Wear-resistant and anti-scouring gate valve

An anti-scour and wear-resistant technology, applied in sliding valves, valve details, valve devices, etc., can solve the problems of large erosion, poor sealing performance, easy wear, etc., to reduce flow rate, reduce wear and erosion damage, and achieve reliable sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

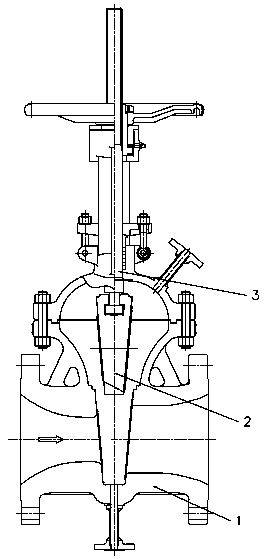

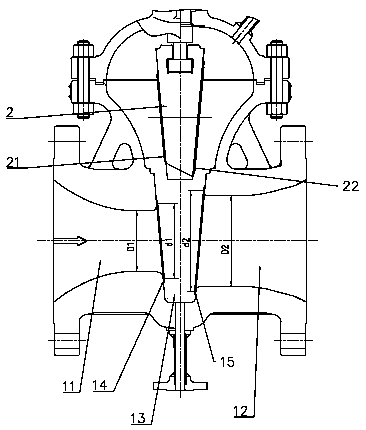

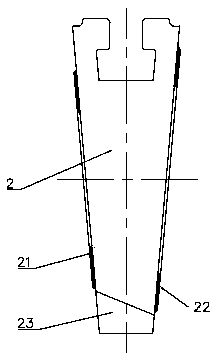

[0022] Such as Figure 1-2 As shown, a wear-resistant and anti-scouring gate valve includes a valve body 1, a gate plate 2, a valve stem 3 and a driving device. The valve body 1 includes an inlet channel 11, an outlet channel 12 and a middle chamber 13. The inlet channel The outlet end of 11 is provided with inlet valve seat 14, and the inlet end of described outlet channel 12 is provided with outlet valve seat 15; The inlet sealing surface 21 of sealing fit, and the outlet sealing surface 22 capable of sealingly fitting with the outlet valve seat 15 is formed on the other end surface; Moving up and down.

[0023] The driving device can be an automatically driven valve actuator, or a handwheel structure can be used to realize manual operation. The valve stem 3 is rotated by the driving device, and the valve stem 3 moves up and down through the cooperation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com