Process method for preparing multilayer SiNx back film by solar single crystal PERC

A process method, solar technology, applied in sustainable manufacturing/processing, final product manufacturing, photovoltaic power generation, etc., can solve the problems of solar cell lowering refractive index, poor film uniformity effect, etc., to achieve lower refractive index, convenient coating , the effect of improving energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

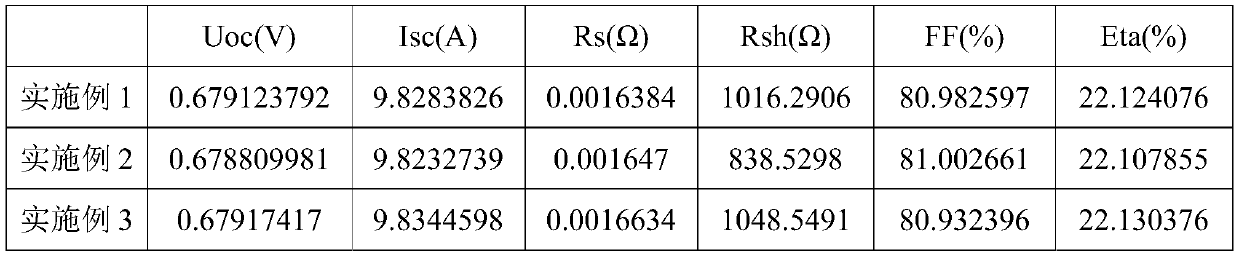

Embodiment 1

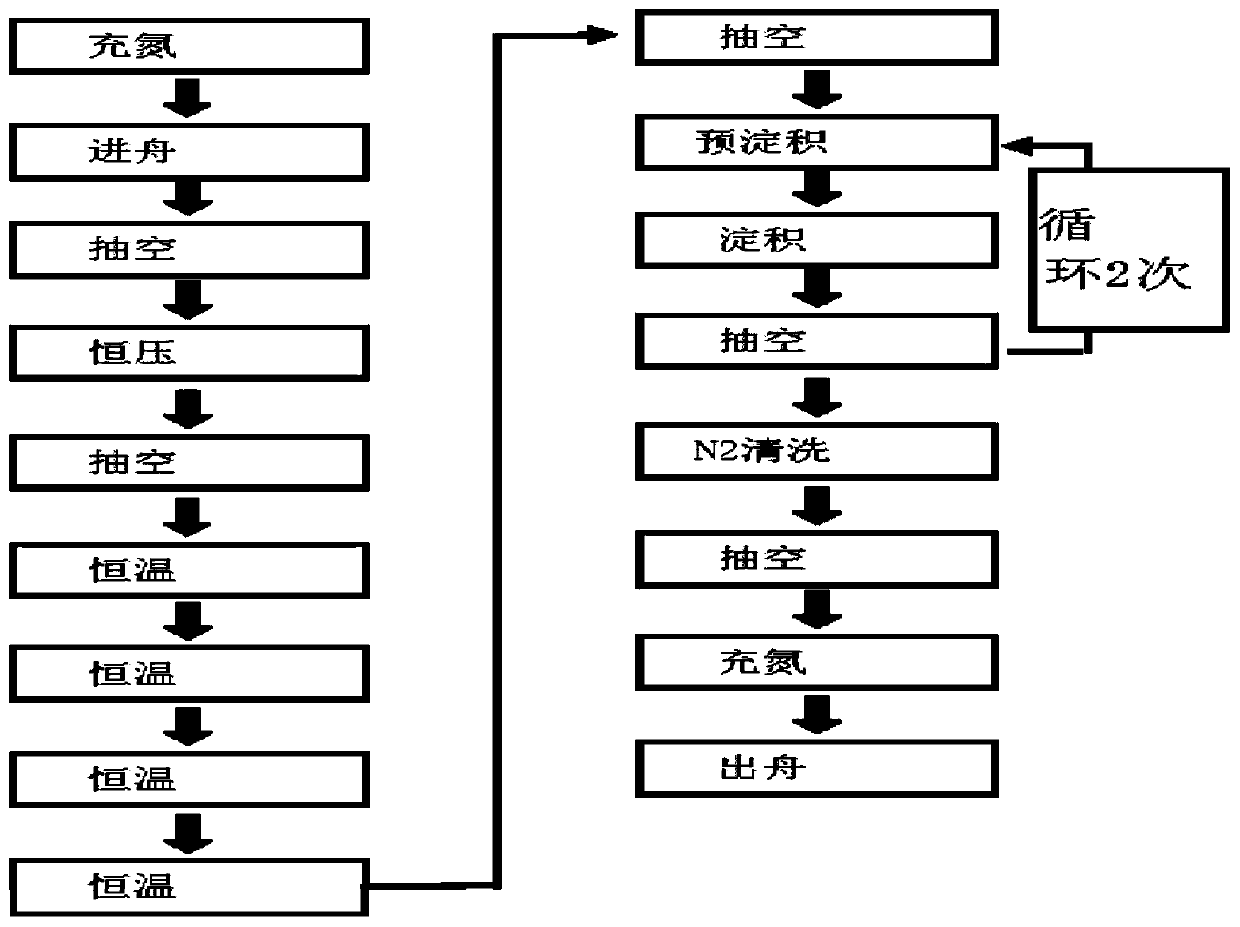

[0060] Multi-layer SiN for solar monocrystalline PERC x The back film process includes the following steps:

[0061] a) Nitrogen filling: Nitrogen is filled to keep the furnace tube at atmospheric pressure;

[0062] b) Entering the boat: sending the full furnace of silicon wafers into the PECVD furnace tube;

[0063] c) Evacuation: pump out all the gas in the furnace tube, so that the tube is in a vacuum state;

[0064] d) Constant pressure: make the pressure obtain a stable state;

[0065] e) Evacuation: evacuate again to make the vacuum state in the tube stable;

[0066] f) Constant temperature: multi-step constant temperature operation (four times), so that the temperature in the tube is controlled and finally reaches a stable state;

[0067] g) Evacuation: Use PD305 machine <80mTorr to evacuate to prepare for pre-deposition;

[0068] h) Pre-deposition: using SiH 4 and NH 3 The silicon wafer is pre-deposited, the coating temperature is 450.0°C, the coating time is 20...

Embodiment 2

[0083] Multi-layer SiN for solar monocrystalline PERC x The back film process includes the following steps:

[0084] a) Nitrogen filling: Nitrogen is filled to keep the furnace tube at atmospheric pressure;

