Automatic upper pulling machine

A pull-up machine and automatic technology, which is applied to shoe-making machinery, apparel, and shoe-bonding parts, etc., can solve the problems of wasting human resources, low work efficiency, and waste formation, and achieve the effect of saving labor costs and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the drawings and embodiments. The same parts are indicated by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top" "Face", "inner" and "outer" respectively refer to directions toward or away from the geometric center of a particular component.

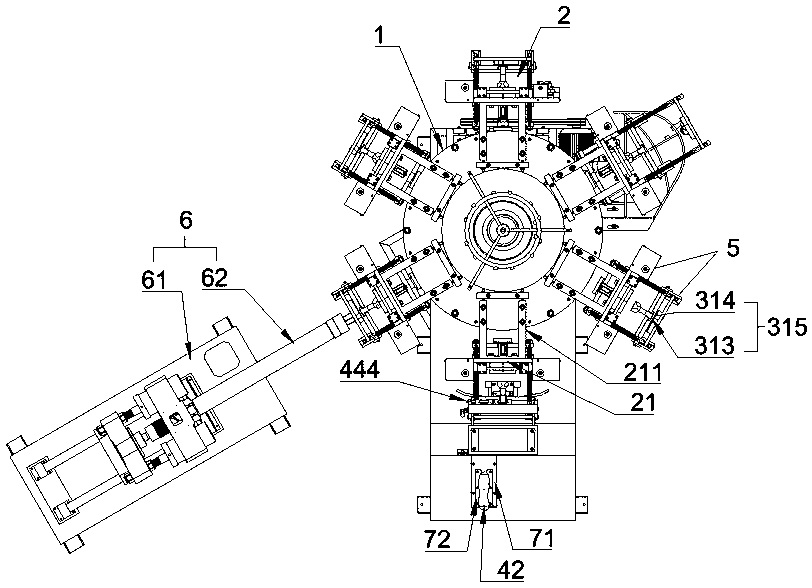

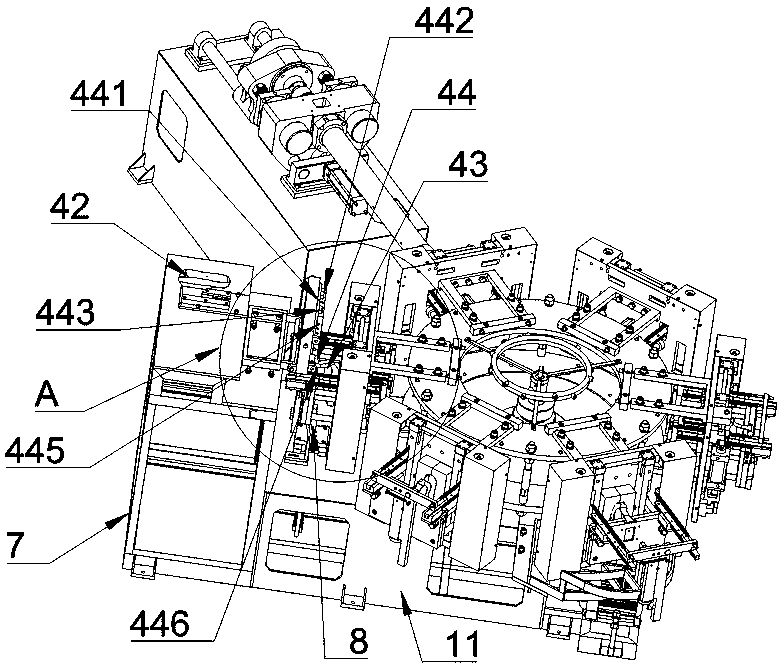

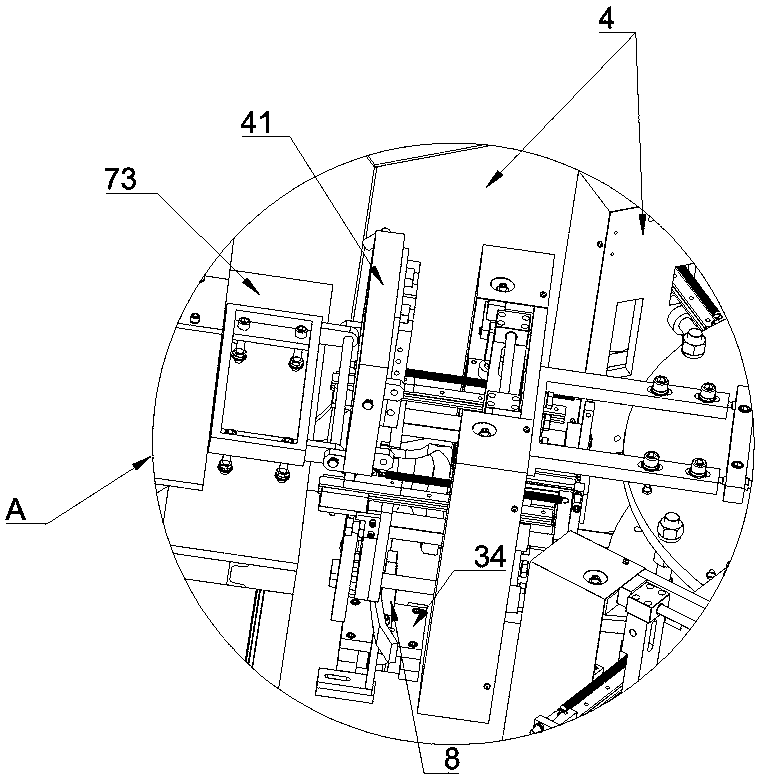

[0025] Reference Figure 1 to 6 As shown, an automatic lasting machine of this embodiment includes a rotating body 1 and a plurality of shoe mold fixing assemblies 2 arranged on the side of the rotating body 1, and the shoe mold fixing assembly 2 takes the center of the rotating body 1 as its axis. Distributed in a circular array, a supporting base 11 for supporting the rotating body 1 is arranged under the rotating body 1, and a mold changing assembly 4, a driving assembly 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com