A kind of lithium-ion supercapacitor pre-embedded lithium method

A supercapacitor and lithium-ion technology, applied in capacitors, electrolytic capacitors, hybrid capacitors, etc., can solve the problems of device rate performance impact, high cost of environmental control, volume change, etc., and achieve the effect of uncontrollable lithium doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

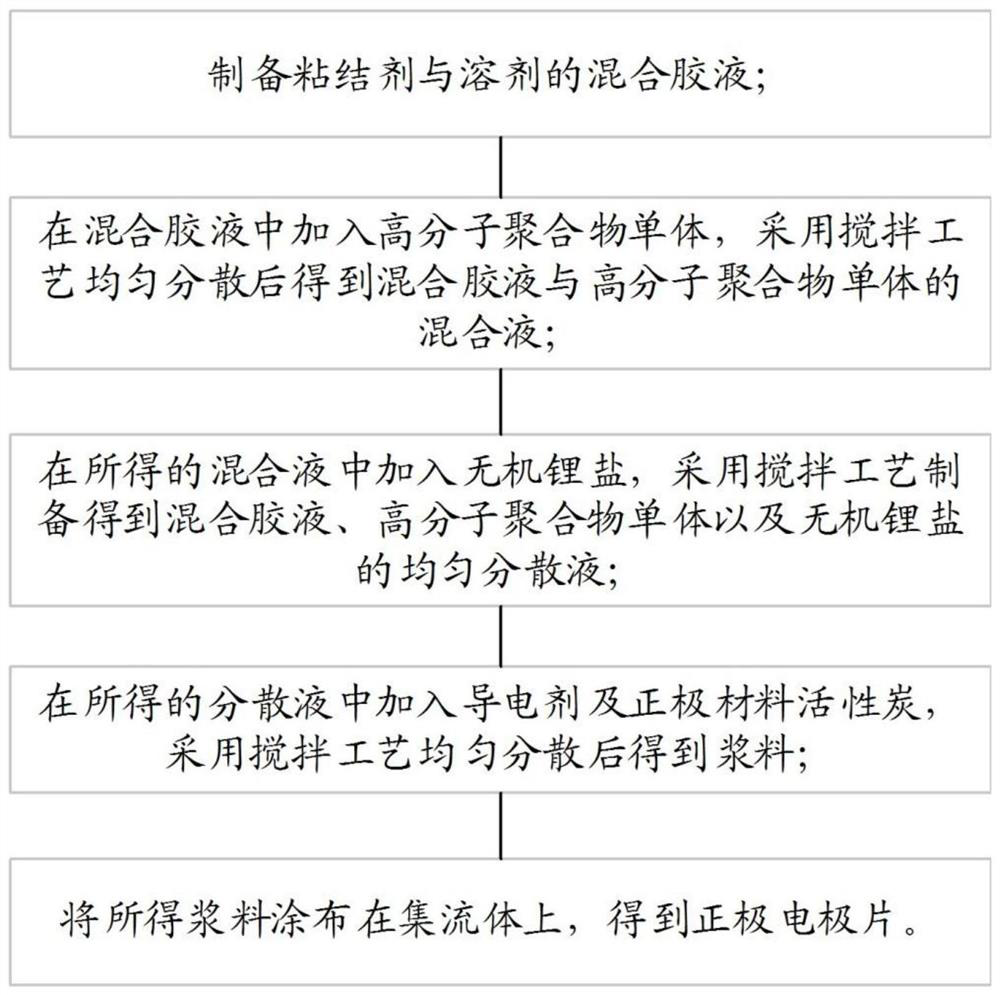

[0029] figure 1 A schematic flow chart of a lithium-ion supercapacitor pre-intercalation lithium method provided for the implementation of the present invention. like figure 1 Shown, this method comprises the preparation method of positive electrode sheet, and its step comprises:

[0030] Prepare the mixed glue solution of binder (binder includes but not limited to PVdf, CMC, PVA, PTFE, LA series and polyimide, etc.) and solvent (solvent includes but not limited to NMP, water, etc.) by stirring process; Wherein, the binder content accounts for 5-8%.

[0031] Add high molecular polymer monomers (high molecular polymer monomers include but not limited to aniline, pyrrole, thiophene, naphthalene, pyrene, phenanthrene, perylene and their derivatives) to the above glue, and use a stirring process to evenly disperse to obtain the glue The mixed solution of liquid and high molecular polymer monomer; the content of high molecular polymer monomer accounts for 4-15%.

[0032] In the...

