Long-range surface shape detector and detection method

A long-range surface and detector technology, applied in instruments, measuring devices, optical devices, etc., can solve problems such as many errors, uneven processing of pixel points of area array detectors, inconsistent photoelectric response efficiency, and electronic circuit consistency. , to achieve the effect of reducing system errors and overcoming them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

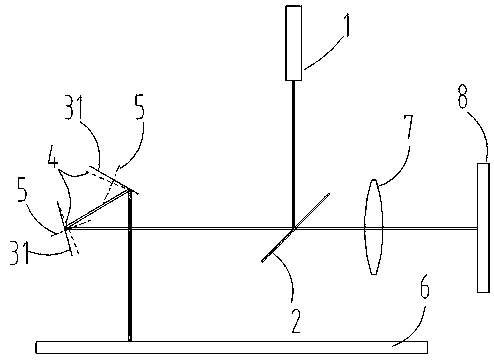

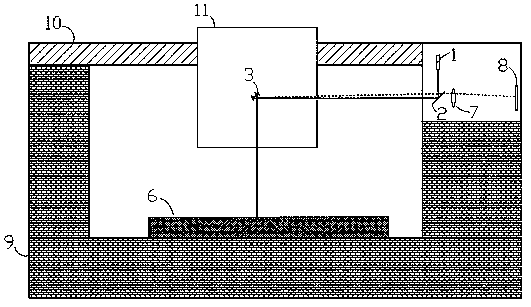

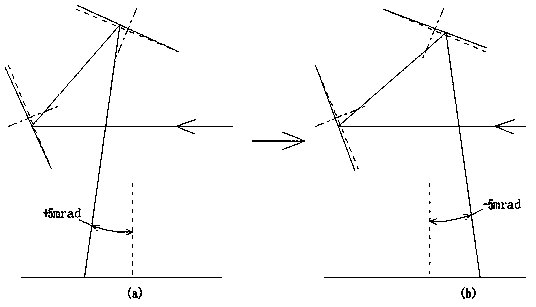

[0030] See figure 1 , figure 2, the long-range surface shape detector of the specific embodiment is used to carry out surface shape detection on the surface of the optical device 6 to be tested. The long-range surface shape detector includes a light source 1, a beam splitter 2, and a double reflection surface 4 constituting a pentaprism-like structure The double-mirror unit 3 and the f-θ angle detection system, the f-θ angle detection system includes a Fourier transform lens 7 and an array detector 8; the outgoing light beam provided by the light source 1 is reflected to the described beam splitter 2 The double-mirror unit 3 is then reflected to the surface of the optical device 6 to be tested by the double-mirror unit 3, reflected by the surface of the optical device 6 to be tested, and then reflected to the beam spli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com