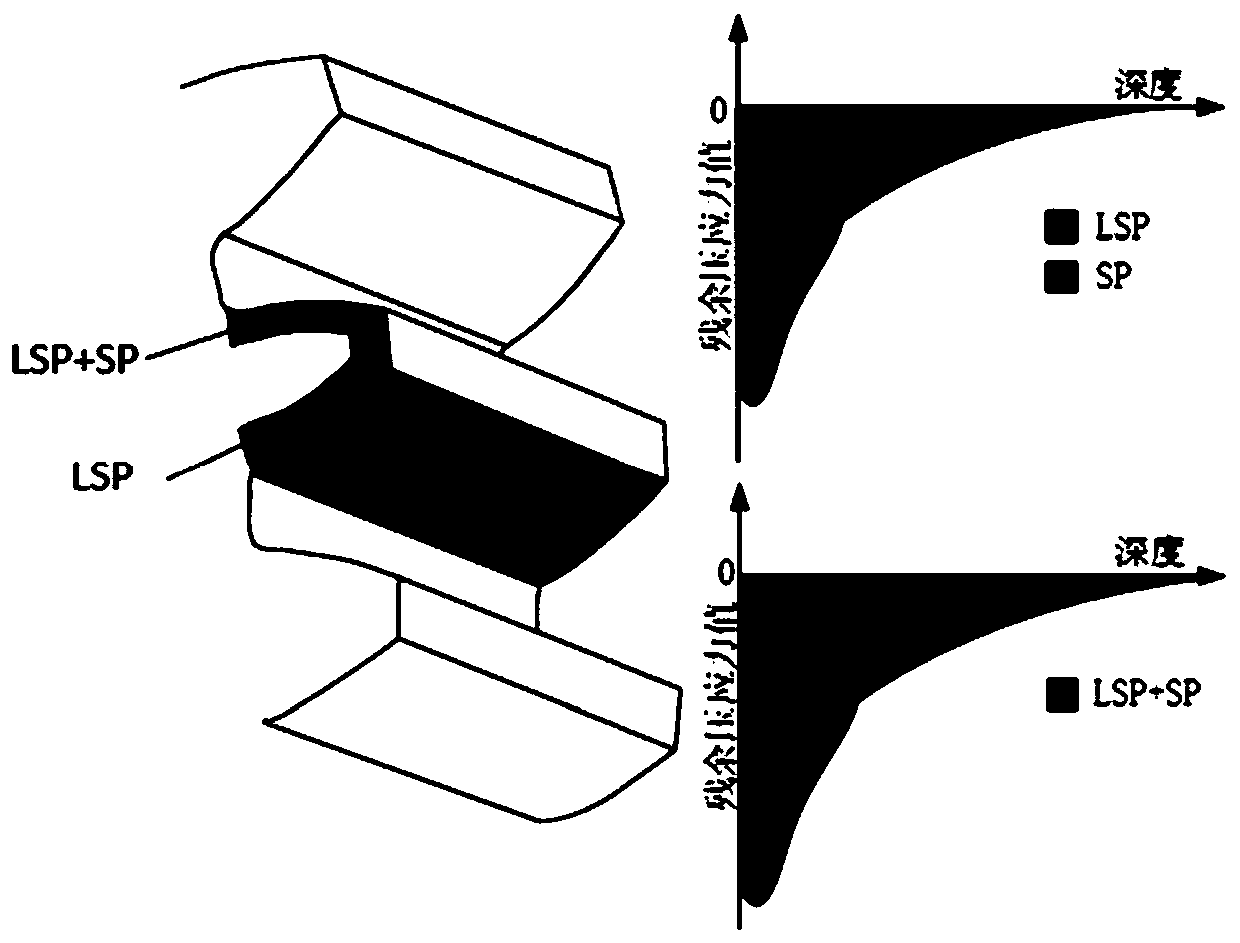

Method for improving anti-wear/anti-fatigue performance of carburized gear by utilizing comprehensive means

A carburizing gear and anti-wear technology, which is applied to components with teeth, belts/chains/gears, gear teeth, etc., can solve problems such as difficult to meet the use requirements, improve reliability and service life, and avoid lamination loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Carry out a comprehensive approach to the aero-engine gear, and the specific implementation steps are as follows:

[0031] 1. Clamp the gear on the laser shock strengthening equipment, and adjust the manipulator so that the laser shock strengthening area of the gear is roughly perpendicular to the light outlet;

[0032] 2. According to the laser parameters: laser wavelength 1064nm, pulse width 20ns, and gear material characteristics, set the laser power density to 5.5GW / cm 2 , the diameter of the spot is 2.4mm, the overlap rate of the spot is 50%, there is no absorbing protective layer on the gear surface, and the water-constrained layer is loaded, and the two-way laser shock strengthening with an angle of 45° to the normal vertical line of the gear tooth surface is carried out.

[0033] 3. Install the strengthened gear on the fixture of the grinding machine, the amount of feed is 0.03mm at one time, and the amount of feed is 0.01mm at the last time, to complete the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com