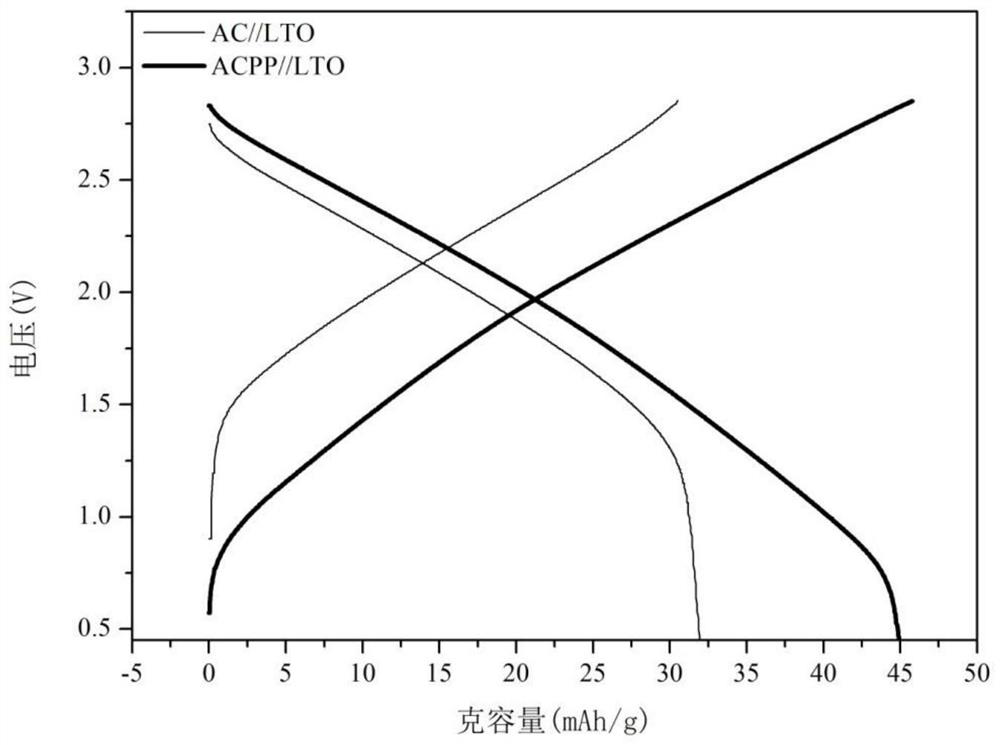

Embodiment 1

[0052] 1. Preparation of positive electrode sheet:

[0053] Prepare the mixed glue of binder PVdf and solvent NMP by stirring process;

[0054] Add high molecular polymer monomer pyrene to the above-mentioned glue solution, and obtain a mixed solution of glue solution and high molecular polymer monomer pyrene after being uniformly dispersed by a stirring process;

[0055] In the mixed solution of step (2) gained, add inorganic lithium salt Li 3 PO 4 , using a stirring process to prepare glue, polymer monomer pyrene and inorganic lithium salt Li 3 PO 4 homogeneous dispersion;

[0056] Add conductive agent Ketjen black and positive electrode material activated carbon to the mixed solution obtained in step (3), and obtain a slurry suitable for coating after being uniformly dispersed by a stirring process;

[0057] Coat the slurry obtained in step (4) on the corroded aluminum foil to obtain a surface density of 3 to 4 mg / cm 2 positive electrode sheet;

[0058] Cut the posit...

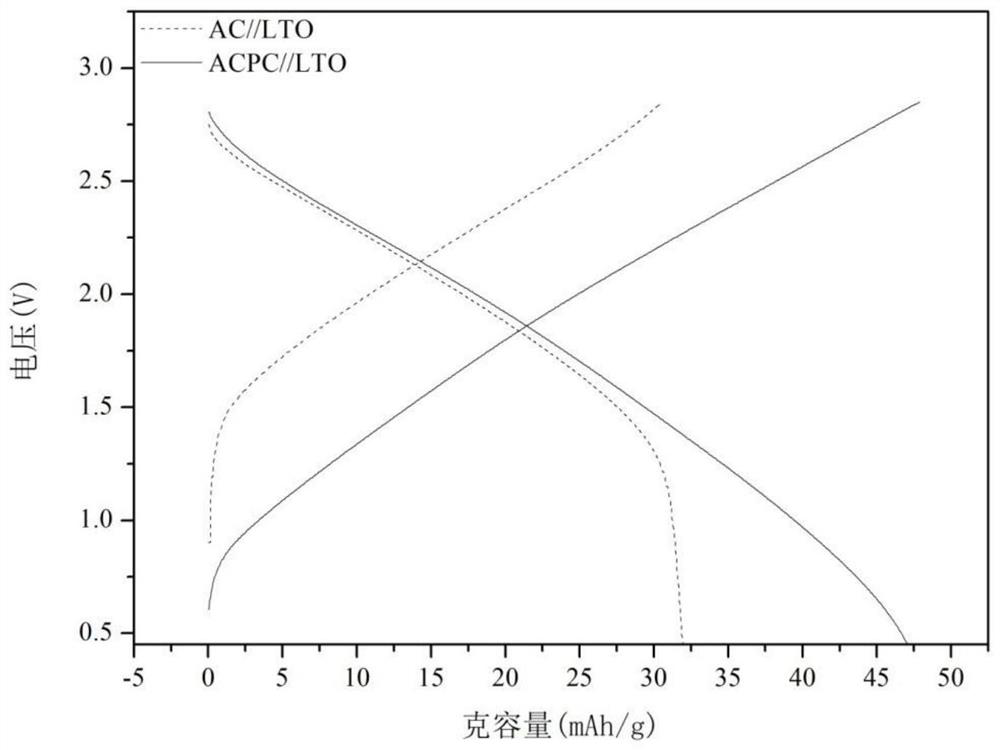

Embodiment 2

[0077] 1. Preparation of positive electrode sheet:

[0078] Prepare the mixed glue of binder PVdf and solvent NMP by stirring process;

[0079] Add high molecular polymer monomer pyrene to the above-mentioned glue solution, and obtain a mixed solution of glue solution and high molecular polymer monomer pyrene after being uniformly dispersed by a stirring process;

[0080] In the mixed solution of step (2) gained, add inorganic lithium salt Li 2 CO 3 , using a stirring process to prepare glue, polymer monomer pyrene and inorganic lithium salt Li 2 CO 3 homogeneous dispersion;

[0081] Add conductive agent Ketjen black and positive electrode material activated carbon to the mixed solution obtained in step (3), and obtain a slurry suitable for coating after being uniformly dispersed by a stirring process;

[0082] Coat the slurry obtained in step (4) on the corroded aluminum foil to obtain a surface density of 3 to 4 mg / cm 2 positive electrode sheet;

[0083] Cut the posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com