Shielding cable provided with wound copper foil layer

A technology of shielding cables and copper foil layers, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor shielding performance and high production costs, and achieve the effects of remarkable shielding performance, prolonging service life and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention provides a shielded cable with a wound copper foil layer. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to make it easier to understand and grasp.

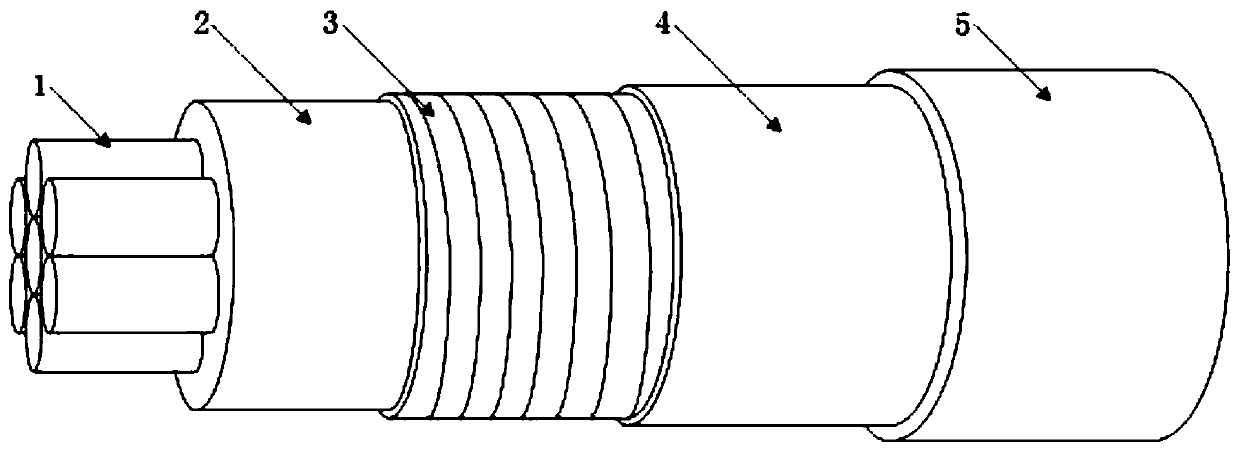

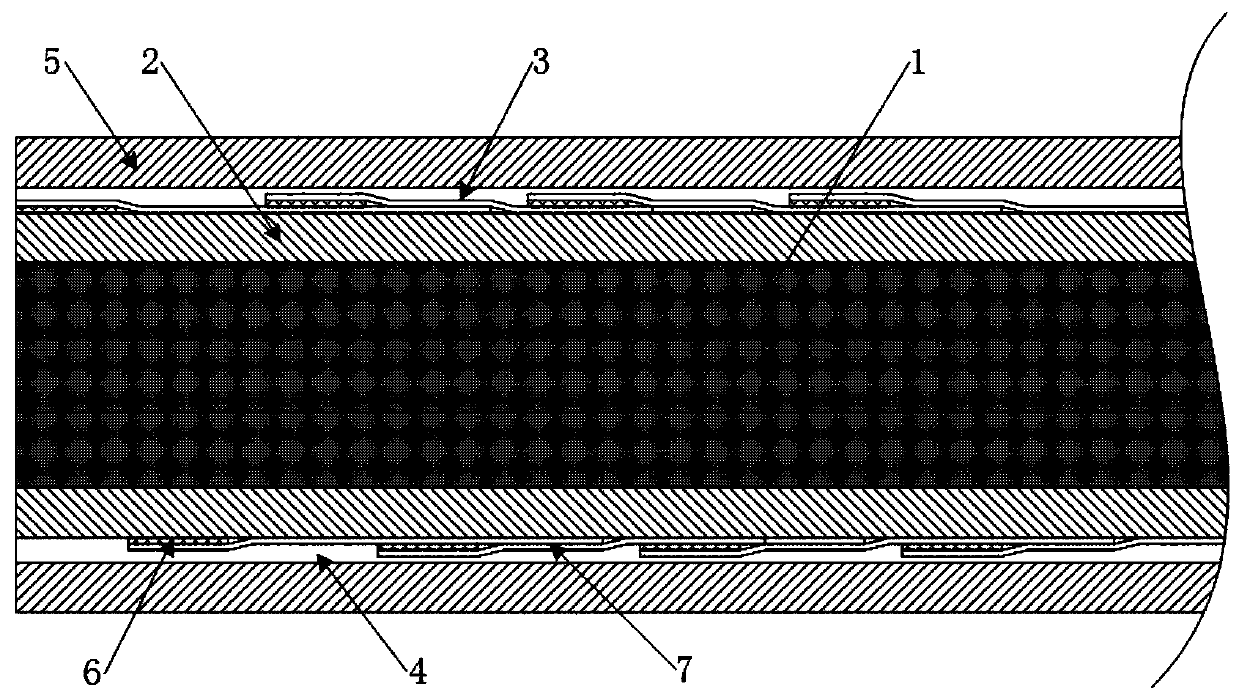

[0017] Shielded cables with a copper foil layer such as figure 1 with figure 2 As shown, it includes a PTFE core wire 2 with several guide cores 1 inside. The outer periphery of the PTFE core wire 2 is seamlessly wound with a rolled copper foil tape 3, and the outer periphery of the rolled copper foil tape 3 is provided with a protective agent curing sleeve 4, and the protective agent is cured. The outer periphery of the cover 4 is provided with a PVC protective cover 5 .

[0018] The specific implementation process and principle description:

[0019] The molding of the PTFE core wire 2 is extrusion molding, that is, extrusion wrapping of PTFE material is performed on the guide core 1 to form the PTFE core wire 2. This...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com