[0085] b) Entering the boat: sending the full furnace of silicon wafers into the PECVD furnace tube;

[0086] c) Evacuation: pump out all the gas in the furnace tube, so that the tube is in a vacuum state;

[0087] d) Constant pressure: make the pressure obtain a stable state;

[0088] e) Evacuation: evacuate again to make the vacuum state in the tube stable;

[0089]f) Constant temperature: multi-step constant temperature operation (four times), so that the temperature in the tube is controlled and finally reaches a stable state;

[0090] g) Evacuation: Use PD305 machine <80mTorr to evacuate to prepare for pre-deposition;

[0091] h) Pre-deposition: using SiH 4 and NH 3 The silicon wafer is pre-deposited, the coating temperature is 460.0°C, the coating time is 20s...

Embodiment 3

[0105] Multi-layer SiN for solar monocrystalline PERC x The back film process includes the following steps:

[0106] a) Nitrogen filling: Nitrogen is filled to keep the furnace tube at atmospheric pressure;

[0107] b) Entering the boat: sending the full furnace of silicon wafers into the PECVD furnace tube;

[0108] c) Evacuation: pump out all the gas in the furnace tube, so that the tube is in a vacuum state;

[0109] d) Constant pressure: make the pressure obtain a stable state;

[0110] e) Evacuation: evacuate again to make the vacuum state in the tube stable;

[0111] f) Constant temperature: multi-step constant temperature operation (four times), so that the temperature in the tube is controlled and finally reaches a stable state;

[0112] g) Evacuation: Use PD305 machine <80mTorr to evacuate to prepare for pre-deposition;

[0113] h) Pre-deposition: using SiH 4 and NH 3 The silicon wafer is pre-deposited, the coating temperature is 430.0°C, the coating time is 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com