Method for preparing foam concrete from iron tailings and aerated concrete wastes

A technology of air-entrained concrete and foam concrete, which is applied in the field of building materials, can solve problems such as environmental threats and occupation of land resources, and achieve good sound insulation, simple process flow, and good thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

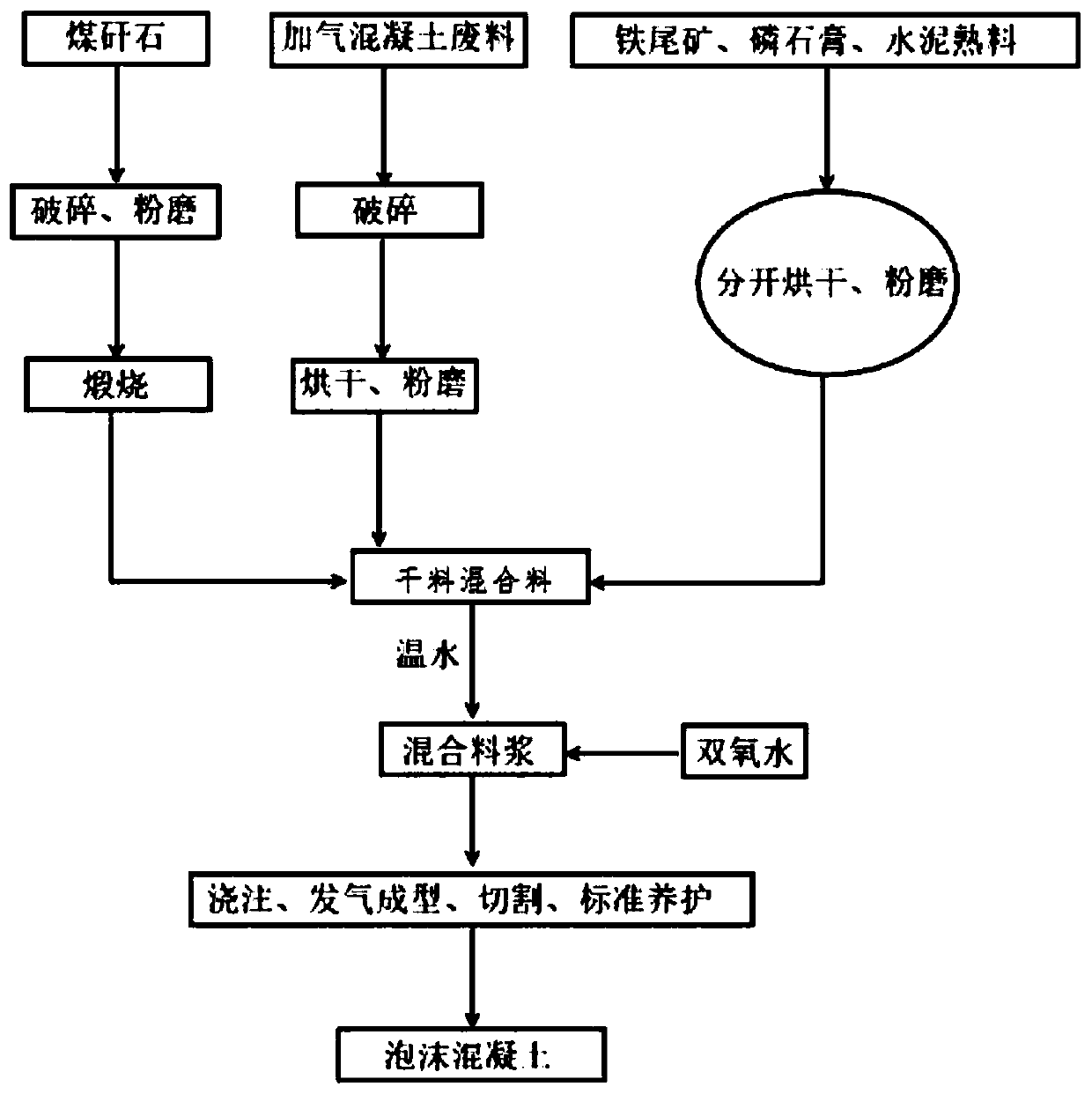

Method used

Image

Examples

Embodiment 1

[0061] Step 1. Use jaw crusher to crush coal gangue to 2 / kg, then the ground material is calcined at 1000°C to obtain coal gangue base material.

[0062] Step 2: Use a jaw crusher to crush the aerated concrete waste to 2 / kg, to obtain aerated concrete waste base material.

[0063] Wherein, the drying temperature of the aerated concrete waste is 45° C., and the water content is less than 0.1%; the grinding machine is a SMΦ500mm×500mm cement mill.

[0064] Step 3: Dry the iron tailings and grind them to a specific surface area of 550m 2 / kg; After drying the phosphogypsum, it is ground to a specific surface area of 300m 2 / kg; dry the cement clinker and grind it to a specific surface area of 700m 2 / kg; Mix the above-mentioned pretreated materials with coal gangue base material and aerated concrete waste base material to obtain a dry mix;

[0065] Wherein, the drying temperature is 45°C, and drying to a moisture content of less than 0.1%; the grinding machine is a SMΦ500mm×500mm ...

Embodiment 2

[0077] Step 1. Use jaw crusher to crush coal gangue to 2 / kg, then the ground material is calcined at 1000°C to obtain coal gangue base material.

[0078] Step 2: Use a jaw crusher to crush the aerated concrete waste to 2 / kg, to obtain aerated concrete waste base material.

[0079] Wherein, the drying temperature of the aerated concrete waste is 50° C., and the water content is less than 0.1%; the grinding machine is a cement mill of SMΦ500mm×500mm.

[0080] Step 3: Dry the iron tailings and grind to a specific surface area of 600m 2 / kg; After drying the phosphogypsum, it is ground to a specific surface area of 350m 2 / kg; dry the cement clinker and grind it to a specific surface area of 650m 2 / kg; Mix the above-mentioned pretreated material with coal gangue base material and aerated concrete waste base material to obtain a dry mix;

[0081] Wherein, the drying temperature is 50°C, and the moisture content is less than 0.1%; the grinding machine is a SMΦ500mm×500mm cement mill...

Embodiment 3

[0093] Step 1. Use jaw crusher to crush coal gangue to 2 / kg, then the ground material is calcined at 900°C to obtain coal gangue base material.

[0094] Step 2: Use a jaw crusher to crush the aerated concrete waste to 2 / kg, to obtain aerated concrete waste base material.

[0095] Wherein, the drying temperature of the aerated concrete waste is 50° C., and the water content is less than 0.1%; the grinding machine is a cement mill of SMΦ500mm×500mm.

[0096] Step 3: Dry the iron tailings and grind them to a specific surface area of 800m 2 / kg; After drying the phosphogypsum, it is ground to a specific surface area of 400m 2 / kg; dry the cement clinker and grind it to a specific surface area of 600m 2 / kg; Mix the above-mentioned pretreated material with coal gangue base material and aerated concrete waste base material to obtain a dry mix;

[0097] Wherein, the drying temperature is 50°C, and the moisture content is less than 0.1%; the grinding machine is a SMΦ500mm×500mm cement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com